Expanded polytetrafluoroethylene film coating composite material with functions like heat conduction, heat insulation, electric conduction and electromagnetic shielding and preparation method thereof

A polytetrafluoroethylene film and composite material technology, applied in conductive coatings, polyurea/polyurethane coatings, coatings, etc., can solve problems such as electromagnetic interference, high cost, and large volume, and achieve shielding, heat conduction, heat dissipation, and shielding Good effect of electromagnetic interference and soft fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

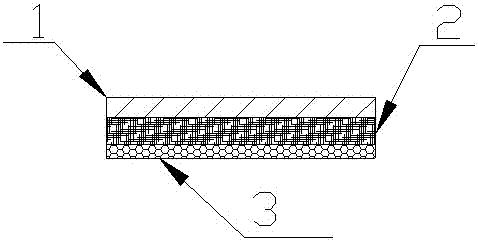

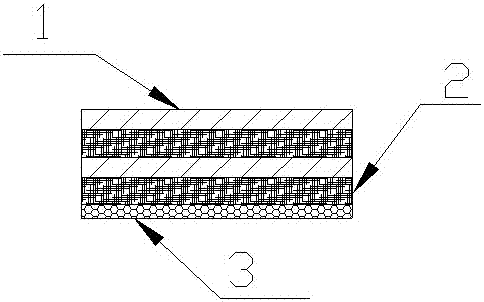

Image

Examples

Embodiment 1

[0039] Embodiment 1: The preparation method of the expanded polytetrafluoroethylene film coating composite material with functions such as heat conduction, heat insulation, conduction, electromagnetic shielding, comprises the following steps:

[0040] 1) Prepare graphene conductive heat transfer coating solution for graphene conductive heat transfer coating, silica airgel coating solution for silica airgel coating and expanded polytetrafluoroethylene membrane respectively ;

[0041] 2) Unwind the expanded polytetrafluoroethylene film at an unwinding speed of 1m / min, and roll-coat the prepared graphene conductive heat transfer coating solution on the film surface;

[0042] 3) Ethyl acetate solvent is volatilized by drying method, and the drying temperature is 100°C;

[0043] 4) Trimming, inspection, winding, coating curing, coating curing temperature is 50°C, time is 24h, and then enters the next coating process;

[0044] 5) Unwind the expanded polytetrafluoroethylene film co...

Embodiment 2

[0076] Embodiment 2: the preparation method of the expanded polytetrafluoroethylene film coating composite material with functions such as heat conduction, heat insulation, conduction, electromagnetic shielding, comprises the following steps:

[0077] 1) Prepare graphene conductive heat transfer coating solution for graphene conductive heat transfer coating, silica airgel coating solution for silica airgel coating and expanded polytetrafluoroethylene membrane respectively ;

[0078] 2) Unwind the expanded polytetrafluoroethylene film at an unwinding speed of 3m / min, and roll-coat the prepared graphene conductive heat transfer coating solution on the film surface;

[0079] 3) Ethyl acetate solvent is volatilized by drying method, and the drying temperature is 150°C;

[0080] 4) Trimming, inspection, winding, coating curing, coating curing temperature is 60 ℃, time is 24h, and then enters the next coating process;

[0081] 5) Unwind the expanded polytetrafluoroethylene film co...

Embodiment 3

[0113] Embodiment 3: the preparation method of the expanded polytetrafluoroethylene film coating composite material with functions such as heat conduction, heat insulation, conduction, electromagnetic shielding, comprises the following steps:

[0114] 1) Prepare graphene conductive heat transfer coating solution for graphene conductive heat transfer coating, silica airgel coating solution for silica airgel coating and expanded polytetrafluoroethylene membrane respectively ;

[0115] 2) Unwind the expanded polytetrafluoroethylene film at an unwinding speed of 5m / min, and roll-coat the prepared graphene conductive heat transfer coating solution on the film surface;

[0116] 3) Ethyl acetate solvent is volatilized by drying method, and the drying temperature is 200°C;

[0117] 4) Trimming, inspection, winding, coating curing, coating curing temperature is 70 ℃, time is 24h, and then enters the next coating process;

[0118] 5) Unwind the expanded polytetrafluoroethylene film coat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com