Polyvinyl alcohol anion-exchange membrane and preparation method thereof

An anion exchange membrane and polyvinyl alcohol technology, applied in the chemical field, can solve problems such as secondary pollutants, unenvironmental protection of raw materials and preparation process, secondary pollution of solid waste, etc., and achieve the effect of increasing adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

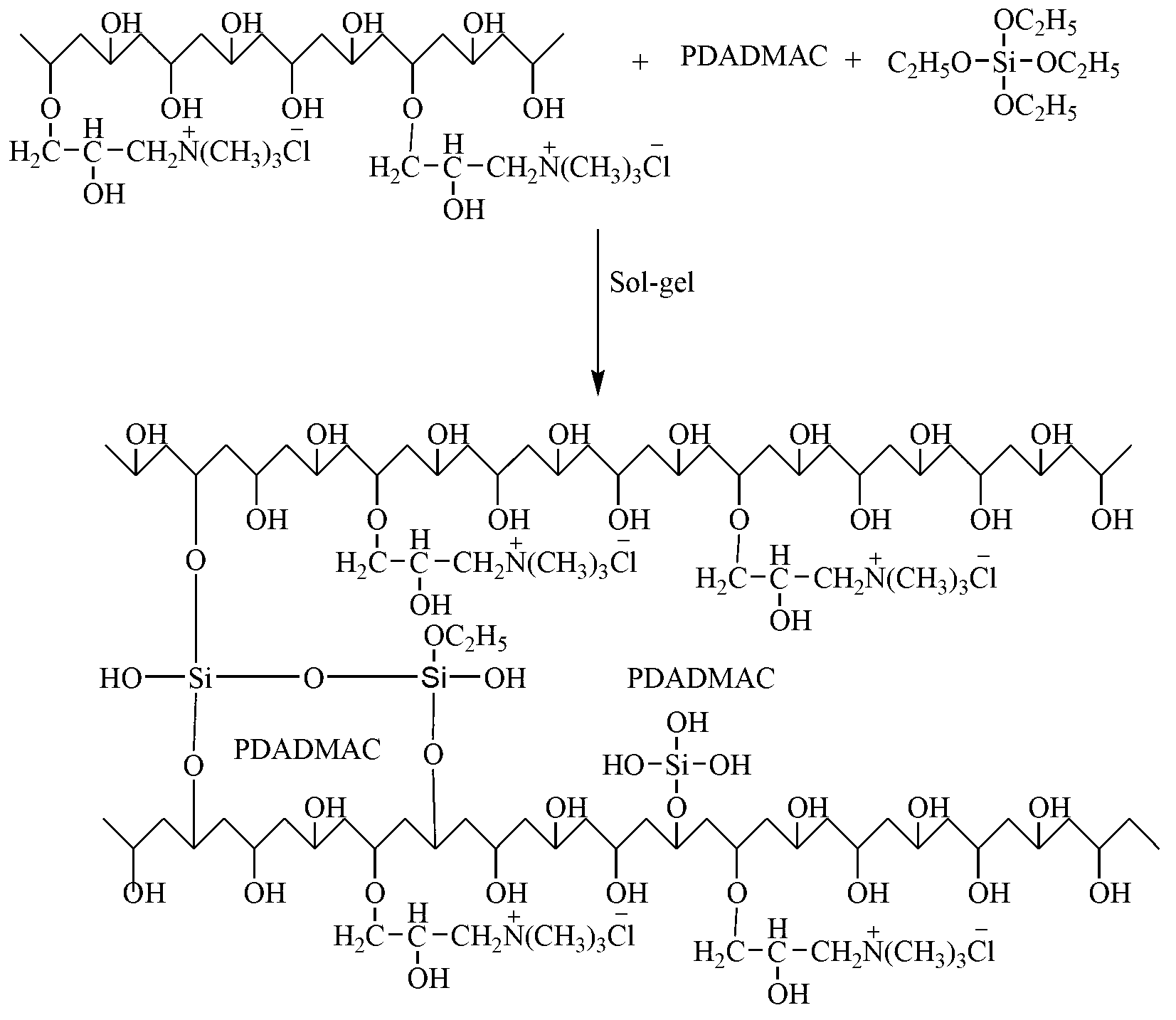

[0057] Example 1 Preparation of Polyvinyl Alcohol Anion Exchange Membrane

[0058] 1. Preparation of quaternized polyvinyl alcohol:

