Titanium silicon molecular sieve, preparation method and applications thereof, and cyclic ketone oxidation method

A titanium-silicon molecular sieve and silicon-titanium ratio technology, applied in molecular sieve catalysts, carboxylate preparation, chemical instruments and methods, etc., can solve problems such as small grain size, and achieve large amount of skeleton titanium, improved selectivity and stability. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

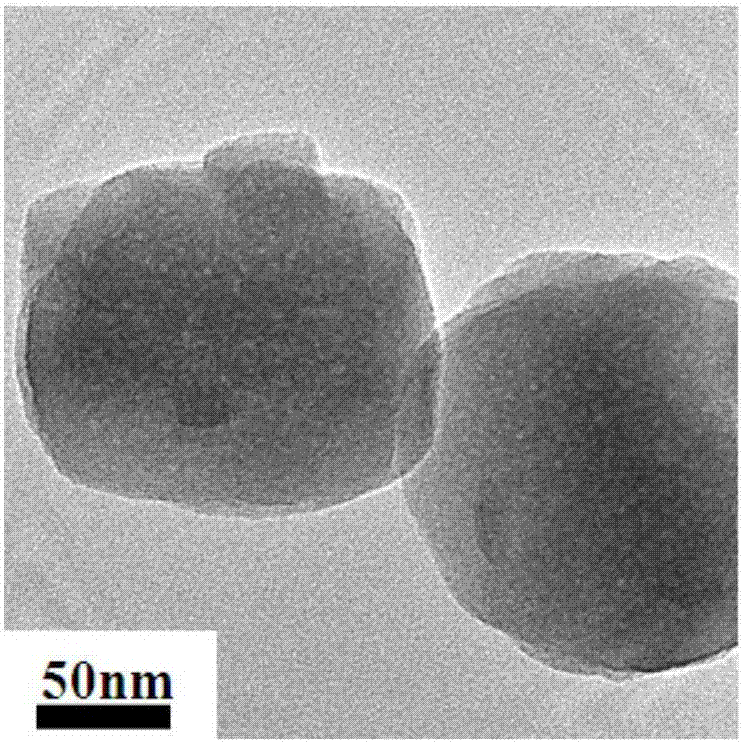

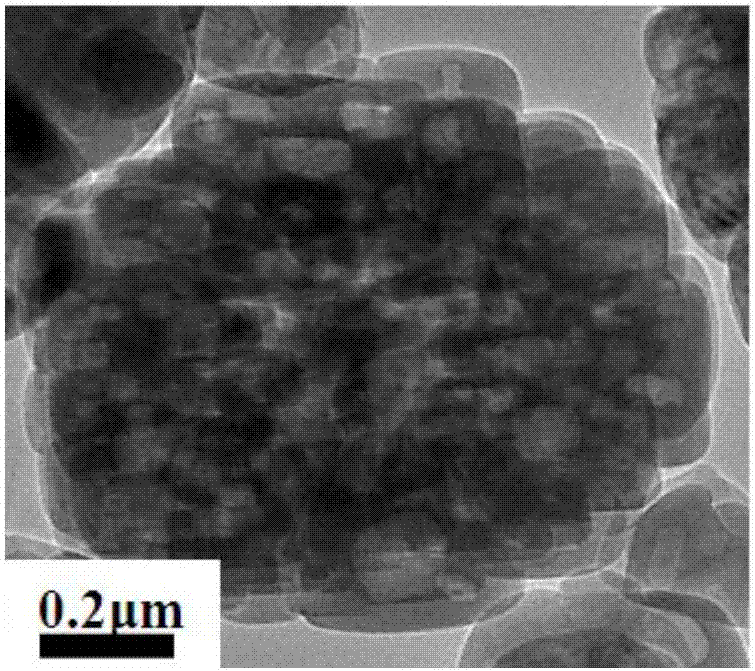

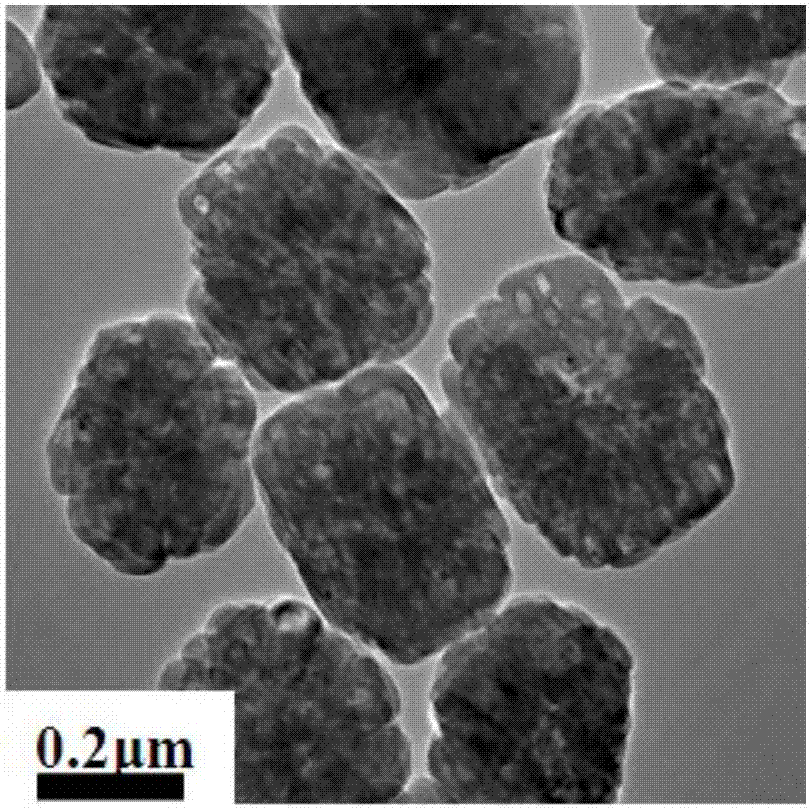

[0027] According to a preferred embodiment of the present invention, the titanium-silicon molecular sieve is composed of nano-scale hollow crystal particles with a particle size of 20-100 nm, and the maximum diameter of the cavity of the nano-scale hollow crystal particles is 2-80 nm. Titanium Silica Molecular Sieve I 960 / I 550 The value is 0.725-0.825.

[0028] In the present invention, the titanium-silicon molecular sieve is formed by agglomerating nanoscale hollow crystal particles and detected by a transmission electron microscope.

[0029] In the present invention, the maximum diameter length of the cavity of the nanoscale hollow crystal particles can also be detected by a transmission electron microscope.

[0030] In the present invention, I 960 Refers to the infrared spectrum, 960cm -1 Absorption peak intensity at , I 550 Refers to the infrared spectrum, 550cm -1 Absorption peak intensity at , I 960 / I 550 The value indicates 960cm -1 Absorption peak intensity...

Embodiment 1

