Biological water soluble fertilizer and preparation method thereof

A water-soluble fertilizer and biological technology, which is applied in the preparation of organic fertilizers, the treatment of biological organic parts, organic fertilizers, etc., can solve the problems that microbial fertilizers cannot work well, affect microbial biological activity, and reduce microbial survival rates, etc., to achieve Improve crop quality, prevent fertilizer agglomeration, remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

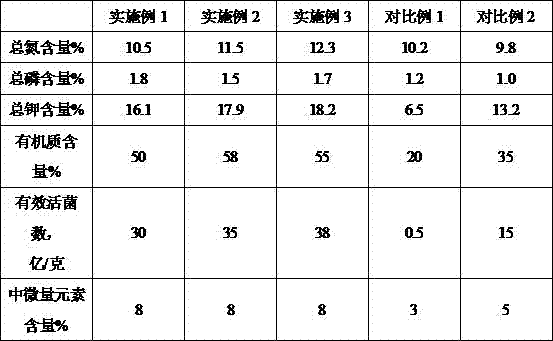

Examples

Embodiment 1

[0024] A biological water-soluble fertilizer, which is made of the following raw materials in parts by weight: 80-100 parts of urea, 20-40 parts of monoammonium phosphate, 1-10 parts of potassium sulfate, 3-5 parts of ammonium molybdate, potassium fulvic acid 30-40 parts, 10-15 parts of calcium ammonium nitrate, 10-15 parts of amino acid powder, 1-5 parts of borax, 5-10 parts of anti-caking agent, 3-8 parts of ferrous sulfate, 1-5 parts of manganese sulfate, 1-5 parts of chelating agent, 20-40 parts of fermented freeze-dried powder, 1-3 parts of garlic polysaccharide.

[0025] The anti-caking agent is made of pullulan-polyglutamic acid cross-linked polymer and sodium hydroxymethylcellulose at a weight ratio of 1:3.

[0026] The chelating agent is made of nitrilotriacetic acid and acrylic acid-N-isopropylacrylamide copolymer in a weight ratio of 3:5.

[0027] The fermented freeze-dried powder is prepared according to the following method: oyster powder and hazelnut meal are mi...

Embodiment 2

[0038] A biological water-soluble fertilizer, which is made of the following raw materials in parts by weight: 80-100 parts of urea, 20-40 parts of monoammonium phosphate, 1-10 parts of potassium sulfate, 3-5 parts of ammonium molybdate, potassium fulvic acid 30-40 parts, 10-15 parts of calcium ammonium nitrate, 10-15 parts of amino acid powder, 1-5 parts of borax, 5-10 parts of anti-caking agent, 3-8 parts of ferrous sulfate, 1-5 parts of manganese sulfate, 1-5 parts of chelating agent, 20-40 parts of fermented freeze-dried powder, 1-3 parts of garlic polysaccharide.

[0039] The anti-caking agent is made of pullulan-polyglutamic acid cross-linked polymer and sodium hydroxymethylcellulose at a weight ratio of 1:3.

[0040] The chelating agent is made of nitrilotriacetic acid and acrylic acid-N-isopropylacrylamide copolymer in a weight ratio of 3:5.

[0041] The fermented freeze-dried powder is prepared according to the following method: mix oyster powder and hazelnut meal ac...

Embodiment 3

[0047] A biological water-soluble fertilizer, which is made of the following raw materials in parts by weight: 80-100 parts of urea, 20-40 parts of monoammonium phosphate, 1-10 parts of potassium sulfate, 3-5 parts of ammonium molybdate, potassium fulvic acid 30-40 parts, 10-15 parts of calcium ammonium nitrate, 10-15 parts of amino acid powder, 1-5 parts of borax, 5-10 parts of anti-caking agent, 3-8 parts of ferrous sulfate, 1-5 parts of manganese sulfate, 1-5 parts of chelating agent, 20-40 parts of fermented freeze-dried powder, 1-3 parts of garlic polysaccharide.

[0048] The anti-caking agent is made of pullulan-polyglutamic acid cross-linked polymer and sodium hydroxymethylcellulose at a weight ratio of 1:3.

[0049] The chelating agent is made of nitrilotriacetic acid and acrylic acid-N-isopropylacrylamide copolymer in a weight ratio of 3:5.

[0050] The fermented freeze-dried powder is prepared according to the following method: mix oyster powder and hazelnut meal ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com