Temperature compensation surface acoustic wave resonator and preparation method thereof

A surface acoustic wave, temperature compensation technology, applied in electrical components, impedance networks, etc., can solve the problems of difficult process conditions, extremely high control requirements for silicon dioxide material and thickness, and reduce the possibility of brittleness, The effect of improving stability and reliability, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

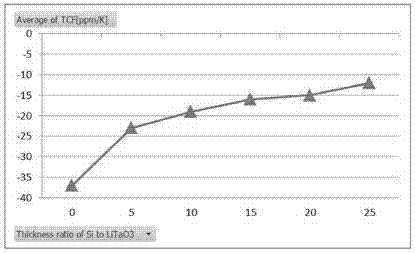

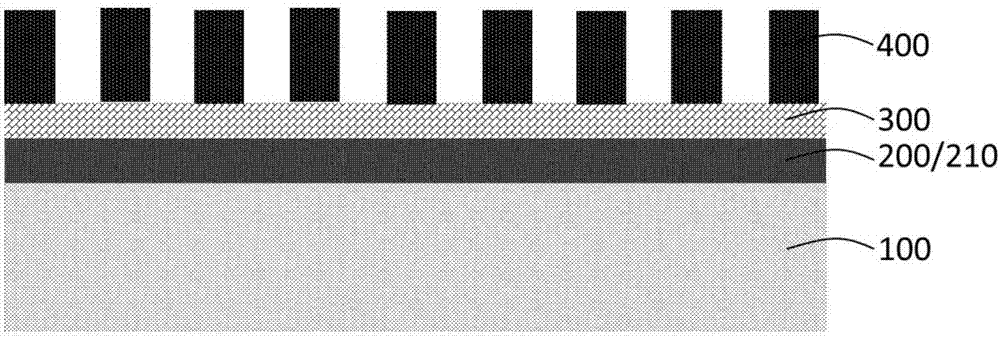

[0028] figure 1 It is a schematic cross-sectional structure diagram of the temperature-compensated surface acoustic wave resonator of the present invention. like figure 1 As shown, the temperature-compensated surface acoustic wave resonator includes a substrate 100, which is used as a supporting substrate, such as a silicon wafer, sapphire, etc.; a first adhesive film layer 200 disposed on the substrate 100; A piezoelectric material substrate 300 is arranged above 100. The piezoelectric material substrate 300 is, for example, lithium niobate, lithium tantalate, aluminum nitride, zinc oxide, etc., and the surface of the piezoelectric material substrate 300 opposite to the substrate 100 is provided with a The second adhesive film layer 210 includes an interdigitated structure above the piezoelectric material substrate 300, and the material of the interdigitated structure is, for example, aluminum, titanium, copper, chromium, silver, etc. or a combination thereof.

[0029] Spec...

Embodiment 2

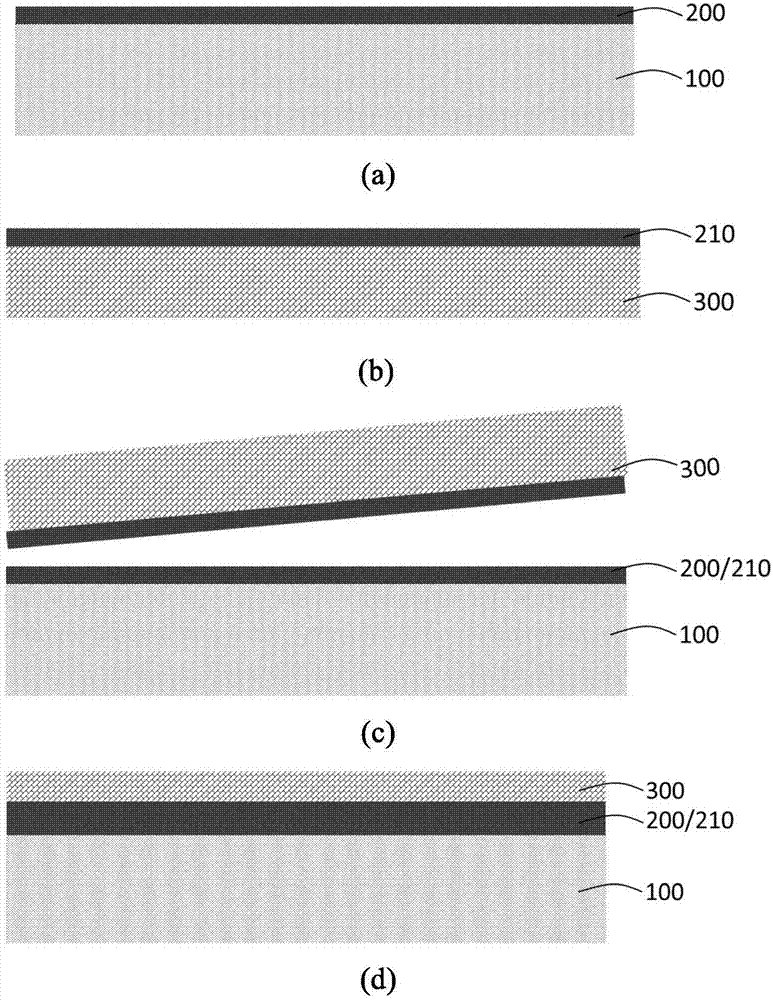

[0034] figure 2 It is a flow chart of the preparation process of the temperature-compensated surface acoustic wave resonator of the present invention. like figure 2 As shown, the present invention also proposes a method for preparing the temperature-compensated surface acoustic wave resonator used in Example 1, the preparation method comprising the following steps:

[0035] (a) Prepare a substrate 100 polished on one or both sides, with the polished side up, for standard cleaning. Then deposit a layer of adhesive material on the surface of the silicon wafer to form a first adhesive film layer 200 , the material of the first adhesive film layer 200 can be, for example, silicon dioxide, silicon oxynitride and the like. like figure 2 (a) shown.

[0036] (b) Deposit a layer of adhesive film material on the piezoelectric material substrate 300 to form the second adhesive film layer 210, the deposition process of the second adhesive film layer 210 is the same as that of the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com