Chocolate wrapping paper

A technology for wrapping paper and chocolate, which is applied in wrapping paper, wrapping paper, packaging, etc., and can solve problems such as high cost, poor moisture resistance, and inconvenient portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

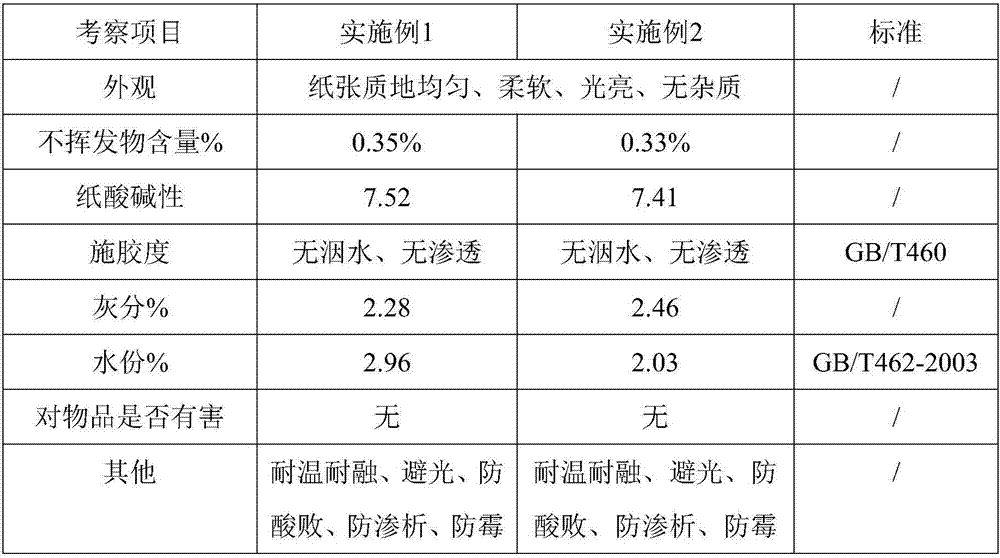

Examples

Embodiment 1

[0021] A Chocolate Wrapper:

[0022] It is made from the following raw material components in parts by weight:

[0023] 37 parts of pulp, 5 parts of ultra-low density polyethylene, 15 parts of palm oil, 15 parts of rice bran wax, 2 parts of sodium stearate lactate, 3 parts of monoglyceride laurate, 5.5 parts of food coloring, 6 parts of complex group nano zinc oxide particles 7 parts of polyethylene glycol, 4 parts of modified bentonite, 2.5 parts of gelatin, 4.5 parts of ethanol, 6.5 parts of hydrogenated lanolin, 7.5 parts of emulsifier, 5.5 parts of carrageenan, 6 parts of polyvinyl alcohol, mucopolysaccharide 6.5 parts, 10 parts of deionized water.

[0024] The preparation method of the composite group nano-zinc oxide particles is as follows: first, prepare and purify 100nm zinc oxide nanoparticles to obtain a light blue transparent ethanol solution of inorganic zinc oxide nanoparticles, and place the ethanol solution of inorganic zinc oxide nanoparticles in 500ml reagent...

Embodiment 2

[0034] A Chocolate Wrapper:

[0035] It is made from the following raw material components in parts by weight:

[0036] 34 parts of pulp, 6 parts of ultra-low density polyethylene, 16 parts of palm oil, 15 parts of rice bran wax, 4.5 parts of sodium stearate lactate, 3.5 parts of monoglyceride laurate, 5.5 parts of food coloring, 7 parts of complex group nano zinc oxide particles 6 parts of polyethylene glycol, 2 parts of modified bentonite, 2.5 parts of gelatin, 10 parts of ethanol, 6 parts of hydrogenated lanolin, 7.5 parts of emulsifier, 6 parts of carrageenan, 9 parts of polyvinyl alcohol, mucopolysaccharide 11 parts, 10 parts of deionized water.

[0037] The preparation method of the composite group nano-zinc oxide particles is as follows: first, prepare and purify 100nm zinc oxide nanoparticles to obtain a light blue transparent ethanol solution of inorganic zinc oxide nanoparticles, and place the ethanol solution of inorganic zinc oxide nanoparticles in 500ml reagent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com