A spray tower simultaneously removes ship exhaust no x and so 2 Methods

A ship tail gas and spray tower technology, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of increasing floor space, increasing equipment investment, and complex components of final products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention is described in more detail below in conjunction with accompanying drawing:

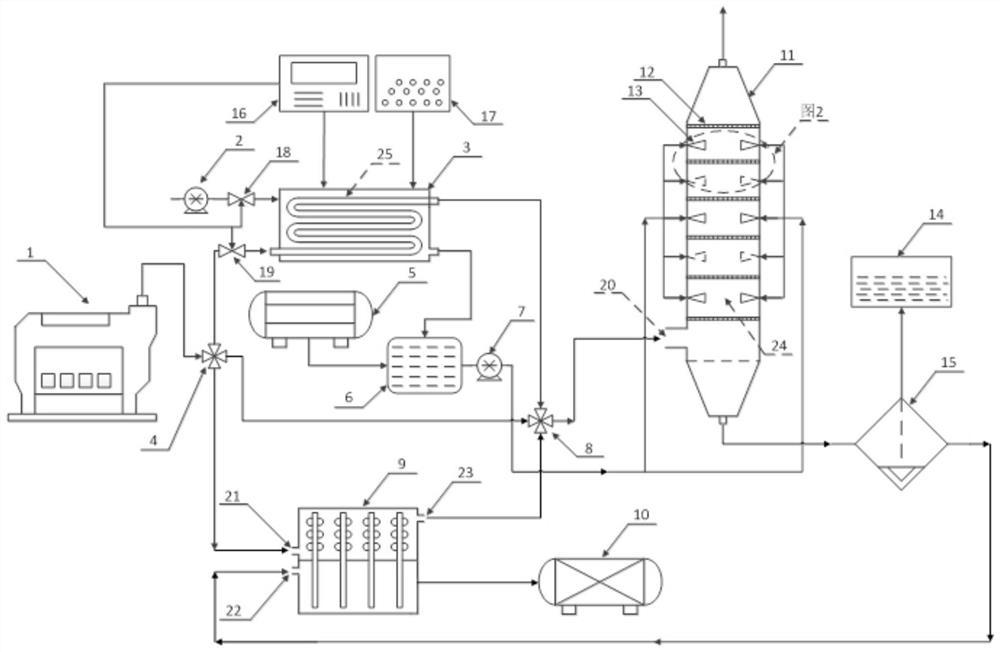

[0051] figure 1 It is a schematic flow chart of the present invention. The exhaust gas produced by the marine diesel engine 1 flows through the pipeline through the flue gas four-way diversion control valve 4, and part of the flue gas flows through the flue gas supply control valve 19 and enters the tubular flue 25 in the sodium persulfate seawater solution mixer 3 Inside, heat energy for activation is provided, and then exhausted by the shell-and-tube flue 25 . The tail gas enters the spray scrubber 11 through the flue gas four-way control valve 8 at the inlet of the scrubber. The other part of the flue gas enters the inside of the spray scrubber 11 through the flue gas four-way control valve 8 at the inlet of the scrubber and the flue gas inlet 20 of the scrubber. The third part of the flue gas enters the upper part of the waste liquid concentrator 9 through the flue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com