Method for directly preparing nickel-cobalt-aluminum ternary cathode material precursor by using acid leaching solution of laterite nickel ore

A technology of laterite nickel ore and positive electrode materials, which is applied in the field of preparation of lithium battery positive electrode material precursors, and can solve the problems of low actual capacity of nickel-cobalt-manganese ternary positive electrode materials, low nickel substitution, and restrictions on wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

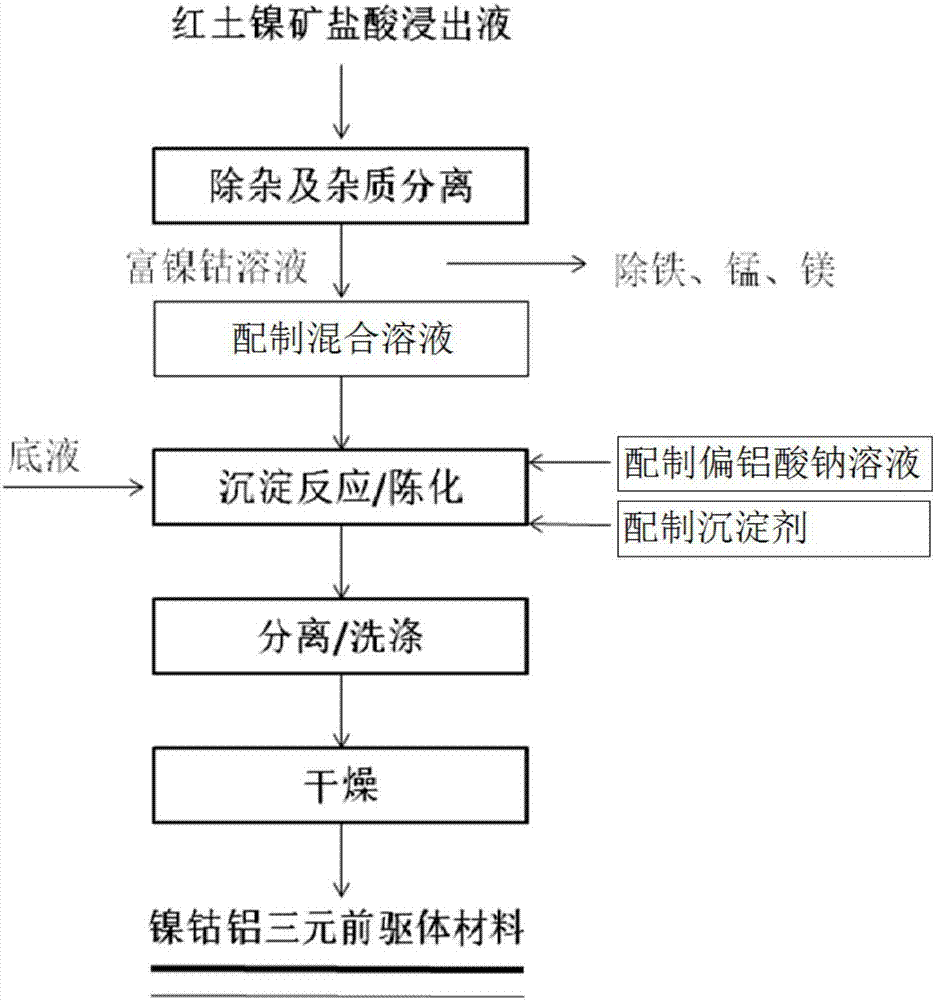

[0113] This embodiment provides a method for preparing a nickel-cobalt-aluminum ternary positive electrode material precursor using the acid leaching solution of laterite nickel ore as a raw material. The specific preparation method is as follows:

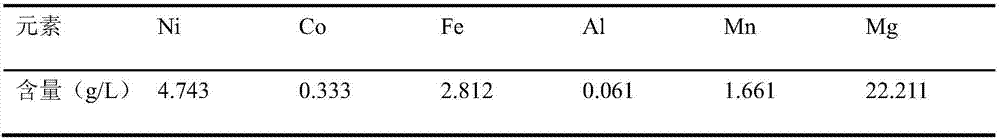

[0114] A. Impurity removal and impurity separation: take 150m 3 For laterite nickel ore hydrochloric acid leaching solution, the content of each element is shown in the table below:

[0115]

[0116] ① Adding 330 kg of magnesia slurry with a mass fraction of 1% drop by drop, controlling the pH to 3.8, separating iron from solid and liquid, and taking the filtrate;

[0117] ②Then add 5wt.% NaOH and 212kg of 8wt% hydrogen peroxide to the above pickling solution, control pH=9.0, separate solid-liquid to take filter cake, add 5wt% dilute sulfuric acid 20m 3 , solid-liquid separation except Mn, Mg, get filtrate;

[0118] 3. add 5wt%NaOH solution in above-mentioned filtrate, control pH=10.5, filter and get filter cake, filter cake q...

Embodiment 2

[0131] This embodiment provides a method for preparing a nickel-cobalt-aluminum ternary positive electrode material precursor using the acid leaching solution of laterite nickel ore as a raw material. The specific preparation method is as follows:

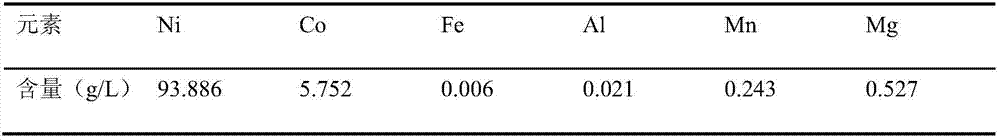

[0132] A. Impurity removal and impurity separation: take 75m 3 For laterite nickel ore hydrochloric acid leaching solution, the content of each element is shown in the table below:

[0133]

[0134] ① Slowly add 248.5 kg of magnesium carbonate slurry with a mass fraction of 2%, control the pH within the range of 4.0, filter to remove iron, and take the filtrate;

[0135] ② Then add 5wt% NaOH and 159kg of 10wt% hydrogen peroxide to the above pickling solution, control the pH=9.5, filter to take the filter cake, add 10wt% dilute nitric acid 10m 3 , solid-liquid separation except Mn, Mg, get filtrate;

[0136] 3. add 5wt% NaOH solution in above-mentioned filtrate, control pH=11, filter and get filter cake, filter cake quality is ...

Embodiment 3

[0147] This embodiment provides a method for preparing a nickel-cobalt-aluminum ternary positive electrode material precursor using the acid leaching solution of laterite nickel ore as a raw material. The specific preparation method is as follows:

[0148] A. Impurity removal and impurity separation: take 50m 3 The content of each element in the laterite nickel ore hydrochloric acid leaching solution is as follows:

[0149]

[0150] 1. Add 101.5kg of magnesium hydroxide slurry with a mass fraction of 3% dropwise, control the pH within the range of 4.2, filter and remove iron, and get the filtrate;

[0151] ② Then add 5wt% NaOH and 89kg of 15wt% hydrogen peroxide to the above pickling solution, control the pH=10.0, filter to take the filter cake, add 5wt% dilute hydrochloric acid 5m 3 , solid-liquid separation except Mn, Mg, get filtrate;

[0152] 3. add 5wt% NaOH solution in above-mentioned filtrate, control pH=11.5, filter and get filter cake, filter cake quality is (dry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com