Polymer cement waterproof coating

A waterproof coating and polymer technology, applied in the direction of coating, etc., can solve the problems of easy re-swelling of cured film by water, poor waterproof effect, low fastness, etc., to improve performance and firmness, prevent re-swelling, and improve water resistance sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

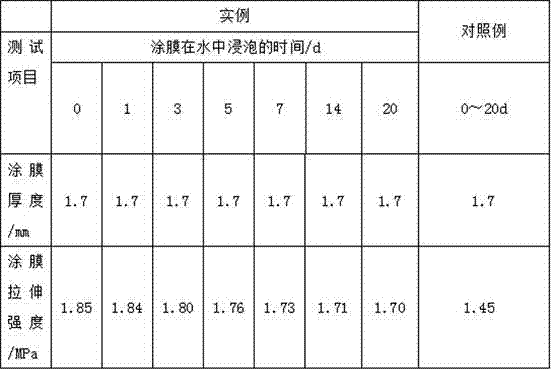

Examples

preparation example Construction

[0019] The preparation method of modified acrylate emulsion:

[0020] (1) The raw materials are calculated in parts by weight, 90-100 parts of distilled water, 70-80 parts of ethyl acrylate, 40-50 parts of methacrylate, 30-35 parts of acrylic acid, 15-18 parts of methyl vinyl dichloride Silane, 14-18 parts of butanol, 10-12 parts of maleic anhydride, 6-8 parts of fatty acid polyoxyethylene ester, 2-6 parts of ammonium persulfate, 1-3 parts of dodecyl betaine, 1-2 parts Lewis acid;

[0021] (2) Put distilled water, ethyl acrylate, methacrylate, methyl vinyl dichlorosilane, polyoxyethylene fatty acid ester, and dodecyl betaine into the reactor, and stir at 200r / min for 40-50min, Use nitrogen to discharge the gas in the reactor, and raise the temperature to 70-75°C, add acrylic acid to the container, mix at 300r / min for 20-30min, then add ammonium persulfate of 70-80% of the total mass of ammonium persulfate, Keep warm for 2-4 hours;

[0022] (3) After the heat preservation is...

example 1

[0029] The preparation method of modified acrylate emulsion:

[0030] (1) The raw materials are calculated in parts by weight, 95 parts of distilled water, 75 parts of ethyl acrylate, 45 parts of methacrylate, 33 parts of acrylic acid, 17 parts of methyl vinyl dichlorosilane, 15 parts of butanol, 11 parts of horse Toric anhydride, 7 parts of polyoxyethylene fatty acid ester, 5 parts of ammonium persulfate, 2 parts of lauryl betaine, 1.5 parts of Lewis acid;

[0031] (2) Put distilled water, ethyl acrylate, methacrylate, methyl vinyl dichlorosilane, fatty acid polyoxyethylene ester, and dodecyl betaine into the reactor, stir at 200r / min for 45min, and use nitrogen Discharge the gas in the reactor, raise the temperature to 73°C, add acrylic acid to the container, mix at 300r / min for 25min, then add ammonium persulfate of 75% of the total mass of ammonium persulfate, and keep warm for 3h;

[0032] (3) After the heat preservation is completed, add maleic anhydride and Lewis acid,...

example 2

[0039] The preparation method of modified acrylate emulsion:

[0040] (1) The raw materials are calculated in parts by weight, 100 parts of distilled water, 80 parts of ethyl acrylate, 50 parts of methacrylate, 35 parts of acrylic acid, 18 parts of methyl vinyl dichlorosilane, 18 parts of butanol, 12 parts of horse Toric anhydride, 8 parts of fatty acid polyoxyethylene ester, 6 parts of ammonium persulfate, 3 parts of lauryl betaine, 2 parts of Lewis acid;

[0041] (2) Put distilled water, ethyl acrylate, methacrylate, methyl vinyl dichlorosilane, fatty acid polyoxyethylene ester, and dodecyl betaine into the reactor, stir at 200r / min for 50min, and use nitrogen Discharge the gas in the reactor, and raise the temperature to 75°C, add acrylic acid to the container, mix at 300r / min for 30min, then add ammonium persulfate of 80% of the total mass of ammonium persulfate, and keep warm for 4h;

[0042] (3) After the heat preservation is completed, add maleic anhydride and Lewis ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com