[0059] Step a1: Put 3g of polyvinyl alcohol in a three-necked bottle, add an appropriate amount of deionized water, stir and swell, then gradually raise the temperature to 90°C, fully dissolve to obtain a viscous liquid polyvinyl alcohol aqueous solution, and then gradually cool down to At 65°C, add an appropriate amount of KOH aqueous solution (the molar ratio of KOH and polyvinyl alcohol hydroxyl group is 1.4:1) for alkalization, and then slowly add an aqueous solution of 3-chloro-2-hydroxypropyltrimethylammonium chloride ( The molar ratio of 3-chloro-2-hydroxypropyltrimethylammonium chloride to polyvinyl alcohol hydroxyl was 1:1), stirred and reacted for 4 hours to obtain a yellow liquid mixture;

[0060] Step a2: Slowly pour the yellow liquid mixture into absolute ethanol to precipitate a white solid, wash the white solid repeatedly with ...

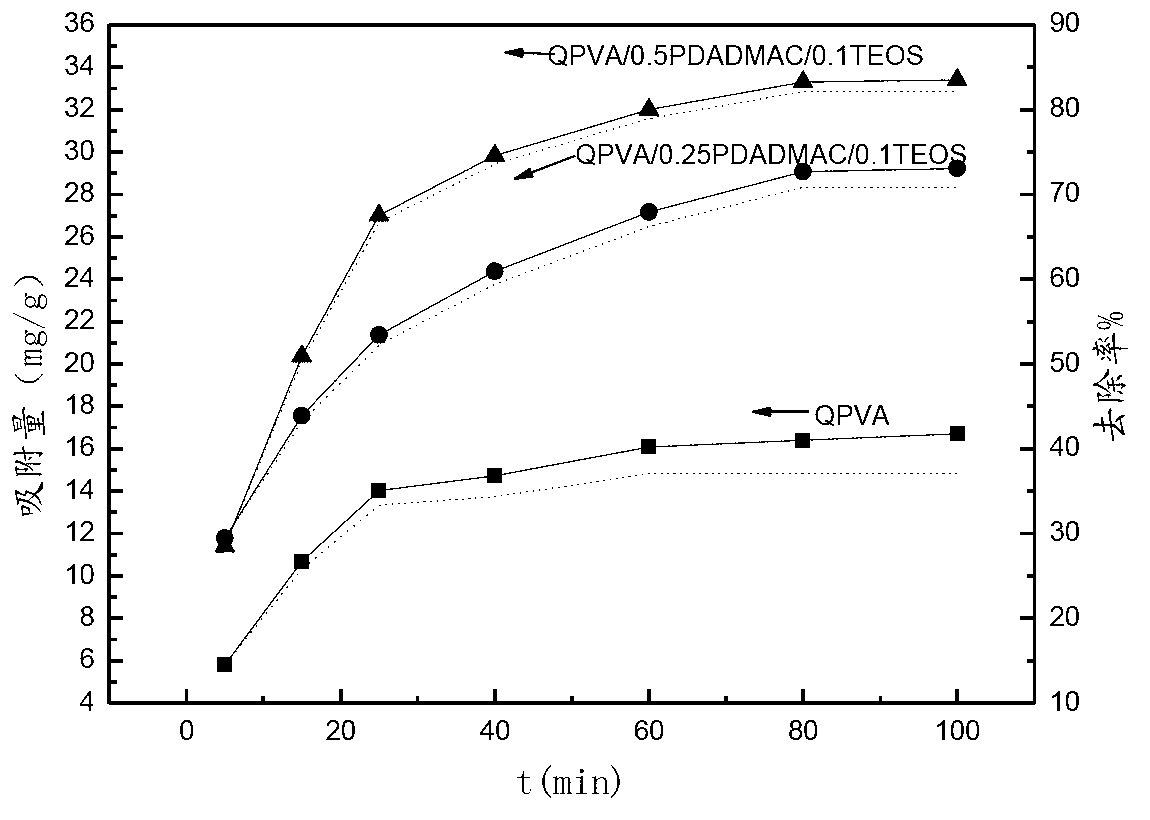

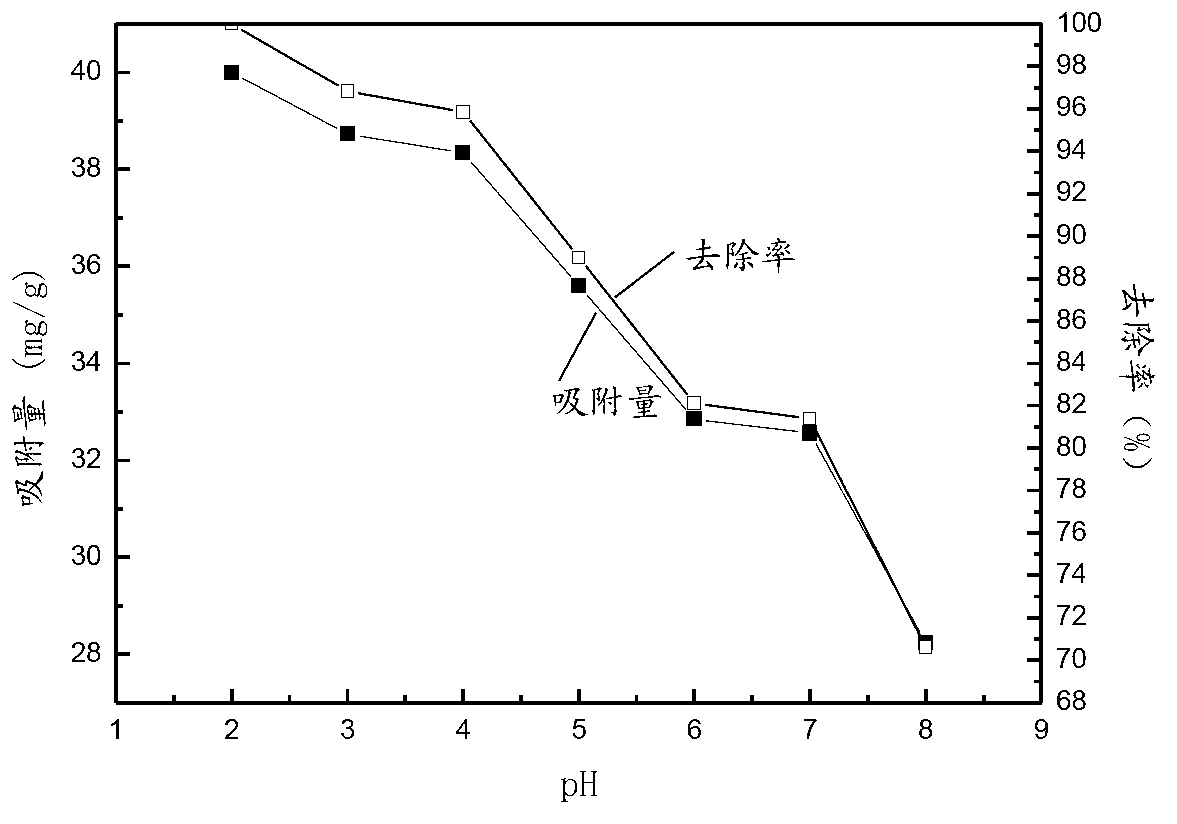

Embodiment 2

[0064] Example 2 Preparation of Polyvinyl Alcohol Anion Exchange Membrane

[0065] In this embodiment, the quaternized polyvinyl alcohol prepared in Example 1 is used to prepare a polyvinyl alcohol anion exchange membrane, and the specific method is as follows:

[0066] Step a: Add quaternized polyvinyl alcohol into deionized water, gradually heat up to 80°C after stirring and swelling, and obtain a 10wt% aqueous solution of quaternized polyvinyl alcohol after fully dissolving; at the same time, polydimethyldiallyl Ammonium chloride was added