Preparation method for para-aminophenol ordered mesoporous carbon catalyst

A p-aminophenol and catalyst technology, which is applied in the field of nano-catalyst material preparation, can solve the problems of complex and lengthy reaction process, poor recycling performance, and stability to be improved, and achieve cheap and easy-to-obtain raw materials, developed specific surface area, and abundant raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

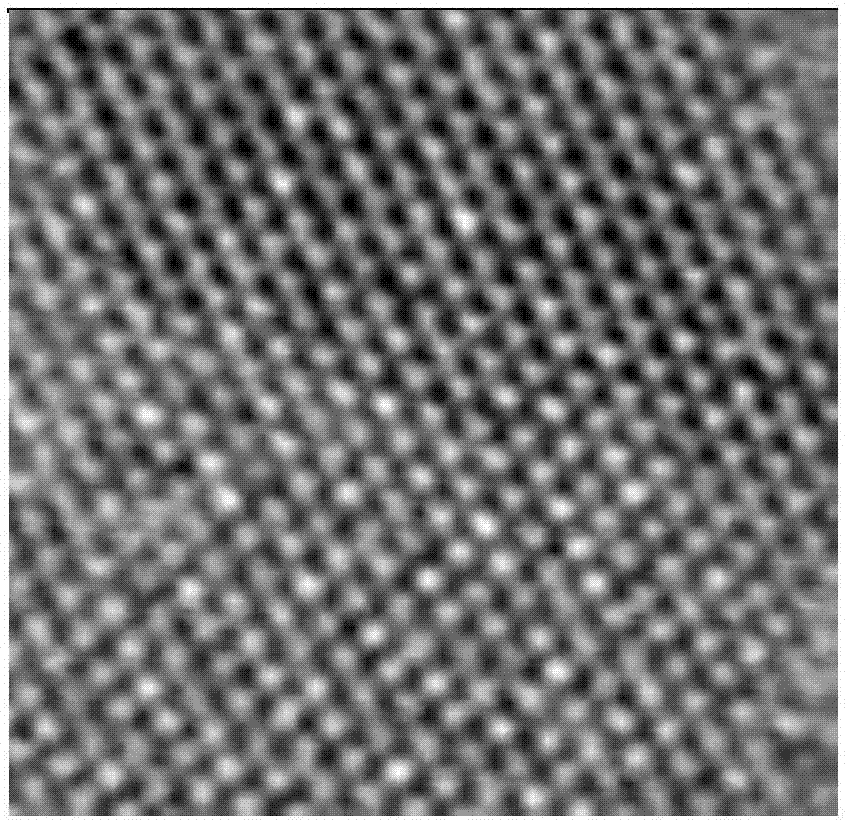

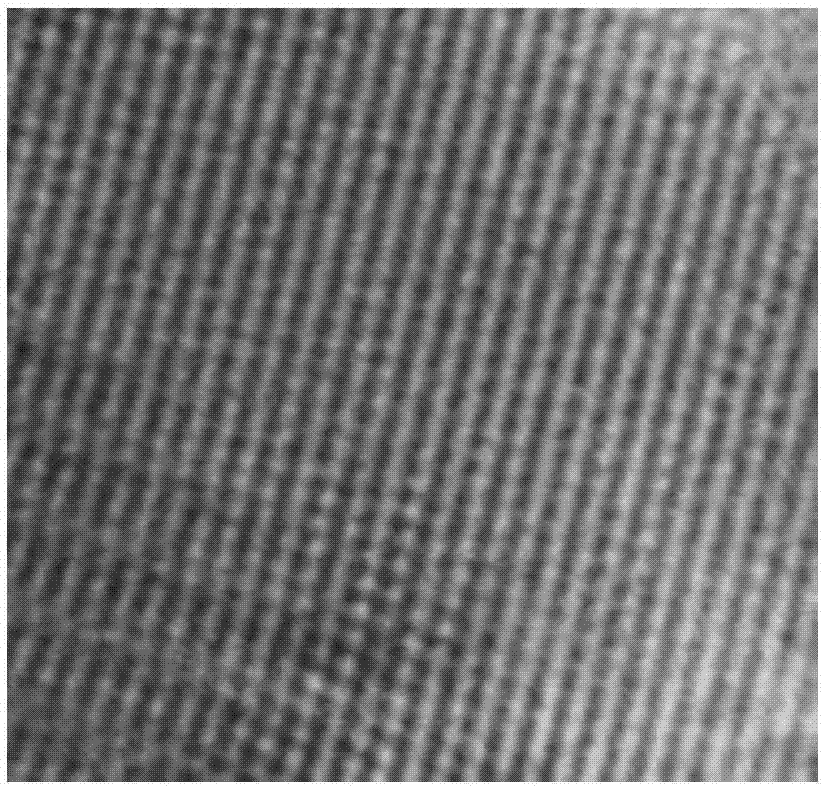

Image

Examples

Embodiment 1

[0022] Using chitosan as raw material, weigh 10g of chitosan and put it into a polytetrafluoroethylene-lined reaction kettle with a volume of 100ml to ensure that the solution volume to kettle volume ratio is 5:10, select cobalt oxide as the doping source, and cobalt oxide The mass ratio of surfactant P123 to chitosan is 1:10. After the surfactant P123 is dissolved, the mass ratio of surfactant P123 to chitosan is guaranteed to be 3:20. After the three are mixed evenly, the reaction kettle is placed in a box-type incubator and heated to the target temperature. 190°C, keep the temperature constant for 8 hours, cool down to room temperature, filter to obtain a dark brown solid, and then wash with deionized water and absolute ethanol until the filtrate is colorless, then dry and grind. The cobalt-doped carbon-based catalyst precursor obtained above was put into a tubular calciner, and carbonized at 850 °C for 2 h under the protection of nitrogen atmosphere to obtain a cobalt-doped...

Embodiment 2

[0025] Take chitosan as raw material, take 7g chitosan and put it into a polytetrafluoroethylene-lined reaction kettle with a volume of 100ml, ensure that the solution volume and kettle volume ratio are 7:10, and choose ferric iron tetroxide as a doping source, Its mass ratio with chitosan is 3:20, after the surfactant F127 and P123 are dissolved, ensure that the mass ratio of the mixture to chitosan is 3:20, after the three are mixed evenly, the reaction kettle is put into a box-type incubator, and the temperature rises. To the target temperature of 220°C, keep the temperature for 6 hours, cool down to room temperature, filter to obtain a dark brown solid, and then wash with deionized water and absolute ethanol until the filtrate is colorless, then dry and grind. The iron-doped carbon-based catalyst precursor obtained above was put into a tubular calciner, and carbonized at 950 °C for 1 h under the protection of nitrogen atmosphere to obtain a cobalt-doped carbon catalyst with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com