An anti-interference rapid detection method for exogenously doped sucrose in tea

A detection method and technology for sucrose, applied in the measurement of color/spectral properties, material analysis by observing the effect on chemical indicators, and analysis by causing chemical reactions to occur in materials, etc., can solve the interference color judgment and absorbance measurement, sucrose The components cannot develop normal color, flocculent turbidity and other problems, to avoid severe dependence, low professional level requirements, and simple instruments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

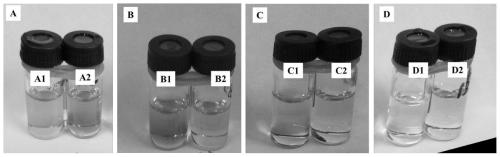

[0038] Comparative experiment on treatment effects of different adsorbents

[0039] 1) Weigh 0.10 g of resorcinol, dissolve it in 100 mL of concentrated hydrochloric acid, and mix it with 100 mL of deionized water to prepare a color reagent;

[0040] 2) Weigh 3.0 g of a green tea sample with 3% sucrose content pre-fried in the laboratory, add 150 ml of boiling water to brew for 5 minutes, drain the tea soup, and use it as the tea soup to be tested.

[0041] 3) Take four 1ml portions of the above tea soup sample and place them in 4 numbered centrifuge tubes. No adsorbent is added to centrifuge tube 1, 30mg activated carbon is added to centrifuge tube 2, and 30mg cross-linked polyvinylpyrrolidone is added to centrifuge tube 3. 4 Add 25mg of cross-linked polyvinylpyrrolidone and 5mg of activated carbon;

[0042] After mixing, heat in a water bath at 50°C for 10 minutes and centrifuge;

[0043] 4) Take 8 transparent glass test tubes of the same specification, 4 of which add 1ml hydrochlori...

Embodiment 2

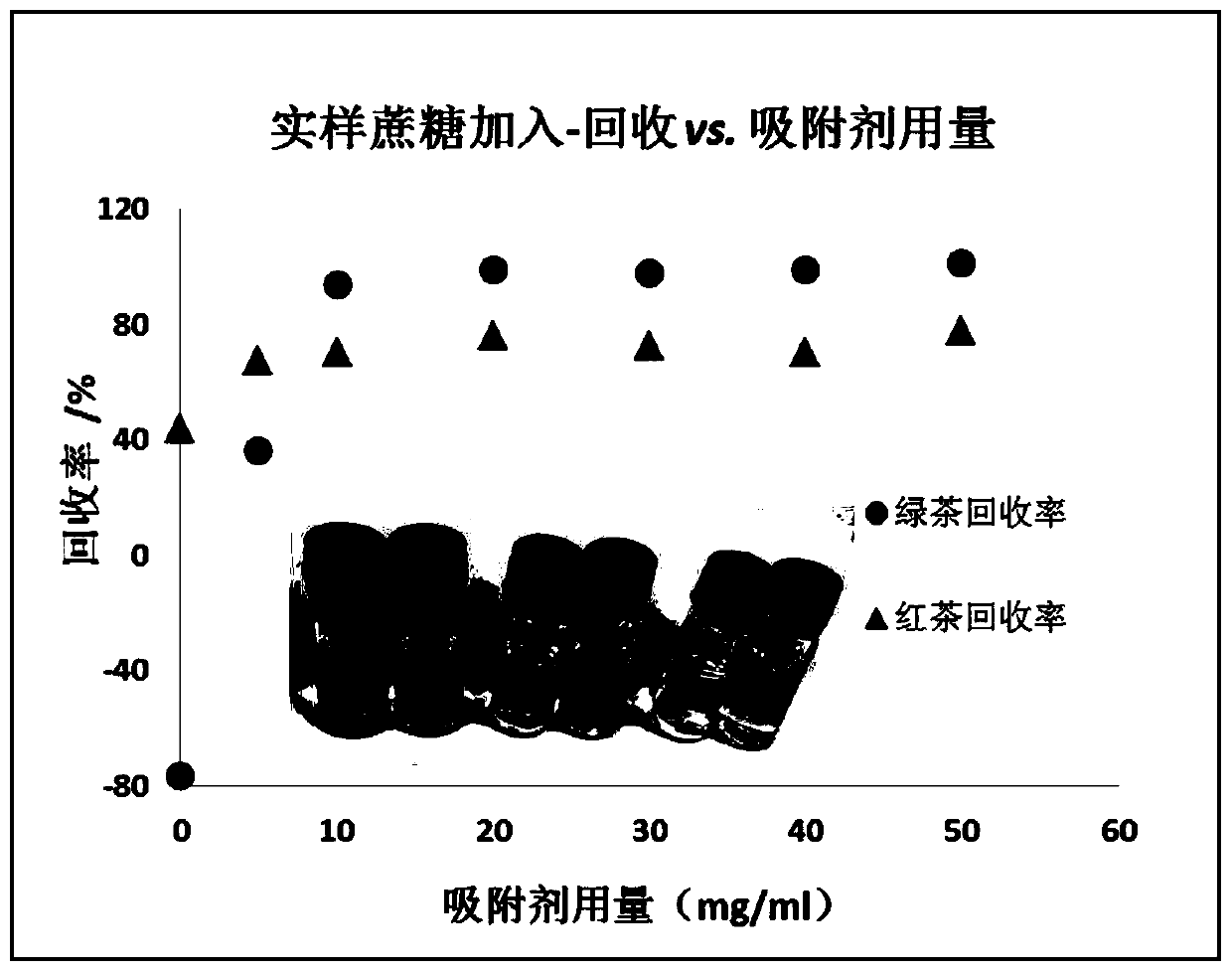

[0046] Example 2. The effect of the amount of adsorbent on the color development of sucrose-containing tea soup samples

[0047] 1) Weigh each 1.0g of black tea and green tea samples added with sucrose during processing and put them in an Erlenmeyer flask, add about 40mL boiling water, and put the Erlenmeyer flask into an ultrasonic processor for ultrasonic extraction for 5 minutes; after filtering out the extract , Add 40 mL of boiling water again, and repeat the above ultrasonic treatment. Wash the respective tea residues twice with deionized water, combine the two ultrasonic extracts of the same tea sample and the tea residue cleaning solution, and dilute the volume to 100 mL after cooling as a tea soup sample.

