A method and device for ozone heterogeneous catalytic oxidation of cod in wastewater

A technology for heterogeneous catalysis and oxidation of wastewater, applied in chemical instruments and methods, oxidized water/sewage treatment, molecular sieve catalysts, etc., can solve the problems of low ozone utilization and high operating costs, and reduce ozone usage and operating costs. , the effect of improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

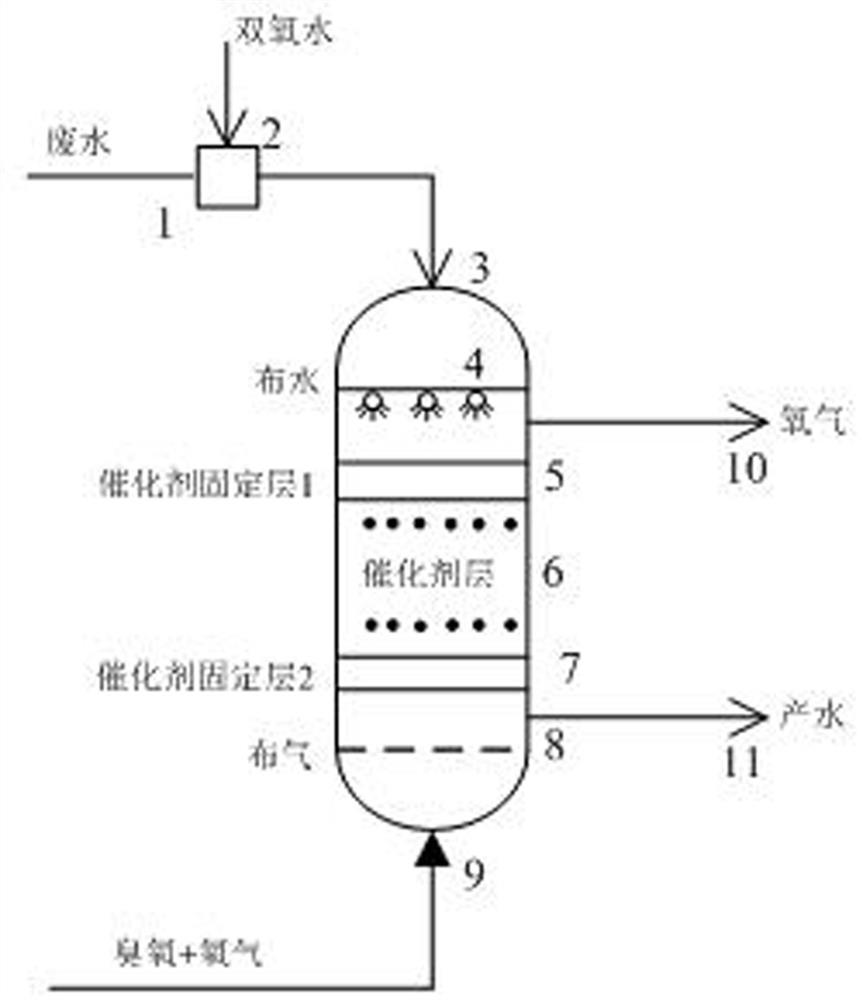

[0041] A device for ozone heterogeneous catalytic oxidation of COD in wastewater (such as figure 1 As shown), it is specifically a waste water oxidation tower. The interior of the tower body consists of water distribution equipment 4, solid catalyst layer and gas distribution equipment 8 from top to bottom; the top of the tower is provided with a mixed liquid inlet 3, which is connected to the waste water inlet Water pipe 1 and hydrogen peroxide water inlet pipe 2; a mixed gas inlet 9 of ozone and oxygen is provided at the bottom of the tower; an oxygen outlet 10 is provided outside the tower wall of the water distribution device 4, and a water production outlet 11 is provided outside the tower wall of the solid catalyst layer.

[0042] The solid catalyst layer includes catalyst fixed layer 15, catalyst layer 6 and catalyst fixed layer 27 from top to bottom.

[0043] Catalyst fixed layer 1 and catalyst fixed layer 2 use pebbles with a particle size of 2 to 15 mm to fix the sol...

Embodiment 2

[0050] A method for ozone heterogeneous catalytic oxidation of COD in wastewater (using the device of Example 1), the steps are:

[0051](1) Wastewater with a COD concentration of 100 mg / L is sent from the waste water inlet pipe 1, and hydrogen peroxide with a mass concentration of hydrogen peroxide of 27.5% is sent from the water inlet pipe 2, and after mixing, enter the water distribution equipment 4 through the mixed solution inlet 3 and distribute them evenly; The mixed gas of ozone and oxygen enters the lower part of the oxidation tower from the inlet 9 of the mixed gas of ozone and oxygen at the bottom of the tower, and after being evenly distributed by the gas distribution device 8, it enters the solid catalyst layer (catalyst fixed layer 1 5, catalyst layer 6 and catalyst fixed layer 2 7) ; Wherein, the active component of the solid catalyst is aluminum with a mass fraction of 15% and iron with a mass fraction of 12%; the molar ratio of ozone to hydrogen peroxide is con...

Embodiment 3

[0055] A method for ozone heterogeneous catalytic oxidation of COD in wastewater (using the device of Example 1), the steps are:

[0056] (1) Wastewater with a COD concentration of 200 mg / L is passed through the waste water inlet pipe 1, and hydrogen peroxide with a mass concentration of hydrogen peroxide of 27.5% is passed through the water inlet pipe 2, and after mixing, enter the water distribution equipment 4 through the mixed solution inlet 3 and distribute them evenly; The mixed gas of ozone and oxygen enters the lower part of the oxidation tower from the inlet 9 of the mixed gas of ozone and oxygen at the bottom of the tower, and after being evenly distributed by the gas distribution device 8, it enters the solid catalyst layer (catalyst fixed layer 1 5, catalyst layer 6 and catalyst fixed layer 2 7) ; Wherein, the active component of the solid catalyst is aluminum with a mass fraction of 15% and manganese with a mass fraction of 12%; the molar ratio of ozone to hydrogen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com