A biomedical degradable corrosion-resistant high-strength magnesium alloy and its preparation method

A biomedical and magnesium alloy technology, applied in medical science, surgery, etc., can solve the problems of unfavorable alloy biocompatibility, harsh storage and smelting conditions, high price, etc., and achieve good comprehensive mechanical properties and blood compatibility. , the effect of reducing the corrosion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

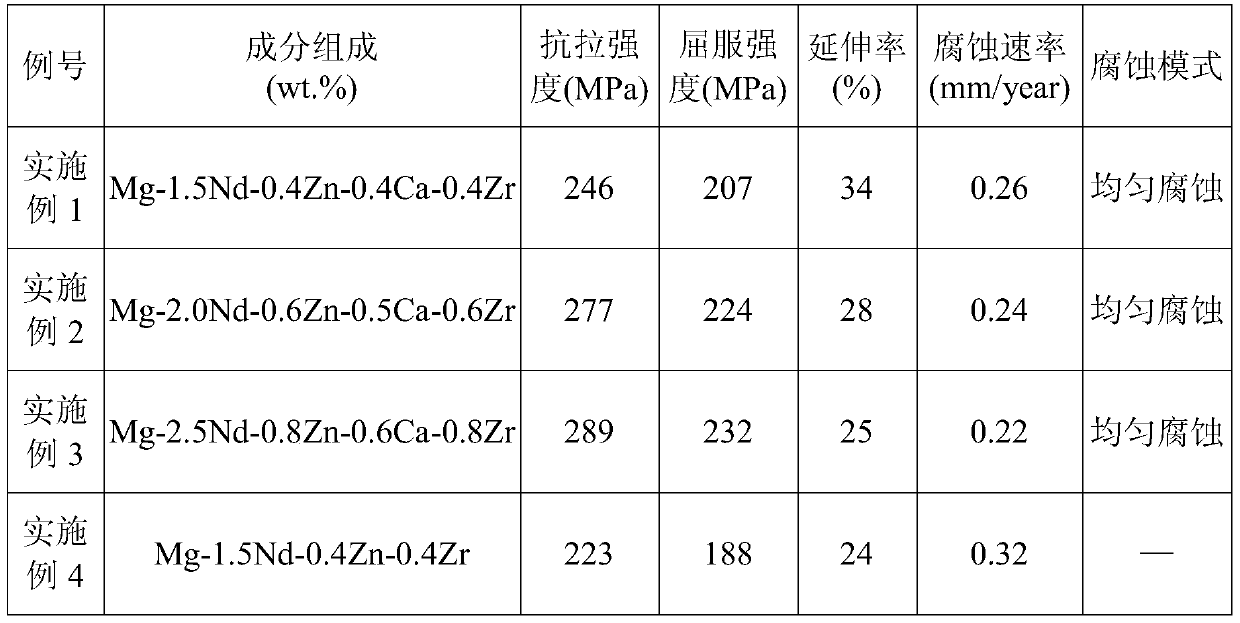

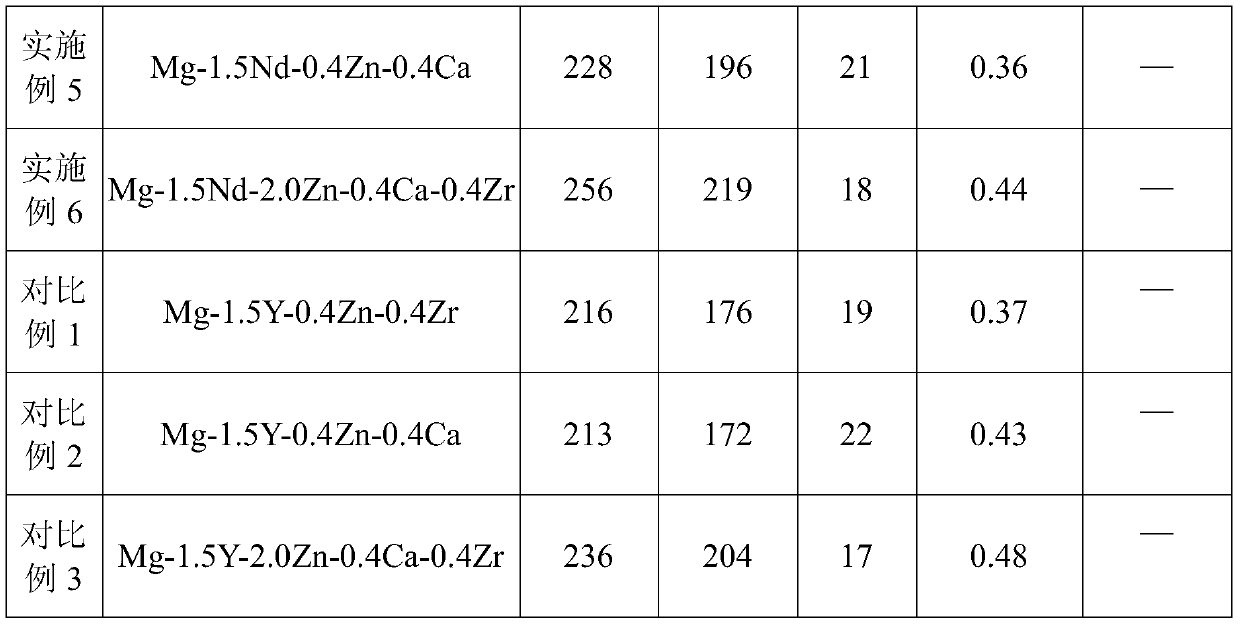

Embodiment 1

[0038] This embodiment provides a biomedical degradable corrosion-resistant high-strength magnesium alloy. Based on the total weight of the magnesium alloy as 100%, its composition is: Nd 1.5%, Zn 0.4%, Ca 0.4%, Zr 0.4% and Mg balance.

[0039] The magnesium alloy is prepared through the following steps:

[0040] (1) In a vacuum smelting furnace, the pure magnesium with a purity of 99.99wt.% or more, the pure Zn with a purity of 99.99wt.% or more, the pure Ca with a purity of 99.99wt.% or more, and the middle of Mg-30wt.% Nd are melted sequentially Alloy, Mg-30wt.% Zr intermediate alloy, control the temperature of the alloy melt to be 740-760°C when melting. After all the raw materials are melted, argon gas is introduced to carry out gas stirring in a vacuum environment, and the stirring time is 40 min.

[0041] (2) Pass SF to the surface of the melt after stirring 6 with CO 2 Mixed gas (SF in the mixed gas 6 :CO 2 The volume ratio is 1:100) for protection, and at the sa...

Embodiment 2

[0047] This embodiment provides a biomedical degradable corrosion-resistant high-strength magnesium alloy. Based on the total weight of the magnesium alloy as 100%, its composition is: Nd 2.0%, Zn 0.6%, Ca 0.5%, Zr 0.6% and Mg balance.