[0048] 2) Take 7 centrifuge tubes and put 1mL each of the black tea soup samples obtained above, and add adsorbents of different masses in sequence. The adsorbent is a mixture of cross-linked polyvinylpyrrolidone and activated carbon with a mass ratio of 1:0.2. After mi...

Embodiment 3

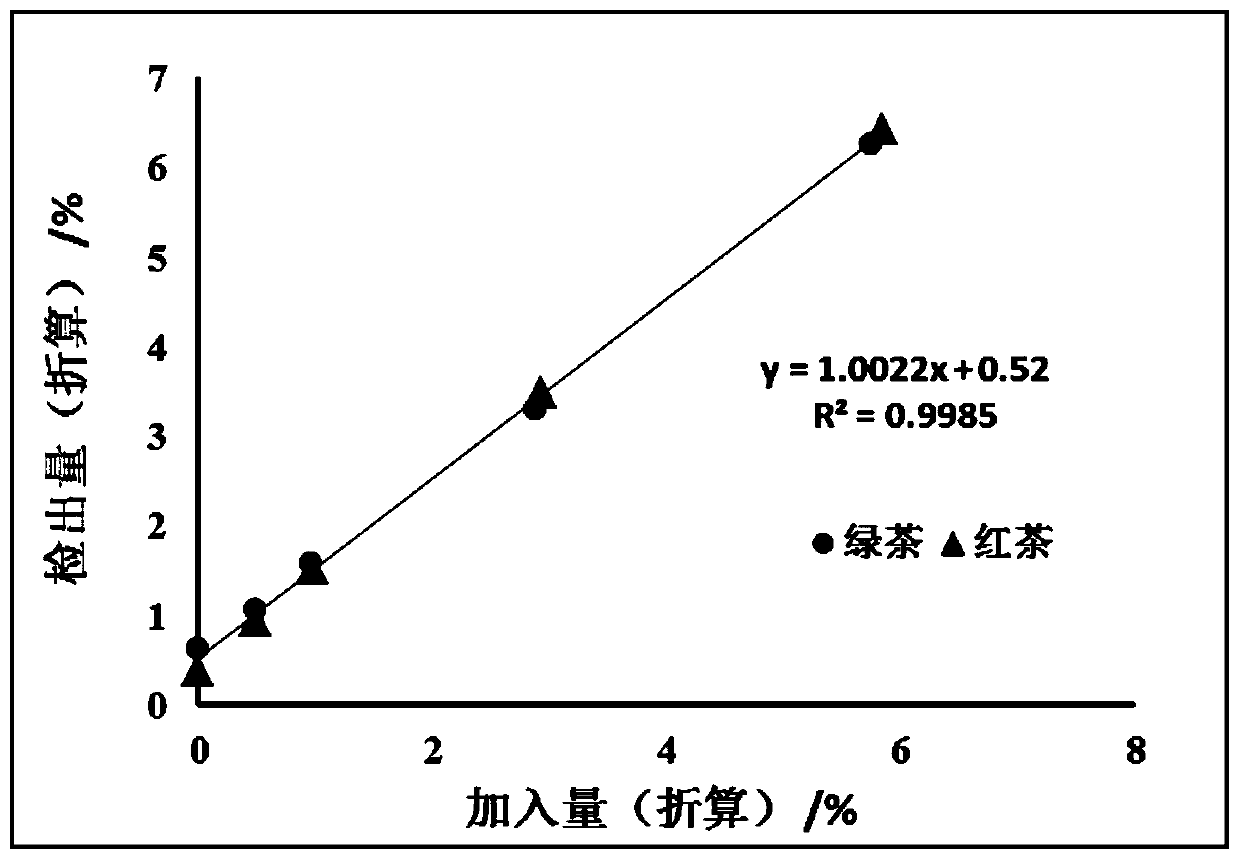

[0054] Example 3. Standard addition recovery experiment

[0055] Reagents and blank tea soup samples of black tea and green tea were prepared according to the conditions of the foregoing Example 2, and a working curve was drawn. In the two tea soup samples obtained, sucrose was added at five concentration levels of 0, 0.05, 0.10, 0.20, 0.30, and 0.60g / L. The adsorbent was the same as in Example 2, and the amount of adsorbent was 30mg / 1mL tea soup sample; and Determine the recovery rate of the detection method. The experimental results showed that at the spiked level of 0.05-0.60g / L, the detection recovery rate of sucrose in black tea soup was 103.4%-117.8%, and the recovery rate of sucrose in green tea soup was 91.9%-100.5%.

[0056] Converting the spiked concentration level in the tea soup to the sucrose content in dry tea and plotting it in Excel, the fitted linear equation between the added sucrose and the detected amount is y=1.022x+0.52(R 2 =0.9985), the specific results are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com