A kind of preparation method of ybco superconducting film for droplet-free microstrip antenna

A technology of microstrip antenna and superconducting film, applied in cable/conductor manufacturing, vacuum evaporation plating, coating, etc., can solve the problem of high droplet rate and achieve the effect of solving droplet and high uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The specific preparation steps of YBCO superconducting film for droplet-free microstrip antenna are as follows:

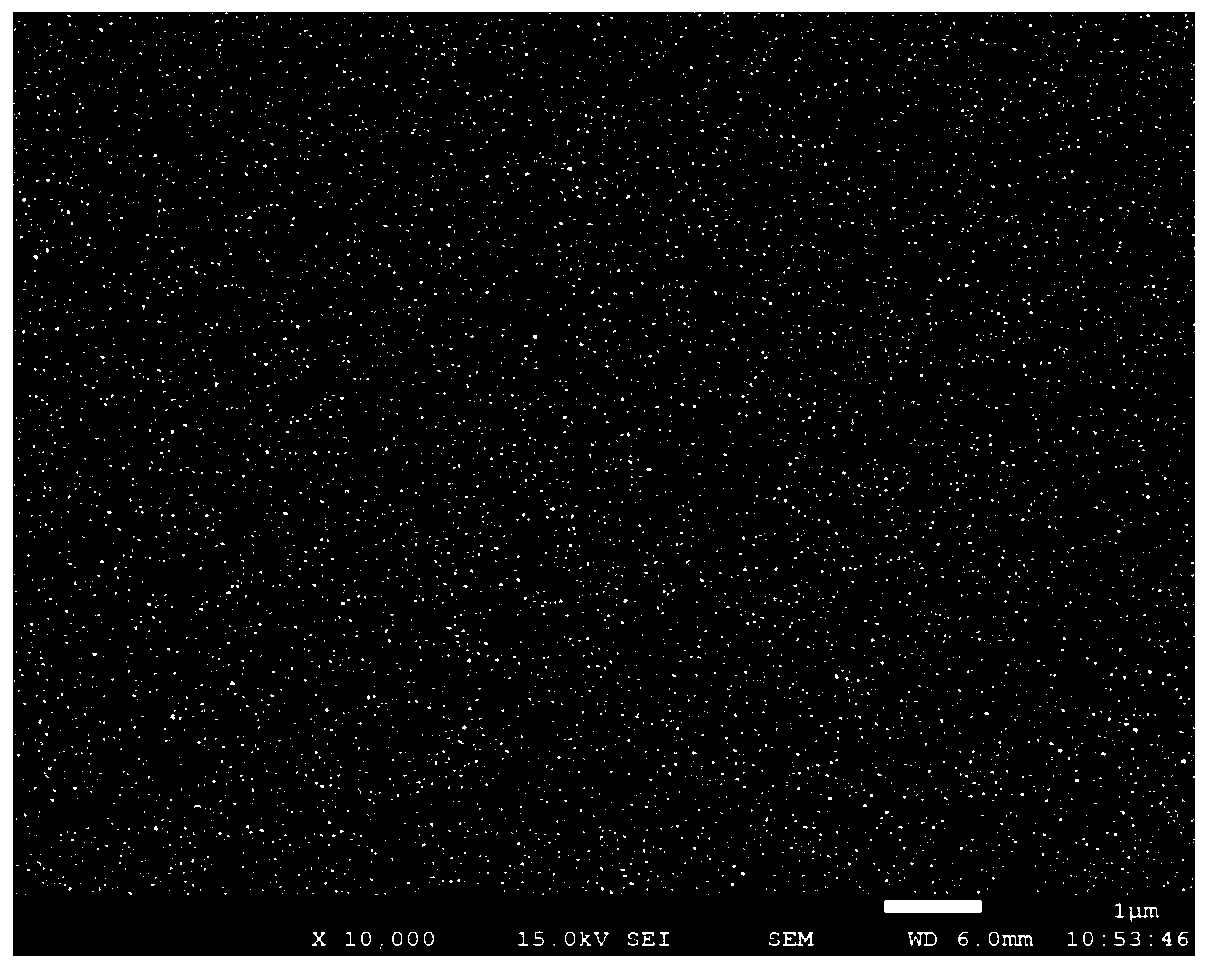

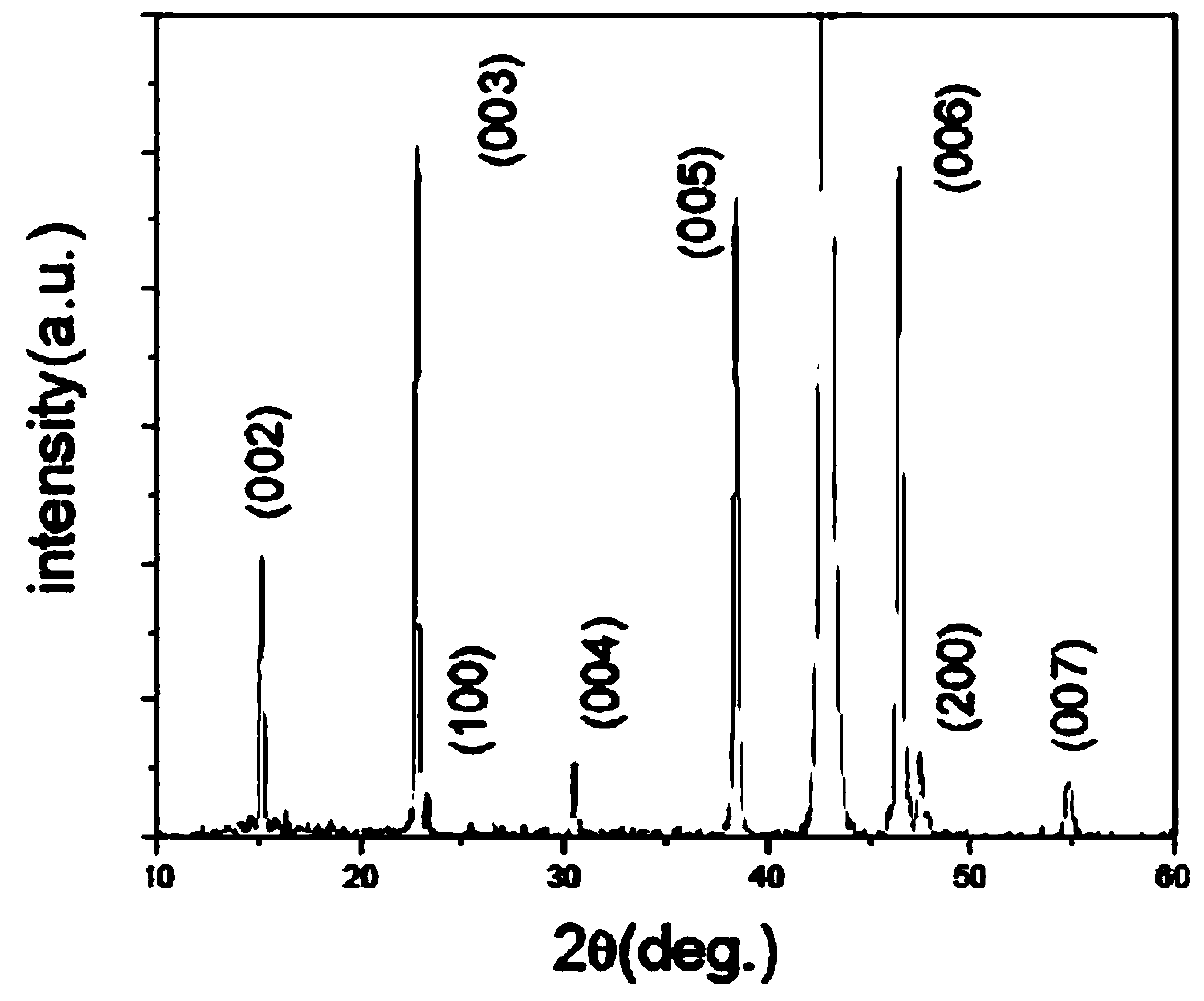

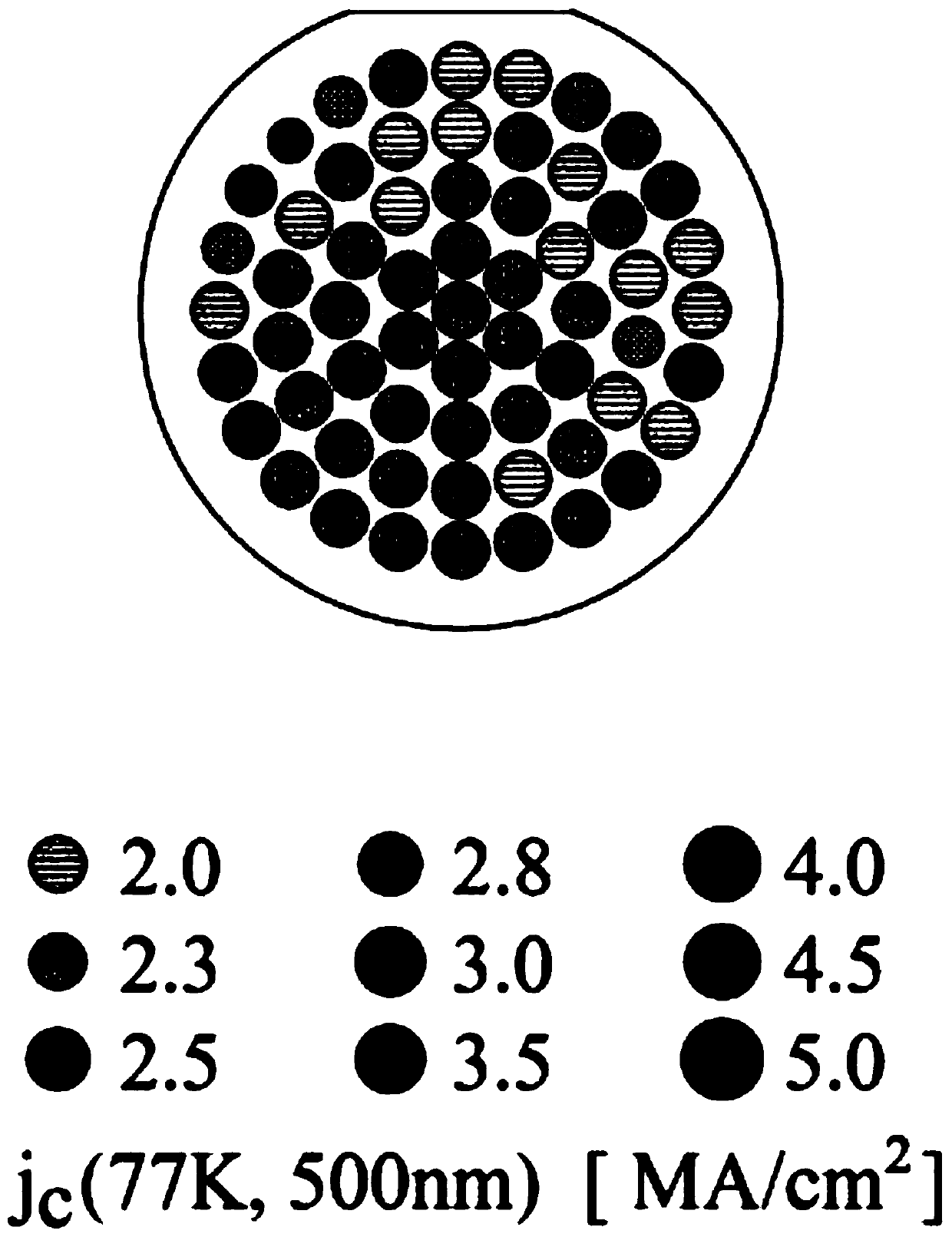

[0026] Step 1. Fill oxygen into the femtosecond pulsed laser system and make the air pressure of oxygen be 15Pa, adjust the distance between the YBCO target material and the single-crystal MgO substrate of (100) crystal orientation