Electric connection structure making method and integrated circuit chip

A technology for electrical connection structures and chips, applied in circuits, electrical components, electrical solid devices, etc., can solve problems that affect the yield and reliability, increase the stress of integrated circuit films, and warping of films, so as to improve reliability and Yield rate, avoiding aluminum-silicon mutual dissolution and other structural defects, suitable for mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

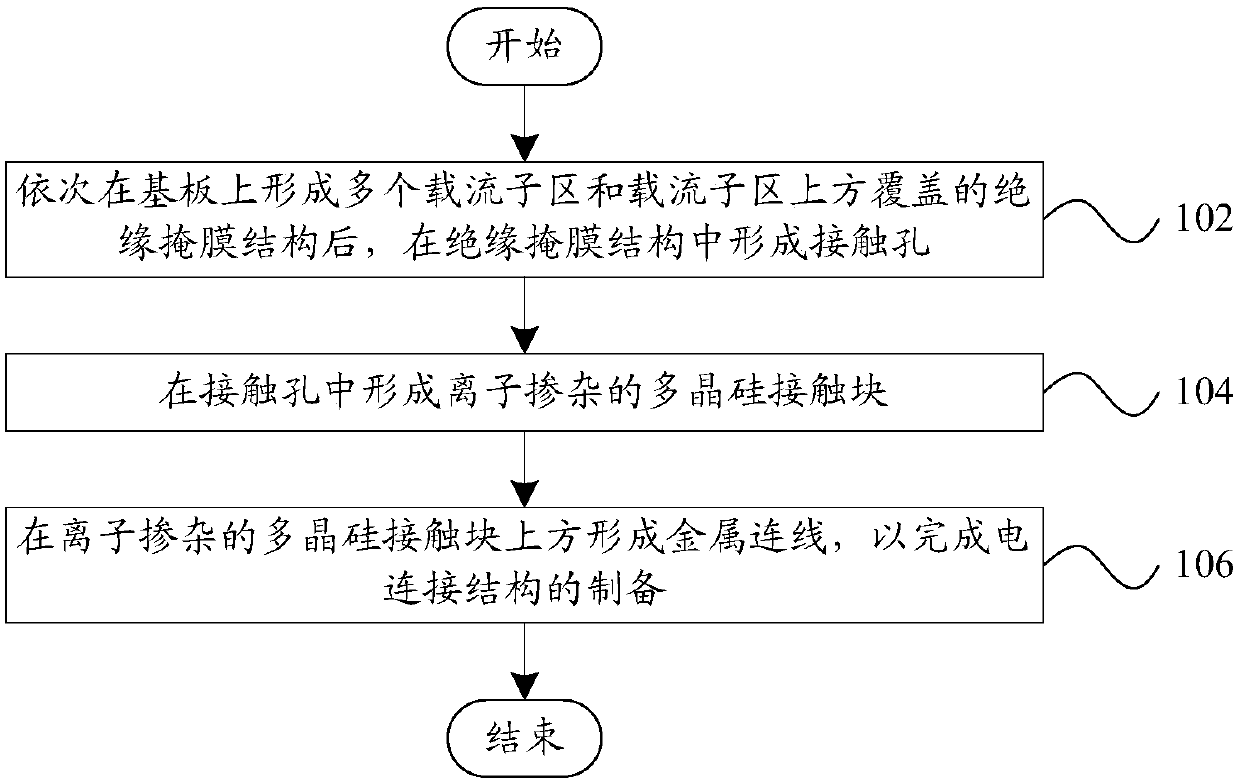

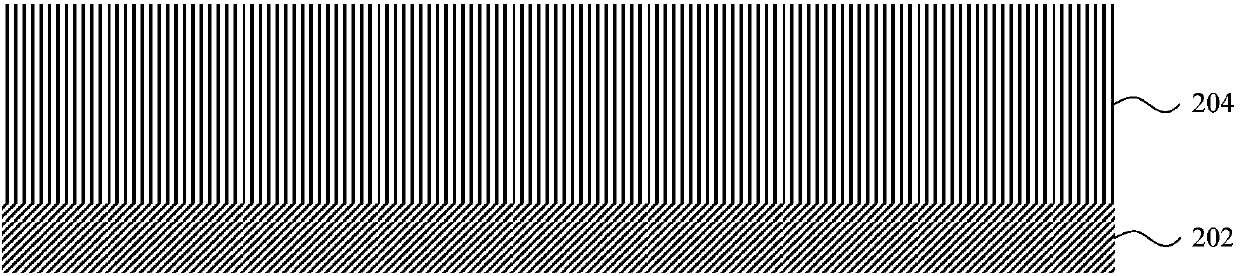

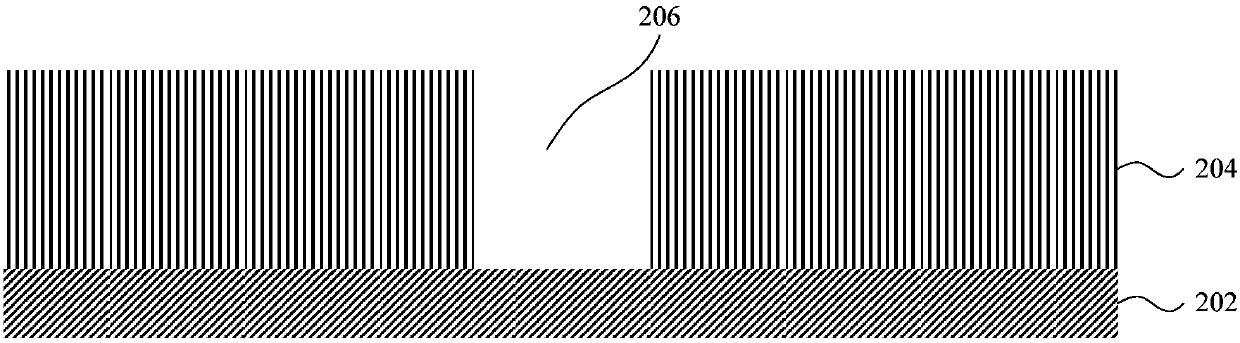

[0039] Such as figure 1 As shown, the method for preparing an electrical connection structure according to an embodiment of the present invention includes: step 102, after sequentially forming a plurality of carrier regions and an insulating mask structure covering the carrier regions on the substrate, Forming a contact hole in the film structure; Step 104, forming an ion-doped polysilicon contact block in the contact hole; Step 106, forming a metal connection on the ion-doped polysilicon contact block to complete the preparation of the electrical connection structure.

[0040] In this technical scheme, an ion-doped polysilicon contact block is formed in the contact hole, and a metal connection is formed above the ion-doped polysilicon contact block, thereby forming an electrical connection between the bottom carrier region and the top metal connection. contact, avoiding the filling of metal atoms in the contact hole, thereby avoiding the mutual dissolution of aluminum and sil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com