[0108] Add 20 grams of silicon source tetraethyl orthosilicate to tetrapropyl ammonium hydroxide aqueous solution and stir to mix evenly, then add tetrabutyl titanate and mix well to obtain the molar composition of the mixture as silicon source: titanium source: organic base: Water = 100: 2: 15: 1000, then put into a stainless steel sealed reactor and treat at a temperature of 100°C and autogenous pressure for 24 hours (stage (1)); hydrothermal treatment at a temperature of 200°C and autogenous pressure for 6 hours (stage ( 2)); hydrothermal treatment at a temperature of 170°C and autogenous pressure for 48 hours (stage (3)), the heating rate from room temperature to stage (1) is 2°C / min, and the heating rate from stage (1) to stage (2) is 15°C / min, and the cooling rate from stage (2) to stage (3) is 10°C / min;

[0109] The resultant was filtered, washed with water, dried naturally, and calcined at 550°C for 5 hours, then the solid product was mixed with an aqueous solution of ...

Embodiment 2

[0112] Add 20 grams of silicon source solid silica gel silica into tetrapropyl ammonium hydroxide aqueous solution and stir to mix evenly, then add tetrabutyl titanate and mix evenly to obtain the molar composition of the mixture: silicon source: titanium source: organic base: Water = 100: 1: 20: 600, then put into a stainless steel sealed reactor, hydrothermal treatment at a temperature of 90°C and autogenous pressure for 12 hours (stage (1)); hydrothermal treatment at a temperature of 190°C and autogenous pressure for 4 hours (stage ( 2)); hydrothermal treatment at a temperature of 170°C and autogenous pressure for 36 hours (stage (3)), the heating rate from room temperature to stage (1) was 10°C / min, and the heating rate from stage (1) to stage (2) 20°C / min, the cooling rate from stage (2) to stage (3) is 10°C / min;

[0113] The resultant was filtered, washed with water, dried naturally, and calcined at 550°C for 5 hours. The obtained solid product, water and alkali source h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com