to deionized water, and magnetically stirred at normal temperature to obtain an aqueous solution of 8wt% polydimethyldiallylammonium chloride; 18.18g of the above-mentioned quaternized polyvinyl alcohol aqueous solution and 1.82g polydimethyldiene Propyl ammonium chloride aqueous solution was mixed evenly (the total weight of the mixed solution was 20g) to obtain the initial mixed solution;

[0067] Step b: Add a little 0.1mol / L hydroc...

Embodiment 3

[0069] Example 3 Preparation of Polyvinyl Alcohol Anion Exchange Membrane

[0070] In this embodiment, the quaternized polyvinyl alcohol prepared in Example 1 is used to prepare a polyvinyl alcohol anion exchange membrane, and the specific method is as follows:

[0071] Step a: Add the prepared quaternized polyvinyl alcohol into deionized water, gradually heat up to 80°C after stirring and swelling, and obtain a 10wt% aqueous solution of quaternized polyvinyl alcohol after fully dissolving; Allyl ammonium chloride was added to deionized water, and magnetically stirred at normal temperature to obtain 8wt% polydimethyldiallyl ammonium chloride aqueous solution; 16g of the above-mentioned quaternized polyvinyl alcohol aqueous solution and 4g polydimethyldiallyl The allyl ammonium chloride aqueous solution was mixed evenly (the total weight of the mixed solution was 20g) to obtain the initial mixed solution;

[0072] Step b: Add a little 0.1mol / L hydrochloric acid solution drop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com