to be 2.25cm, and the rotation speed of the single-crystal MgO substrate is set to 5 cycles / min, by adjusting the deflection mirror in the femtosecond pulse laser system, the scanning range of the femtosecond pulse laser on the YBCO target is 1.5cm×1.5cm; A femtosecond pulse laser with a width of 50 fs bombards the YBCO target, and deposits the bombarded material on a single crystal MgO substrate at a temperature of 550 ° C. After 3 hours of deposition, a YBCO deposition layer is obtained on the single crystal MgO substrate;

[0027] Step 2. Place the single crystal MgO substrate loaded with the YBCO deposition layer in an anneali...

Embodiment 2

[0031] The specific preparation steps of YBCO superconducting film for droplet-free microstrip antenna are as follows:

[0032] Step 1. Fill the femtosecond pulsed laser system with oxygen and make the oxygen pressure 20Pa, adjust the distance between the YBCO target and the (100) single crystal LAO substrate to be 2.25cm, and the rotation speed of the single crystal LAO substrate to be 7 cycle / min, by adjusting the deflection mirror in the femtosecond pulse laser system, the scanning range of the femtosecond pulse laser on the YBCO target is 1.5cm×1.5cm; The 120fs femtosecond pulsed laser bombards the YBCO target, and deposits the bombarded material on the single crystal LAO substrate at a temperature of 600°C. After 2 hours of deposition, the YBCO deposition layer is obtained on the single crystal LAO substrate;

[0033] Step 2. Place the single crystal LAO substrate loaded with the YBCO deposition layer in an annealing furnace filled with oxygen, and the oxygen pressure in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com