Graphite material with sic doped layer and preparation method thereof

A technology of graphite material and doped layer, which is applied in the field of graphite material with SiC doped layer and its preparation, can solve the problems of low density, excessive residual silicon on the surface, increasing the difficulty of silicon infiltration processing, etc., so as to improve the bonding strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A kind of preparation method of the graphite material with SiC doping layer of the present invention, comprises the following steps:

[0029] 1) Put the mixed powder consisting of silicon powder, flake graphite powder, boron nitride powder, aluminum oxide powder and yttrium oxide powder in a polyurethane ball milling tank, place the ball milling tank in a planetary ball mill, and turn it at 276 rpm Speed ball milling for 0.5h to obtain the silicon source of the liquid phase siliconizing process; wherein, the mass fraction of silicon powder in the mixed powder is 88%, flake graphite powder, boron nitride powder, aluminum oxide powder and yttrium oxide powder in the mixed powder The mass fractions are 2.4%, 8.4%, 0.6%, 0.6%, respectively.

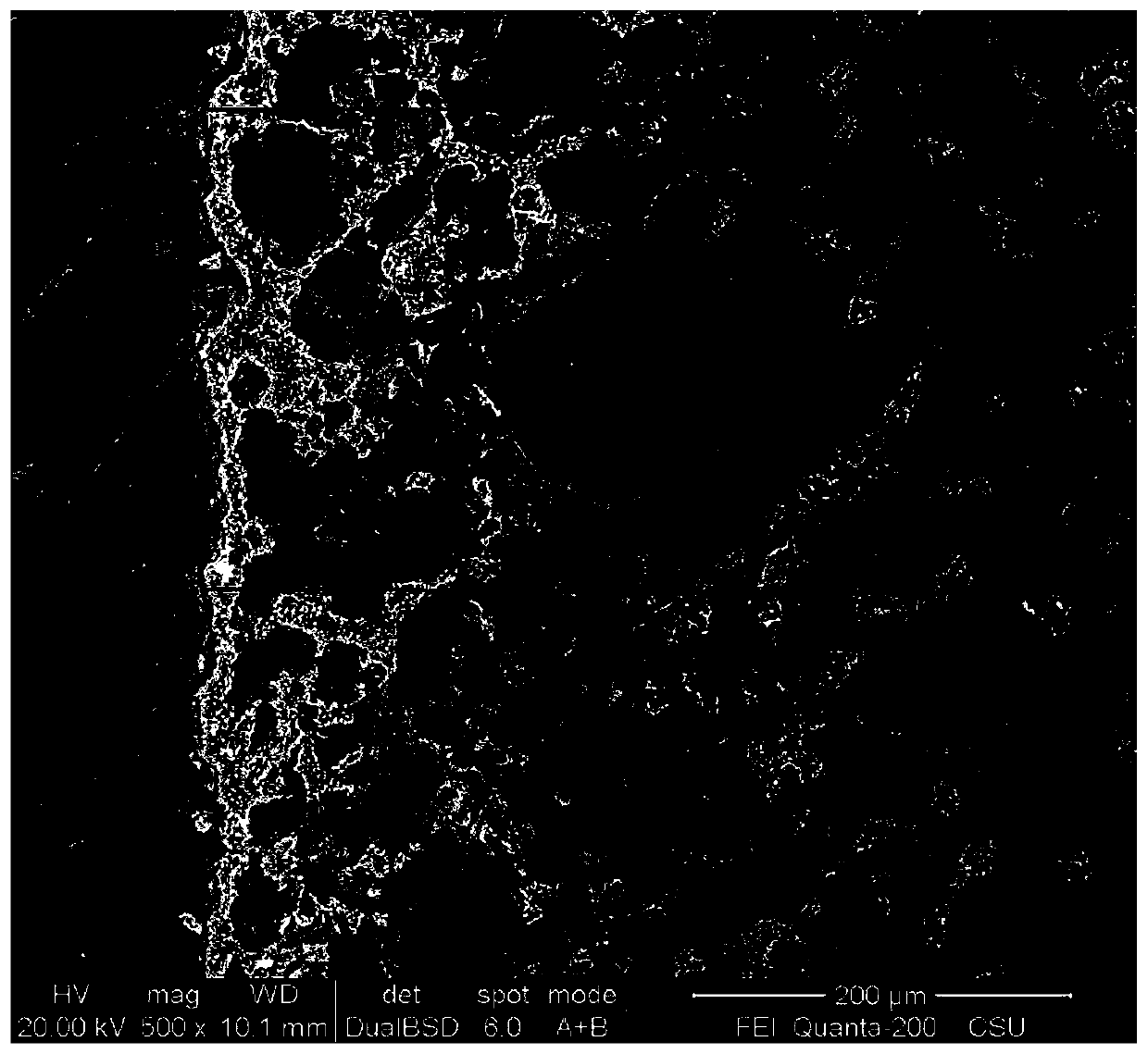

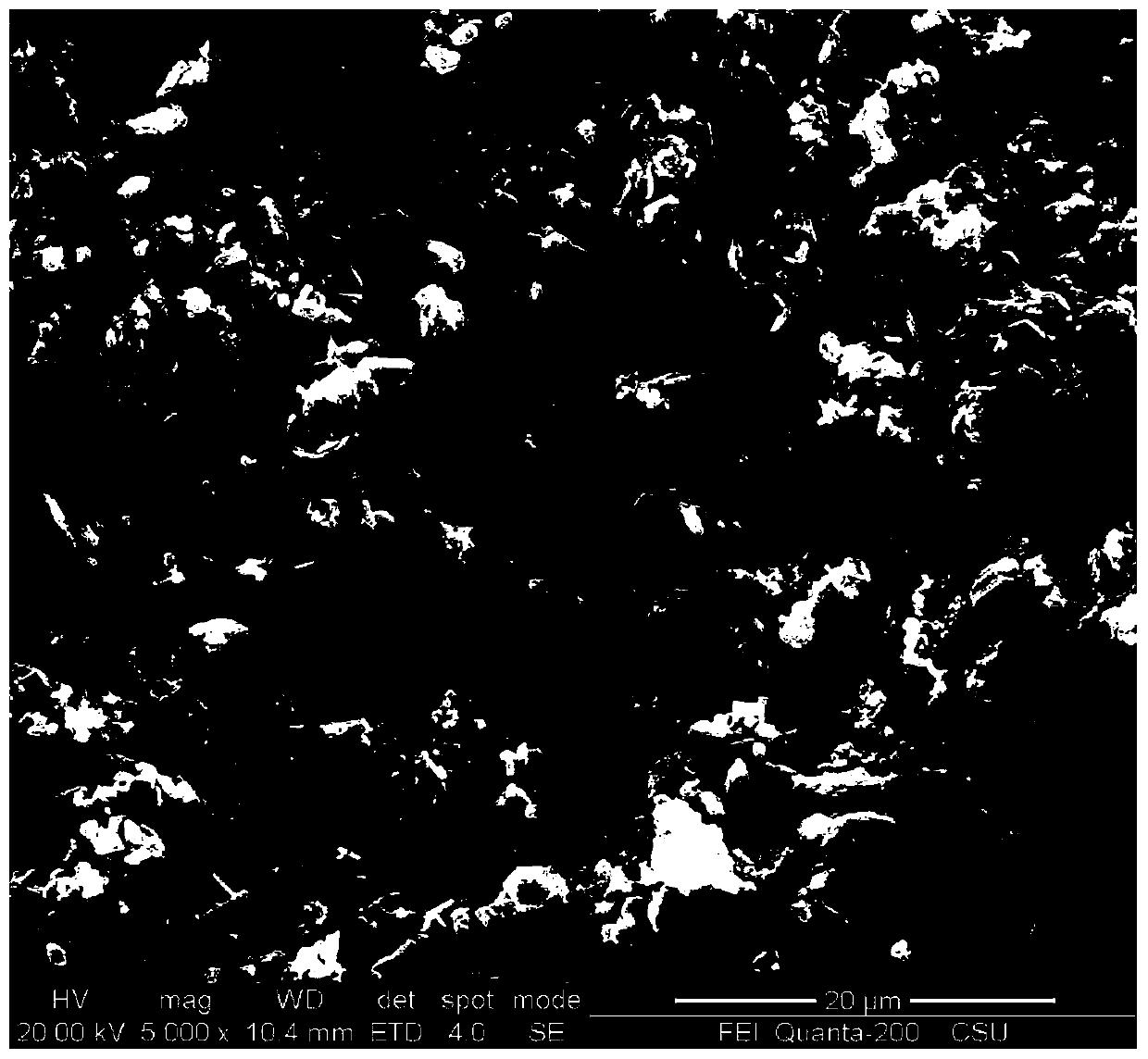

[0030] 2) Under the conditions of 1600°C and 22Pa high-temperature vacuum, use the silicon source obtained in step 1) to sinter the graphite substrate for liquid-phase siliconization (LSI) for 2 hours, so that the liquid-phase silico...

Embodiment 2

[0037] A kind of preparation method of the graphite material with SiC doping layer of the present invention, comprises the following steps:

