A kind of electric pulse preparation method of dissolution type perovskite

A technology of electric pulse and perovskite, which is applied in the direction of chemical instruments and methods, circuits, electrical components, etc., can solve the problems of damage to the matrix, low dissolution efficiency, etc., and achieve the effect of convenient operation, simple equipment, and prevention of power failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 1. Preparation of LSCN powder

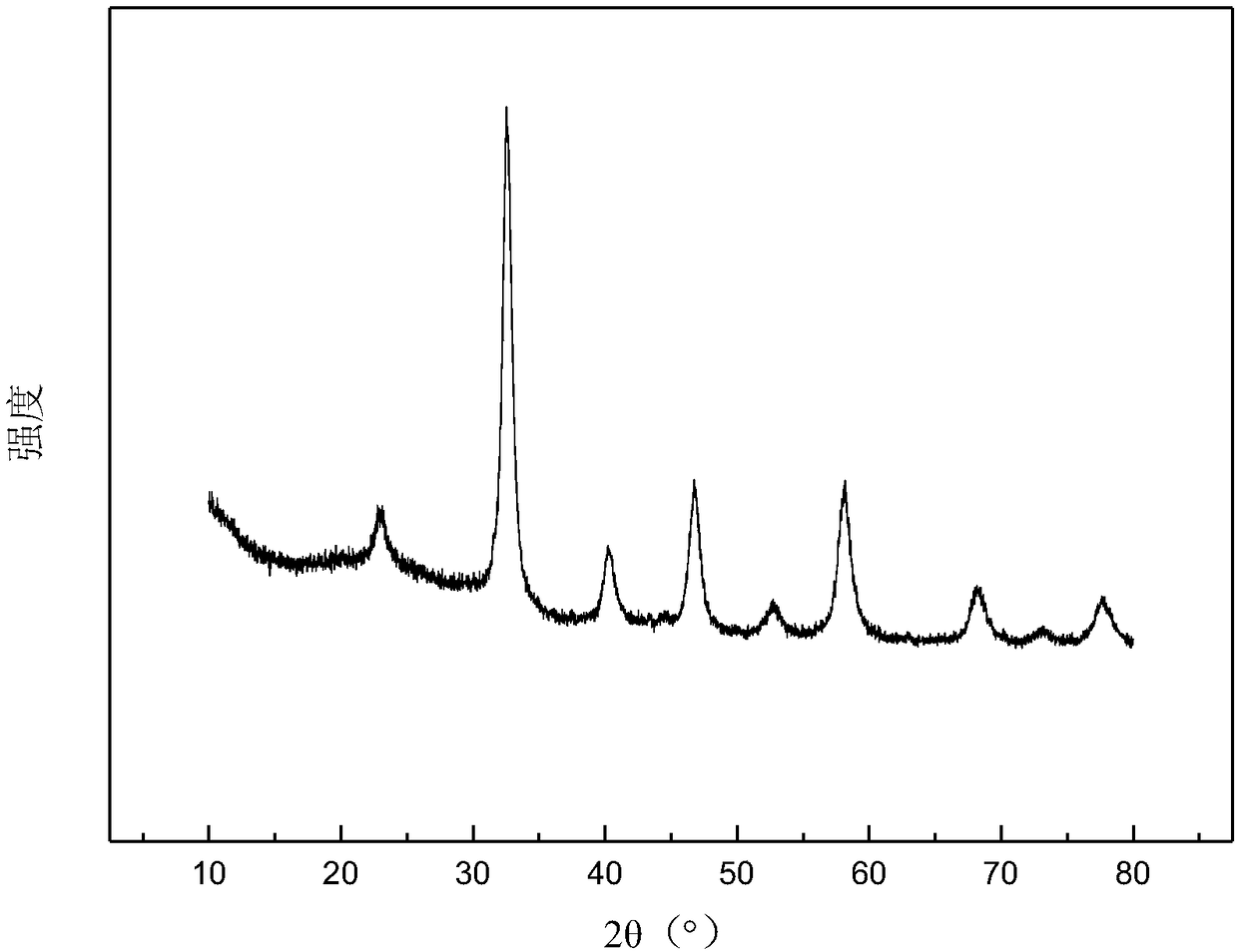

[0039] 0.85mol La(NO 3 ) 3 ·6H 2 O, 0.15mol Sr(NO 3 ) 2 , 0.9mol Cr(NO 3 ) 3 9H 2 O and 0.1molNi(NO 3 ) 2 ·6H 2 O is dissolved in water to prepare a nitrate solution, mixed with 4 mol citric acid and 4.8 mol ethylene glycol complexing agent, and heated to form a gel state. After drying at 130°C for 3 hours, calcining at 800°C for 2 hours, and collecting the calcined powder to obtain LSCN powder (perovskite powder). The obtained powder XRD diffraction pattern is as follows image 3 shown;

