Porous SiCO-based nitric oxide sensor

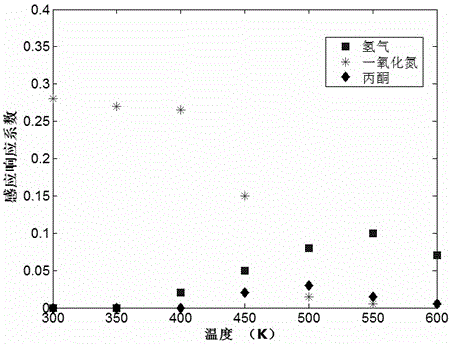

A nitric oxide and sensor technology, applied in the field of sensors, can solve the problems that the detection process is easily interfered by other gases, high working temperature, and high preparation cost, and achieve improved gas sensing performance and interface bonding strength, low temperature components, and high sensitivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

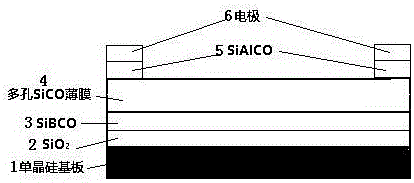

[0025] Example. A porous SiCO-based nitric oxide sensor constituted as figure 1 As shown, it includes a single crystal silicon substrate 1, and the single crystal silicon substrate 1 is sequentially provided with SiO 2 The thin film layer 2, the SiBCO thin film layer 3 and the SiCO thin film layer 4, the SiCO thin film layer 4 is provided with an electrode 6 through the SiAlCO thin film layer 5. The SiO 2 Thicknesses of the thin film layer 2 and the SiBCO thin film layer 3 are both 95-105 nm (100 nm). The thickness of the SiAlCO thin film layer 5 is 95-105 nm (100 nm). The SiCO thin film layer 4 has a thickness of 800 nm.

[0026] Porous SiCO-based nitric oxide sensor, the preparation method is carried out according to the following steps:

[0027] ①Use acetone to ultrasonically clean the mono...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com