Method for preparing coating on workpiece surface through laser shock peening technology

A technology of laser shock strengthening and workpiece surface application in the direction of pressure inorganic powder coating, which can solve the problems of less equipment inventory, coating preparation, and narrow application fields, so as to avoid uneven distribution of powder, ensure uniform distribution, and avoid dangerous small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

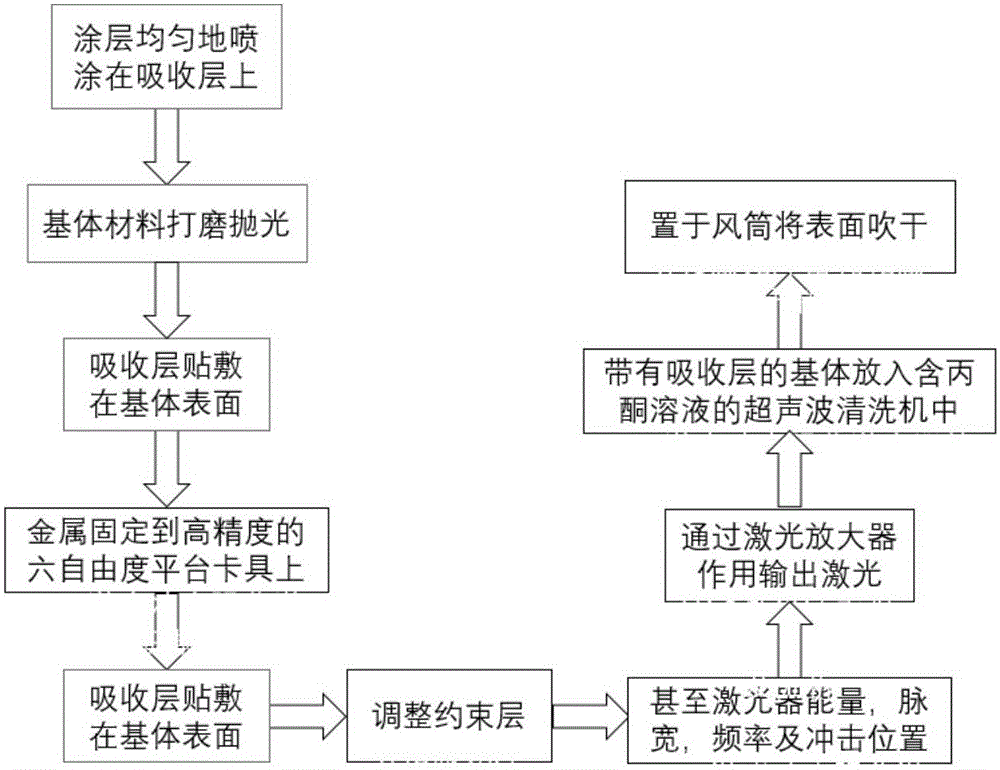

[0024] This embodiment adopts laser shock strengthening technology to prepare iron coating on the surface of TC4 titanium alloy workpiece, and its technological process is as follows Figure 4 As shown, the specific process is as follows:

[0025] The laser strengthening equipment adopts pulsed nanosecond Nd:YAG laser. The impact energy can reach up to 7J, the laser emission frequency is 0.5-2Hz, the pulse width is adjustable from 12-18ns, and the spot diameter is 3mm. The surface of the material is made of black tape or aluminum foil as the absorbing layer, and black tape is used in this embodiment. Deionized water with a thickness of about 2mm was used as a constrained layer, and the experiment was carried out in a dust-free laboratory environment at 22 °C. Pretreatment before the experiment of titanium alloy materials: the surface is polished with 100# sandpaper for rough grinding, then polished with 400#, 800#, 1200#, 2000# sandpaper in turn, and finally polished with po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com