[0048] The magnesium alloy is prepared through the following steps:

[0049] (1) In a vacuum smelting furnace, the pure magnesium with a purity of 99.99wt.% or more, the pure Zn with a purity of 99.99wt.% or more, the pure Ca with a purity of 99.99wt.% or more, and the middle of Mg-30wt.% Nd are melted sequentially Alloy, Mg-30wt.% Zr intermediate alloy, control the temperature of the alloy melt to be 740-760°C when melting. After all the raw materials are melted, argon gas is introduced to carry out gas stirring in a vacuum environment, and the stirring time is 40 min.

[0050] (2) Pass SF to the surface of the melt after stirring 6 with CO 2 Mixed gas (SF in the mixed gas 6 :CO 2 The volume ratio is 1:100) for protection, and at the sa...

Embodiment 3

[0056] This embodiment provides a biomedical degradable corrosion-resistant high-strength magnesium alloy. Based on the total weight of the magnesium alloy as 100%, its composition is: Nd 2.5%, Zn 0.8%, Ca 0.6%, Zr 0.8% and Mg balance.

[0057] The magnesium alloy is prepared through the following steps:

[0058] (1) In a vacuum smelting furnace, the pure magnesium with a purity of 99.99wt.% or more, the pure Zn with a purity of 99.99wt.% or more, the pure Ca with a purity of 99.99wt.% or more, and the middle of Mg-30wt.% Nd are melted sequentially Alloy, Mg-30wt.% Zr intermediate alloy, control the temperature of the alloy melt to be 740-760°C when melting. After all the raw materials are melted, argon gas is introduced to carry out gas stirring in a vacuum environment, and the stirring time is 40 min.

[0059] (2) Pass SF to the surface of the melt after stirring 6 with CO 2 Mixed gas (SF in the mixed gas 6 :CO 2 The volume ratio is 1:100) for protection, and at the sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com