Preparation method of rare earth-doped fluoride up-conversion luminescent nano dispersion

A nano-dispersion and rare earth doping technology, which is applied in the field of materials and photonics, and chemical industry, can solve the problems of difficult control of sample shape, sensitivity to air, high synthesis cost, etc., and achieve good up-conversion luminescence performance and small particle size , the effect of narrow particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

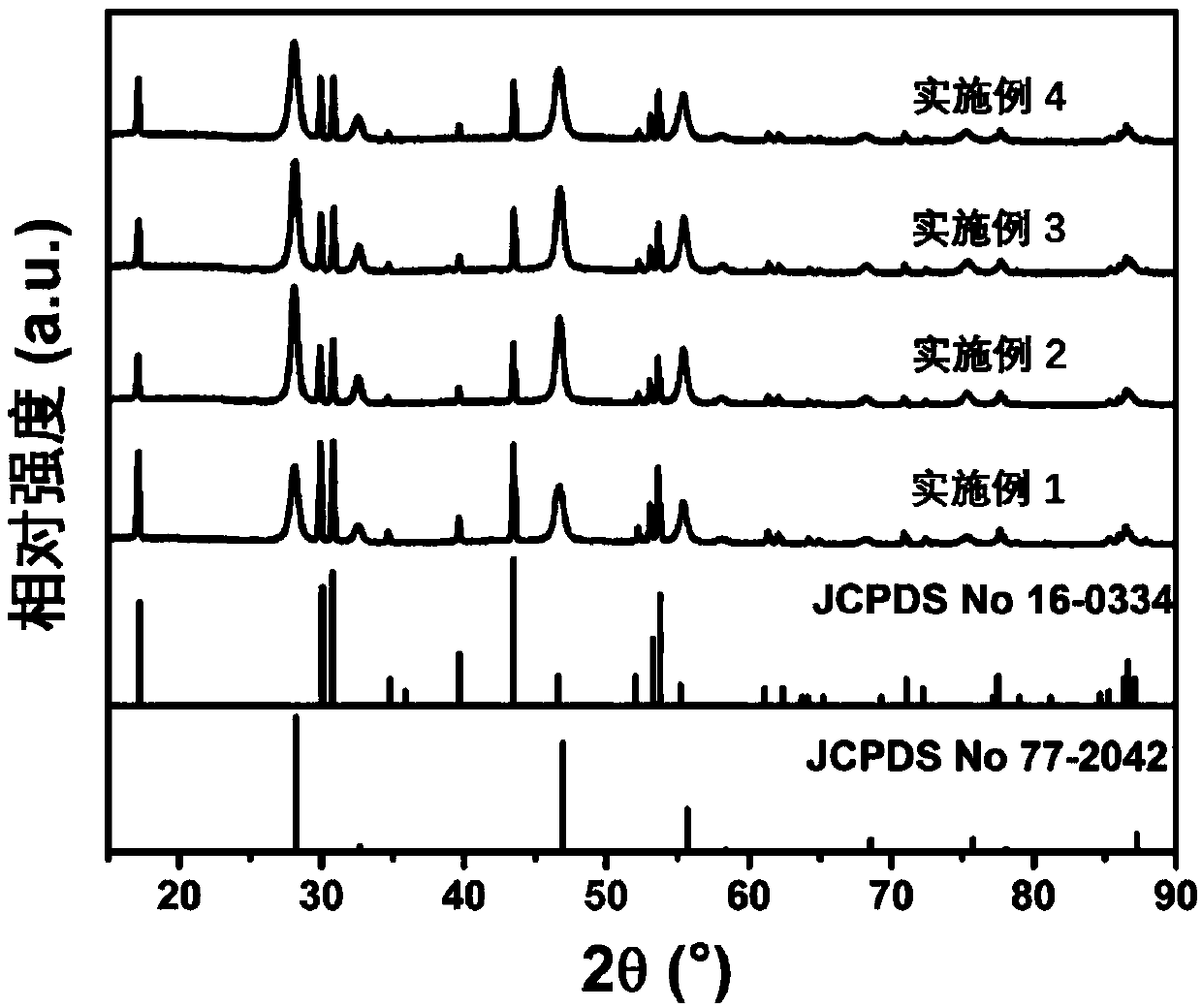

Embodiment 1

[0031] Weigh 2.4g of sodium hydroxide solid and dissolve it in 6mL of deionized water. After completely dissolving, mix the solution with 40mL of oleic acid and 40mL of absolute ethanol as solution A; measure erbium chloride, ytterbium chloride and chlorine 24.8mg, 223.2mg and 776.8mg of yttrium oxide solids were dissolved in 22mL of deionized water as solution B; 16mL of quantitatively prepared ammonium fluoride solution was taken as solution C. Adjust the rotation speed of the external circulation type high gravity rotating packed bed to 1000rpm, pass the A solution into the external circulation type high gravity rotating packed bed through the peristaltic pump, and pass the B solution and the C solution from another feed port through the peristaltic The pump is passed into the external circulation type high gravity rotary packed bed, and the feed flow rate of A solution and B and C solutions is set to 3:1. After all the raw material solutions are passed into the external cir...

Embodiment 2

[0033] Weigh 2.4g of sodium hydroxide solid and dissolve it in 6mL of deionized water. After completely dissolving, mix the solution with 40mL of oleic acid and 40mL of absolute ethanol as solution A; measure erbium chloride, ytterbium chloride and chlorine 24.8mg, 223.2mg and 776.8mg of yttrium oxide solids were dissolved in 22mL of deionized water as solution B; 16mL of quantitatively prepared ammonium fluoride solution was taken as solution C. Adjust the rotation speed of the external circulation type high gravity rotating packed bed to 1500rpm, pass the A solution into the external circulation type high gravity rotating packed bed through the peristaltic pump, and pass the B solution and the C solution from another feed port through the peristaltic The pump is passed into the external circulation type high gravity rotary packed bed, and the feed flow rate of A solution and B and C solutions is set to 3:1. After all the raw material solutions are passed into the external cir...

Embodiment 3

[0035]Weigh 2.4g of sodium hydroxide solid and dissolve it in 6mL of deionized water. After completely dissolving, mix the solution with 40mL of oleic acid and 40mL of absolute ethanol as solution A; measure erbium chloride, ytterbium chloride and chlorine 24.8mg, 223.2mg and 776.8mg of yttrium oxide solids were dissolved in 22mL of deionized water as solution B; 16mL of quantitatively prepared ammonium fluoride solution was taken as solution C. Adjust the rotation speed of the external circulation type high gravity rotating packed bed to 2000rpm, pass the A solution into the external circulation type high gravity rotating packed bed through the peristaltic pump, and pass the B solution and the C solution from another feed port through the peristaltic The pump is passed into the external circulation type high gravity rotary packed bed, and the feed flow rate of A solution and B and C solutions is set to 3:1. After all the raw material solutions are passed into the external circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com