A longitudinal gradient short fiber piezoelectric composite material and its preparation method

A piezoelectric composite material and piezoelectric composite technology, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, device material selection, etc., can solve problems such as the polarization dead zone of piezoelectric fibers, and achieve accurate and reliable structural dimensions. control, low requirements, simple and easy process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

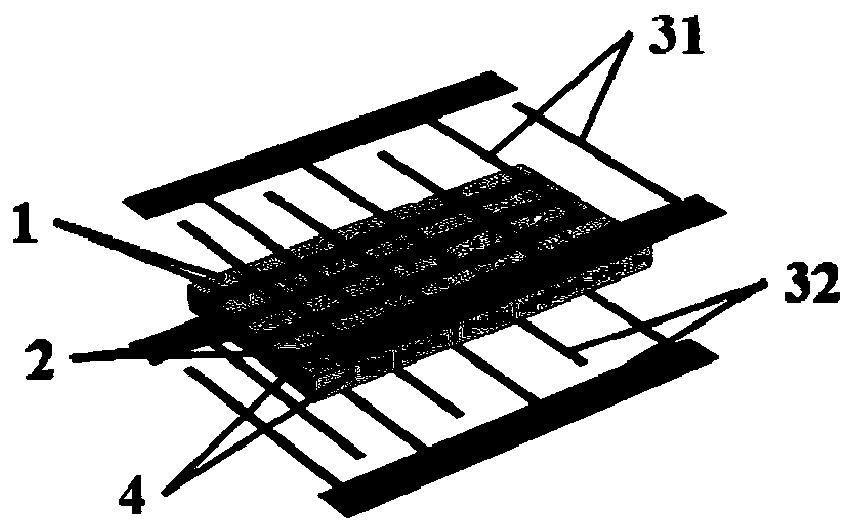

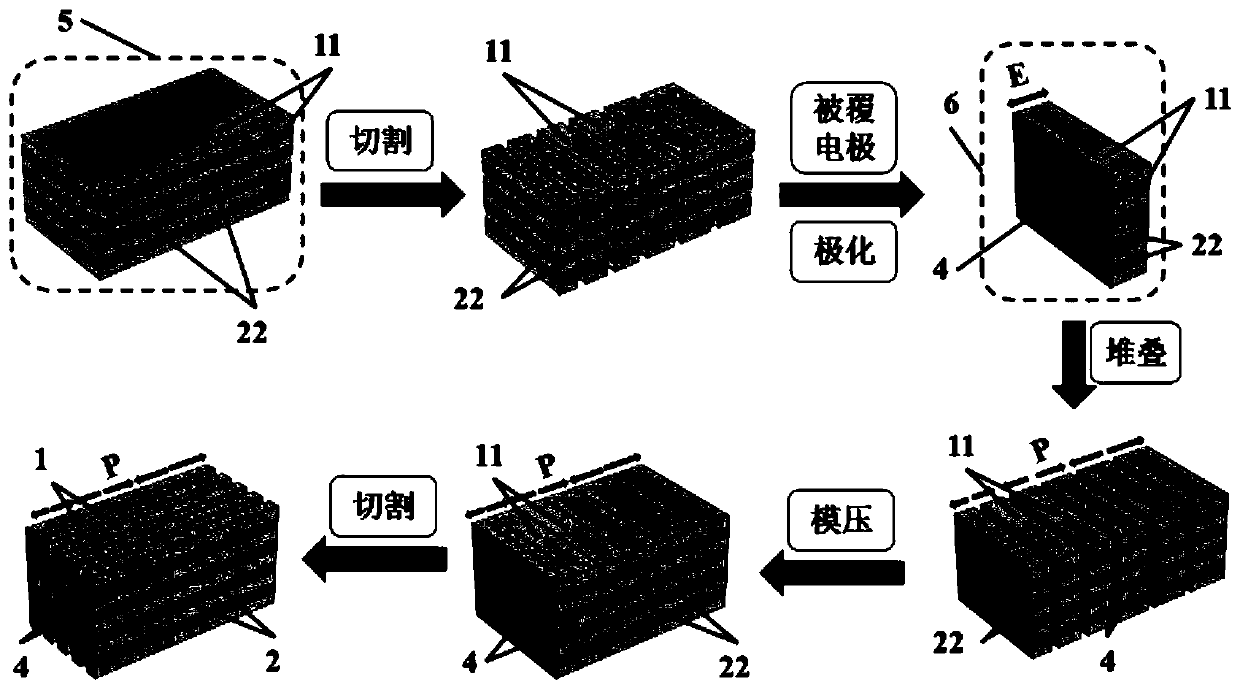

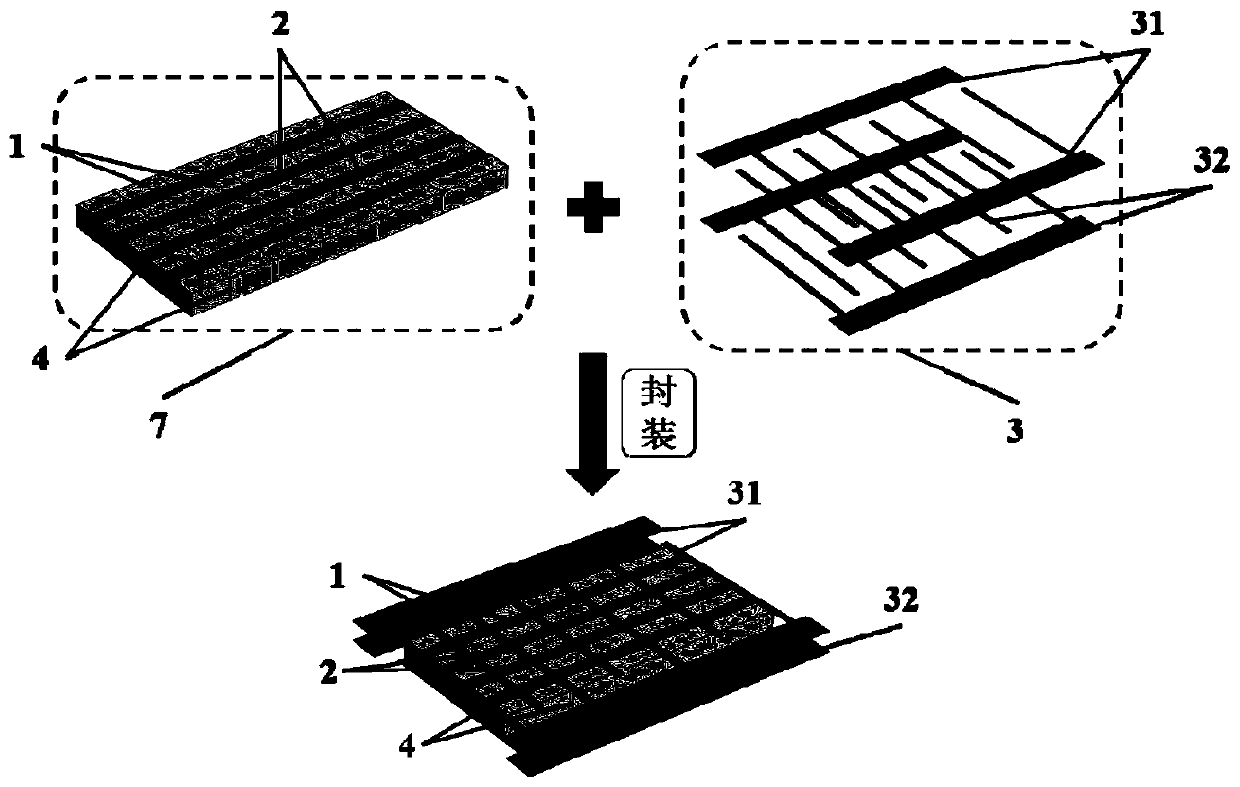

[0037] Please refer to figure 2 and image 3 , the embodiment of the present invention also provides a method for preparing a longitudinal gradient short fiber piezoelectric composite material, comprising the following steps:

[0038] S1. A piezoelectric composite structure 5 is obtained by alternately stacking multiple piezoelectric thin layers 11 and multiple polymer thin layers 22 , and each polymer thin layer 22 is connected to a piezoelectric thin layer 11 on both sides.

[0039] For the convenience of subsequent description, the length direction along the plane where the piezoelectric thin layer 11 is located is defined as the first direction, and the width direction along the plane where the piezoelectric thin layer 11 is located is defined as the second direction.

[0040] Specifically, a plurality of piezoelectric thin layers 11 and a plurality of polymer thin layers 22 are spliced alternately, and the piezoelectric thin layers 11 are located on the top and bottom...

Embodiment 1

[0053] This embodiment provides a method for preparing a longitudinally gradient short fiber piezoelectric composite material. PZT is used as the piezoelectric phase and epoxy resin is used as the polymer phase. The method of the present invention is used to prepare the longitudinally gradient short fiber reinforced piezoelectric composite material. The specific process as follows:

[0054] 1. Using PZT ceramics and epoxy resin as raw materials, the lamination-cutting method is used to prepare such as figure 2 The piezoelectric composite structure 5 shown in the above, wherein the number of piezoelectric thin layers 11 is 9, and the thickness is 0.3 mm; the number of polymer thin layers 22 is 8, and the thickness is 0.2 mm; the thickness of the piezoelectric composite structure 5 is The sum of the thicknesses of the electric thin layer 11 and the polymer thin layer 22 is 4.3 mm; the length and width of the piezoelectric fiber composite structure 5 and the piezoelectric thin l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com