[0040] 2. Powder electric pulse treatment

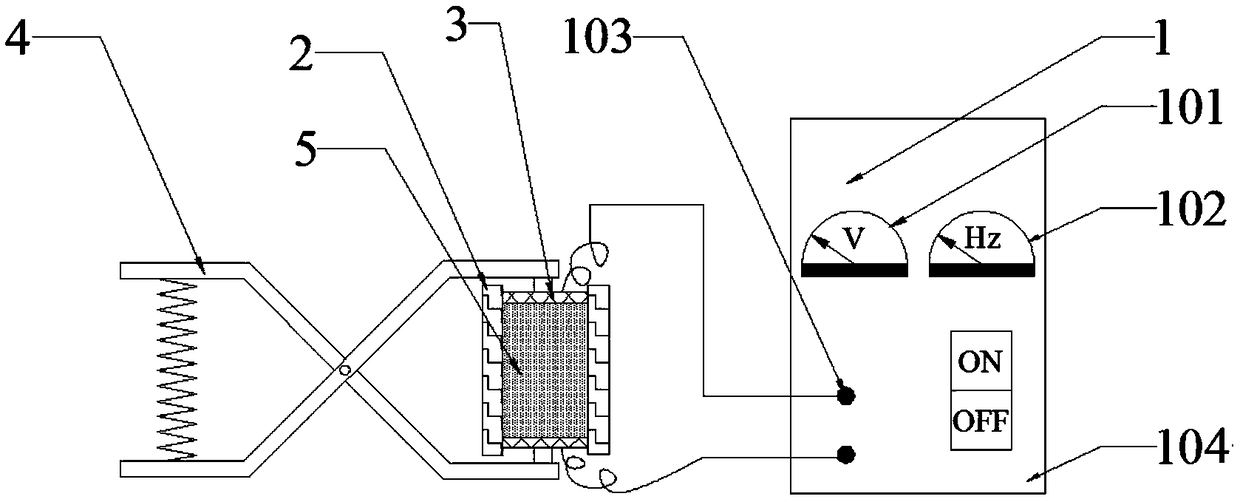

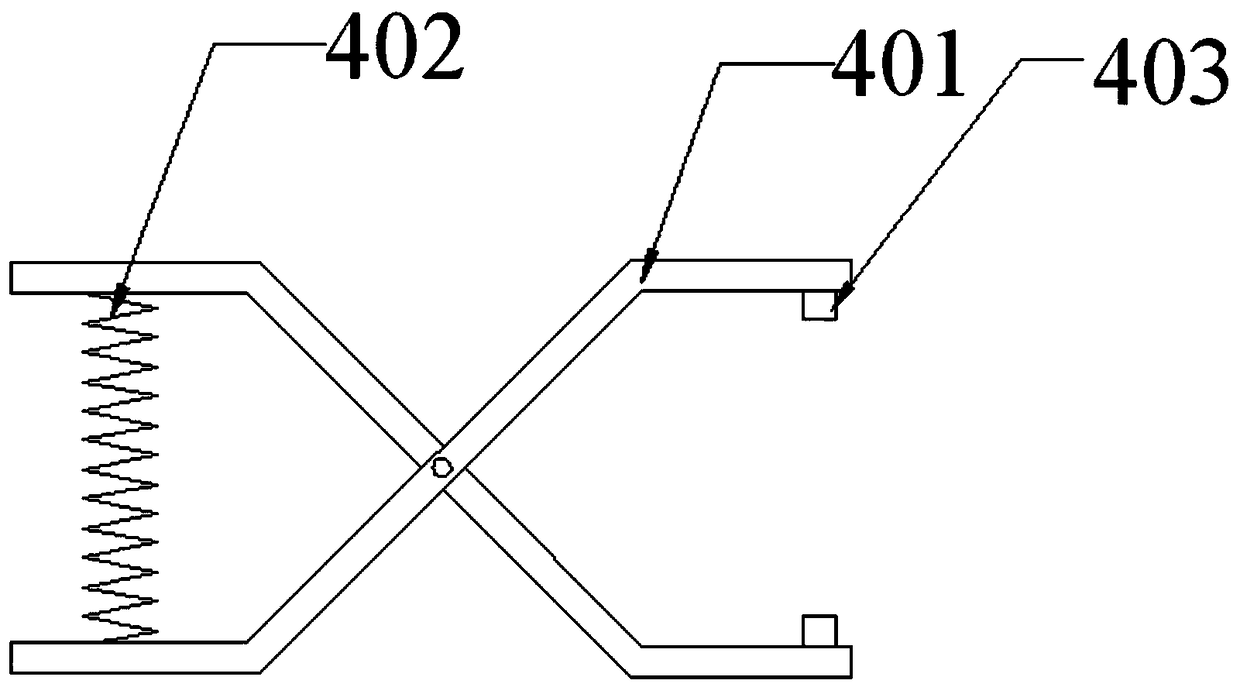

[0041] The perovskite-type oxide powder prepared in the electric pulse treatment step (1) using the electric pulse treatment device for stripping perovskite, as shown in Figure 1 and figure 2 As shown, the device includes:

[0042] The electric pulse generating device 1 is used to form a pulse current and regulate output current parameters. The electrical pulse generating device 1 includes: an...

Embodiment 2

[0049] 1. La 0.85 Sr 0.15 Cr 0.9 Ni 0.1 o 3 Powder preparation

[0050] Dissolve 0.85 mol of lanthanum nitrate, 0.15 mol of strontium nitrate, 0.9 mol of chromium nitrate and 0.1 mol of nickel nitrate in water to prepare a nitrate solution, mix 4 mol of citric acid and 4.8 mol of ethylene glycol complexing agent, and heat to form a gel state. After drying at 130°C for 3h, calcining at 800°C for 2h, and collecting the calcined powder, La 0.85 Sr 0.15 Cr 0.9 Ni 0.1 o 3 Powder;

[0051] 2. Powder electric pulse treatment

[0052] Adopt the electric pulse treatment device of the stripping type perovskite that embodiment 1 uses, the La prepared by electric pulse treatment step (1) 0.85 Sr 0.15 Cr 0.9 Ni 0.1 o 3 Powder, the method of use of the device is the same as in Example 1, and the electric pulse treatment parameters are as follows: pulse voltage 400V, pulse frequency 5Hz, pulse treatment time 300s, to obtain Ni-dissolved La 0.85 Sr 0.15 Cr 0.9 Ni 0.1 o 3 ...

Embodiment 3

[0054] Adopt the electric pulse treatment device of the stripping type perovskite used in embodiment 1, the electric pulse treatment is according to the LSCN powder prepared in embodiment 1 step (1), the use method of the device is the same as embodiment 1, and the electric pulse treatment parameters are as follows: pulse The voltage is 700V, the pulse frequency is 1Hz, and the pulse processing time is 30s, and the Ni-dissolved La 0.85 Sr 0.15 Cr 0.9 Ni 0.1 o 3 Powder; the XRD diffraction pattern of the powder with dissolution properties has a new diffraction peak at around 2θ=44.6°, and the phenomenon is obvious. Compared with the PDF card, it can be seen that this place corresponds to the (111) crystal plane of the Ni element, which can prove After the electric pulse treatment, the Ni element is dissolved from the inside of the perovskite powder, which can effectively improve the catalytic performance, coking resistance and carbon deposition resistance of the material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com