ZnO nanometer array ultraviolet detector and manufacturing method thereof

A technology of ultraviolet detectors and nano-arrays, applied in semiconductor devices, final product manufacturing, sustainable manufacturing/processing, etc., can solve cumbersome and expensive problems, and achieve easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

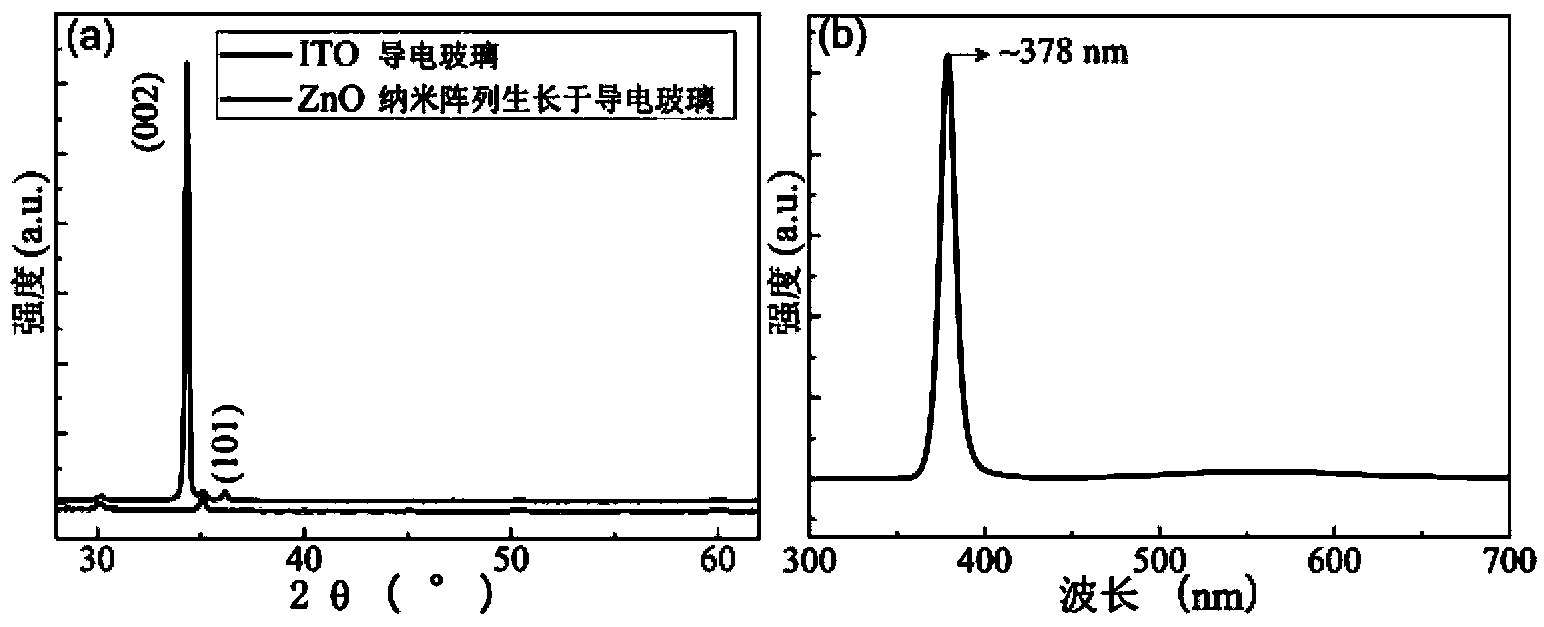

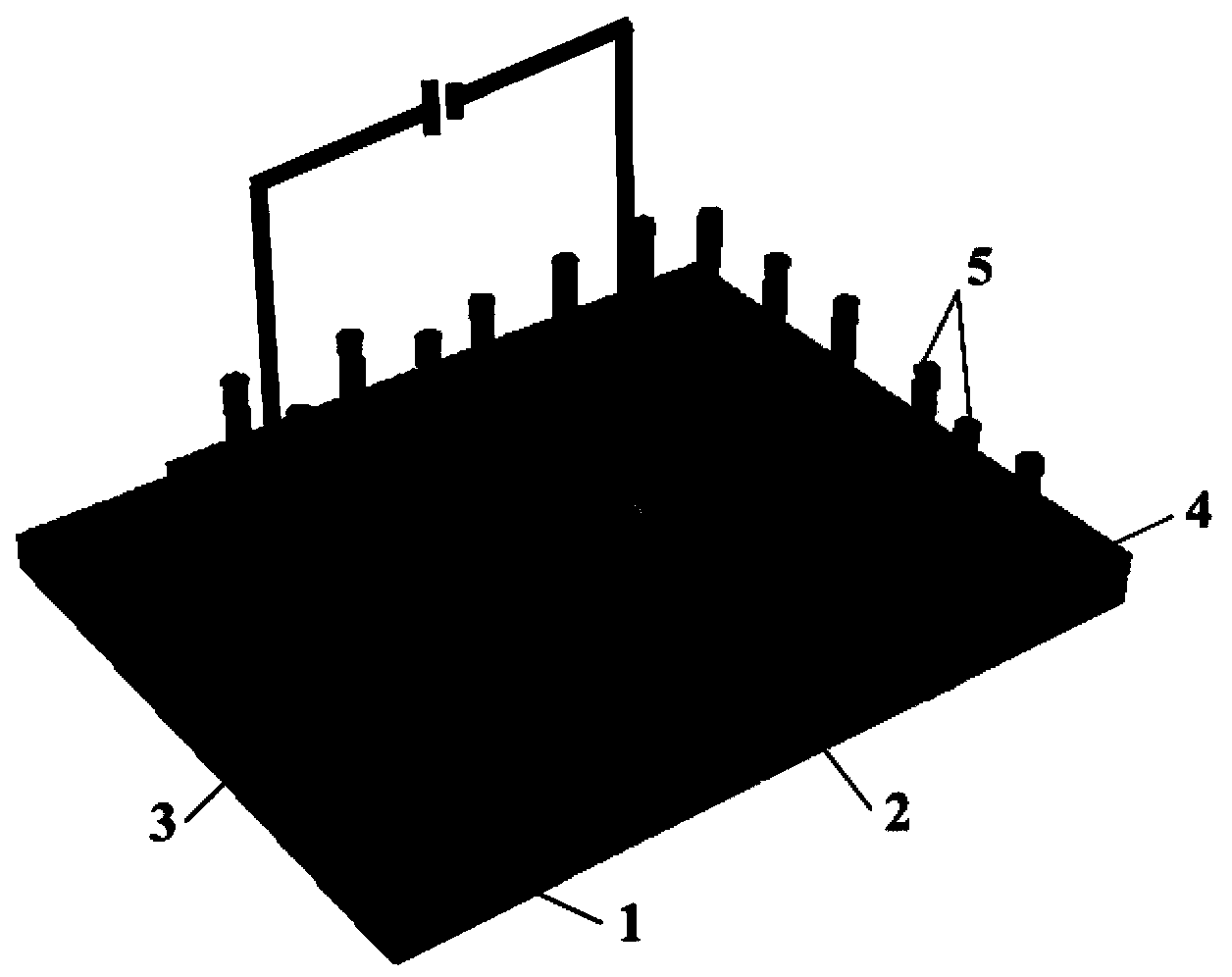

Embodiment 1

[0027] 1) The ITO conductive glass with a size of 9 mm×12 mm was ultrasonically cleaned with acetone, ethanol and isopropanol in sequence, and dried with nitrogen; 2) A layer with a thickness of 200 μm was grown on the ITO conductive glass by magnetron sputtering. nm ZnO thin film, choose ZnO target material with a purity of 99.999%, RF power supply, sputtering rate of 0.018 nm / s; 3) Dot Ag glue near the center of the ZnO thin film and place it at room temperature for 4 h to make it dry. The diameter of the Ag electrode is 1.8 mm; 4) Cover the surface of the Ag electrode with a layer of polydimethylsiloxane PDMS that has been added with a curing agent and placed at room temperature for 45 minutes, and then heated in an oven at 65°C for 40 minutes to make the PDMS electrode protective layer Curing; 5) Put the obtained substrate into a container filled with 0.05 M growth solution (deionized water, zinc nitrate and hexamethylenetetramine) and grow at 95°C for 14 h. After the...

Embodiment 2

[0030] The ultraviolet detector of this embodiment is basically the same as that of Embodiment 1, the difference is that: the thickness of the ZnO film deposited by magnetron sputtering in step 2) of Embodiment 1 is 225 nm in this embodiment; the growth time in step 5) In this example it is 6 h.

[0031]

Embodiment 3

[0033] The ultraviolet detector of this embodiment is basically the same as that of Embodiment 1, the difference lies in: Step 3) of Embodiment 1 In this embodiment, Pt slurry is dotted on the ZnO thin film to make a Pt electrode.

[0034]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com