Polyimide film, and preparation method and application thereof

A polyimide film, polyimide technology, used in chemical instruments and methods, layered products, metal layered products, etc., can solve the flexibility or life limit of circuit boards, polyimide and copper The problems of poor foil adhesion and large difference in linear expansion coefficients can achieve the effects of excellent adhesion, excellent flexibility, and excellent film-forming properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A kind of polyimide film, its preparation method comprises the steps:

[0043] 1) Synthesis of polyamic acid (PAA) solution: Carry out according to the molar ratio of BTDA:ODA:DAPBI=5:1:4, first add two kinds of diamine monomers ODA and DAPBI with a molar ratio of 1:4 into the metered In DMAc, make the total solid content 15%, then mechanically stir under the protection of nitrogen, then add BTDA which is equimolar to the total amount of the two diamines in batches, and make it continue to react for 5 hours below 25 ° C in a nitrogen atmosphere to obtain Viscous polyamic acid solution. The polyamic acid solution was sealed and placed in the refrigerator for use, and its viscosity was measured to be 5.3 Pa·s after 24 hours.

[0044] 2) Preparation of polyimide film: cast the PAA solution prepared in step 1) on a clean glass plate to form a film, keep it in a blast oven at 60°C for 30min, at 100°C for 30min, and at 150°C for 30min, then Continue in the vacuum oven, keep...

Embodiment 2

[0053] A polyimide copper clad laminate, such as image 3 As shown, it includes a copper foil layer and a polyimide layer located on the copper foil layer, wherein the thickness of the copper foil layer is 13 μm, and the thickness of the polyimide layer is 20 μm; its preparation includes the following steps:

[0054] The PAA solution prepared in Example 1 was spin-coated on the copper foil, and then the thermal imidization process was completed using the same thermal imidization process as in Example 1 to obtain a polyimide copper-clad laminate.

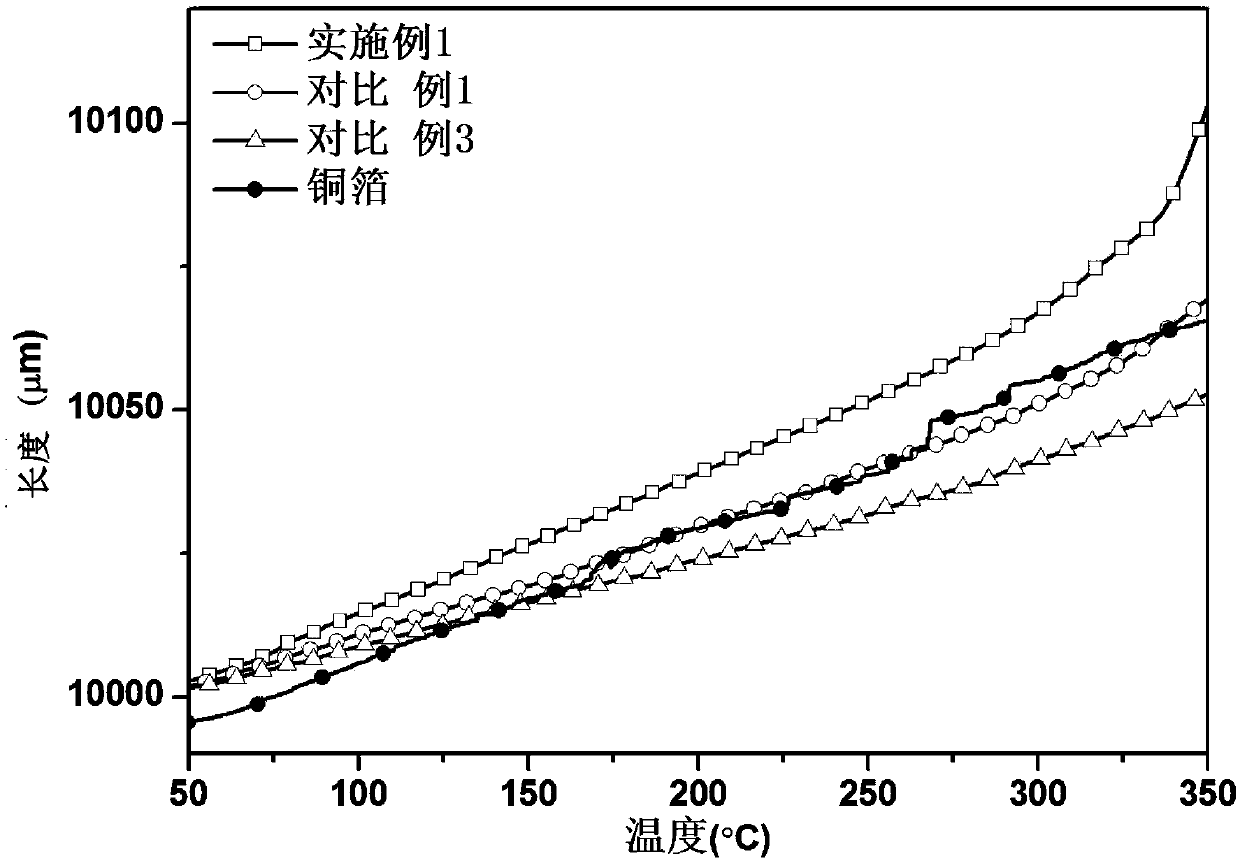

[0055] The polyimide copper-clad laminate in this embodiment has very good flatness, and the polyimide layer and the copper foil layer have very good adhesion performance, see FIG. 2(b) and FIG. 2(c). Take a polyimide copper-clad laminate with a width of 0.5cm and a length of 5cm to conduct a peel performance test. The curve is as follows Figure 4 As shown, the warpage of the copper clad laminate is 3.0 mm, and the T-peel strength ...

Embodiment 3

[0057] A kind of polyimide film, its preparation method comprises the steps:

[0058] 1) Synthesis of polyamic acid solution: Carry out according to the molar ratio of BTDA:ODA:DAPBI=4:1:3, firstly add ODA and DAPBI two diamine monomers with a molar ratio of 1:3 into the metered DMAc, Make the total solid content 15%, then mechanically stir under the protection of nitrogen, then add BTDA which is equimolar to the total amount of the two diamines in batches, and continue to react for 5 hours under the nitrogen atmosphere below 25°C to obtain viscous Polyamic acid solution. The polyamic acid solution was sealed and placed in a refrigerator for use, and its viscosity was measured to be 5.0 Pa·s after 24 hours.

[0059] 2) Preparation of polyimide film: cast the PAA solution prepared in step 1) on a clean glass plate to form a film, keep it in a blast oven at 60°C for 30min, at 100°C for 30min, and at 150°C for 30min, then Continue in the vacuum oven, keep at 250°C for 20min, at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com