Titanium dioxide doped carbon nitride, and preparation method and application thereof

A technology of titanium dioxide and carbon nitride, applied in electrical components, non-aqueous electrolyte batteries, circuits, etc., can solve the problems of low coulombic efficiency and poor cycle stability of lithium-sulfur batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

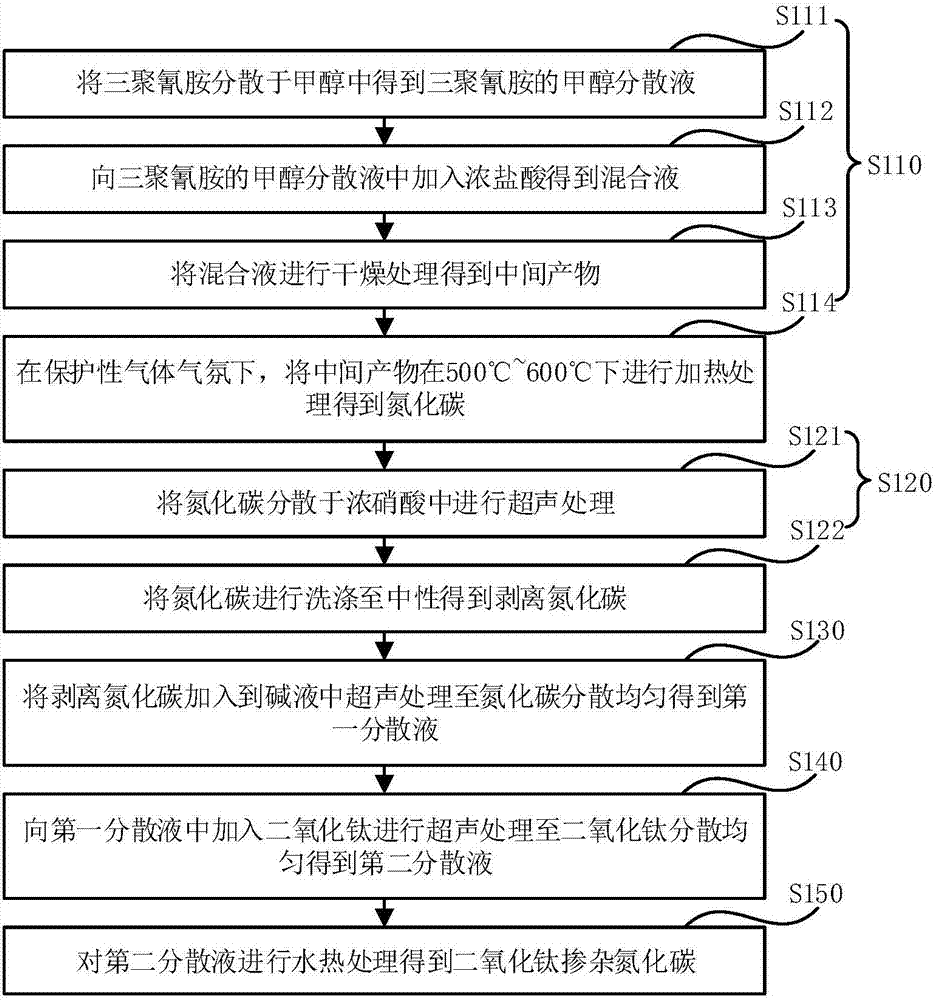

[0037] see figure 1 , the preparation method of titanium dioxide doped carbon nitride of an embodiment, comprises the following steps:

[0038] S110, preparing carbon nitride.

[0039] In one of the embodiments, the step of preparing carbon nitride specifically includes the following steps:

[0040] S111. Dispersing melamine in methanol to obtain a methanol dispersion of melamine.

[0041] In one embodiment, the mass ratio of melamine to methanol is 1:5˜1:20.

[0042] In one embodiment, the melamine is added into the methanol and then stirred, the time of the stirring is 1h-4h, and the rotation speed of the stirring is 80r / min-200r / min.

[0043] S112, adding concentrated hydrochloric acid to the methanol dispersion of melamine to obtain a mixed solution.

[0044] In one embodiment, the mass concentration of the concentrated hydrochloric acid is 20%-37%.

[0045] In one embodiment, the dosage ratio of melamine to concentrated hydrochloric acid is 1g:1mL˜1g:20mL.

[0046] ...

Embodiment 1

[0113] Disperse 5 g of melamine in 75 g of methanol and stir for 1 h to obtain a methanol dispersion of melamine, then add 5 mL of concentrated hydrochloric acid with a mass concentration of 37% to the methanol dispersion of melamine, and continue stirring for 1 h to obtain a mixed solution. The mixed solution was placed in a vacuum drying oven, methanol and the like were evaporated to dryness to obtain an intermediate product, and then the intermediate product was heat-treated at 600° C. under a nitrogen atmosphere to obtain carbon nitride. Add 1g of carbon nitride into 50mL of concentrated nitric acid with a mass concentration of 95%, and perform ultrasonic treatment, wherein the power of ultrasonic treatment is 100W, and the time of ultrasonic treatment is 15h; the carbon nitride is washed alternately with water and alcohol until Neutral to get stripped carbon nitride, the specific surface area of stripped carbon nitride is 160m 2 / g.

[0114] Add 0.2 g of stripped carbo...

Embodiment 2

[0117] Disperse 10 g of melamine in 100 g of methanol and stir for 1 h to obtain a methanol dispersion of melamine, then add 200 mL of concentrated hydrochloric acid with a mass concentration of 20% to the methanol dispersion of melamine, and continue stirring for 4 h to obtain a mixed solution. The mixed solution was placed in a vacuum drying oven, methanol, etc. were evaporated to dryness to obtain an intermediate product, and then the intermediate product was heat-treated at 550° C. under a nitrogen atmosphere to obtain a carbon nitride primary product. Add 1g of carbon nitride primary product into 50mL of concentrated nitric acid with a mass concentration of 95%, and perform ultrasonic treatment, wherein the power of ultrasonic treatment is 100W, and the time of ultrasonic treatment is 10h; The product is washed to neutrality to obtain carbon nitride, and the specific surface area of carbon nitride is 180m 2 / g.

[0118] Add 0.2 g of stripped carbon nitride to 120 mL of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com