[0038] 1) Put the mixed powder consisting of silicon powder, carbon powder, boron nitride powder, aluminum oxide powder and yttrium oxide powder in a polyurethane ball milling tank, and place the ball milling tank in a planetary ball mill at a speed of 276 rpm Ball milled for 0.5h to obtain the silicon source of the liquid phase siliconizing process; wherein, the mass fraction of silicon powder in the mixed powder is 84%, and the amount of flake graphite powder, boron nitride powder, aluminum oxide powder and yttrium oxide powder in the mixed powder The mass fractions are 3.2%, 11.2%, 0.8%, and 0.8%, respectively.

[0039] 2) Under the condition of 1600°C and 30Pa high-temperature vacuum, use the silicon source obtained in step 1) to sinter the graphite substrate for liquid-phase silicon infiltration (LSI) for 2 hours, so that the liquid...

Embodiment 3

[0042] A kind of preparation method of the graphite material with SiC doping layer of the present invention, comprises the following steps:

[0043] 1) Put the mixed powder consisting of silicon powder, carbon powder, boron nitride powder, aluminum oxide powder and yttrium oxide powder in a polyurethane ball milling tank, and place the ball milling tank in a planetary ball mill at a speed of 276 rpm Ball milled for 0.5h to obtain the silicon source of the liquid phase siliconizing process; wherein, the mass fraction of silicon powder in the mixed powder is 80%, and the amount of flake graphite powder, boron nitride powder, aluminum oxide powder and yttrium oxide powder in the mixed powder The mass fractions are 4%, 14%, 1%, 1%, respectively.

[0044] 2) Under the condition of 1600°C and 15Pa high-temperature vacuum, use the silicon source obtained in step 1) to sinter the graphite substrate for liquid-phase siliconization (LSI) for 2 hours, so that the liquid-phase silicon can...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com