Coal ash based composite phase-change thermal storage material and preparation method thereof

A technology of composite phase change and heat storage materials, which is applied in the field of fly ash-based composite phase change heat storage materials and its preparation, can solve the problems of poor thermal stability and weak heat storage performance, achieve good thermal stability and improve adsorption Sexuality and dispersibility, the effect of enhancing the heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

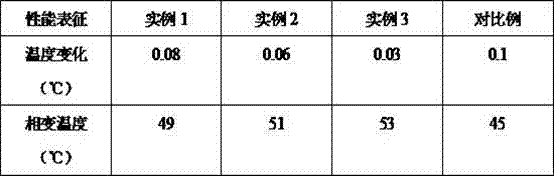

Examples

example 1

[0021] Take 2g of expandable graphite into a mortar and grind it, pass through a 60-mesh sieve, put the sieved expandable graphite powder in a drying oven, dry it at 105 ° C to a constant weight, and then transfer it to a muffle furnace and heat it. to 850°C, heat preservation for 30s, cooled to room temperature, added to 75% ethanol solution, stirred at 180r / min for 20min, then transferred to an ultrasonic disperser for ultrasonic treatment for 5h, filtered to obtain a filter residue, washed with absolute ethanol The filter residue was placed in a vacuum drying oven for 2 times, and kept at 105 °C to constant weight to obtain expanded graphite flakes. Take 100 g of fly ash, put it into a muffle furnace, heat it to 600 °C for calcination for 2 hours, and add 500 g of 500 g after cooling to room temperature. The mass fraction is 1% citric acid solution, stirred at 50 °C for 2 h, filtered to obtain a filter cake, washed with deionized water until the washing liquid is neutral, tr...

example 2

[0023] Take 2.5g of expandable graphite into a mortar and grind it, pass through a 60-mesh sieve, put the sieved expandable graphite powder in a drying oven, dry it at 107 ° C to constant weight, and then transfer it to a muffle furnace, Heated to 900°C, incubated for 35s, cooled to room temperature, added to 75% ethanol solution, stirred at 210r / min for 25min, then transferred to an ultrasonic disperser for 6h ultrasonic treatment, filtered to obtain the filter residue, and used absolute ethanol. After washing the filter residue twice, put it in a vacuum drying oven, and at 107 ℃ to constant weight to obtain expanded graphite flakes, take 150g of fly ash, put it into a muffle furnace, heat it to 625 ℃ for 2 hours, cool to room temperature and add 750g of citric acid solution with mass fraction of 1% was stirred at 55 °C for 2 hours, filtered to obtain a filter cake, washed with deionized water until the washing liquid was neutral, transferred to a vacuum drying box, and dried ...

example 3

[0025] Take 3g of expandable graphite into a mortar and grind, pass through a 60-mesh sieve, put the sieved expandable graphite powder in a drying oven, dry it at 110 ° C to constant weight, then transfer it to a muffle furnace, heat to 950°C, incubated for 40s, cooled to room temperature, added to 75% ethanol solution, stirred at 240r / min for 30min, then transferred to an ultrasonic disperser for ultrasonic treatment for 8h, filtered to obtain a filter residue, washed with absolute ethanol After filtering the residue for 3 times, put it in a vacuum drying box, and at 110 ℃ to constant weight to obtain expanded graphite flakes, take 200 g of fly ash, put it into a muffle furnace, heat it to 650 ℃ for 3 hours, and add 1000 g of it after cooling to room temperature. The mass fraction is 1% citric acid solution, stirred at 60 °C for 3 hours, filtered to obtain a filter cake, washed with deionized water until the washing liquid is neutral, transferred to a vacuum drying box, and dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solidification time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com