Method for preparing pure physical refined oil and camellia oleifera seed oil by using three-stage molecular distillation

A technology of molecular distillation and camellia seed oil, which is applied in the field of physical refining technology of camellia seed oil, can solve the problems of high working temperature, uneconomical, low processing capacity, etc., and can reduce peroxide value, improve safety, and remove pigment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

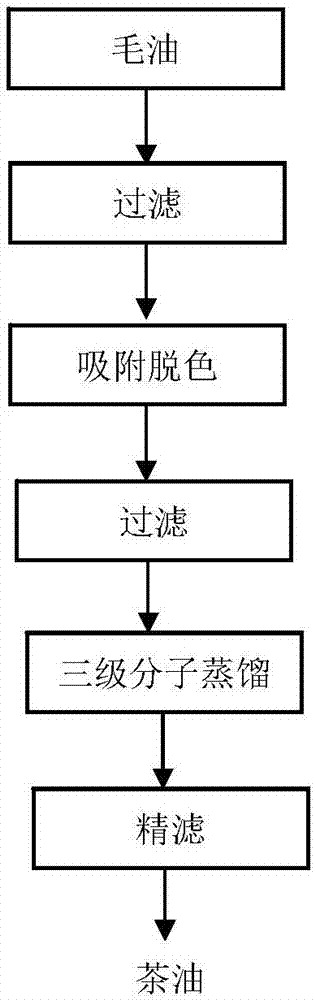

[0020] Embodiment 1: Utilize three-stage molecular distillation to prepare the method for pure physical refining camellia oleifera seed oil:

[0021] (1) In the decolorization tank, heat camellia seed oil to 110°C through steam insulation, then add 3% (w / w) mixed adsorbent (activated clay: self-made adsorbent = 3:1), according to the stirring speed 50r / min, heating time 30min to decolorize under near vacuum conditions, and then filter through a 200-mesh bag filter while hot to obtain decolorized oil. In the present invention, the temperature of crude oil heated by steam insulation is usually 50-120°C, for example, 50°C, 60°C, 70°C, 80°C, 90°C, 100°C, 11°C, or 120°C. The addition amount of mixed adsorbent in the present invention is usually 0.1~8% (w / w), for example can be 0.1%, 0.2%, 0.3%, 0.4%, 0.5%, 0.6%, 0.7%, 0.8%, 0.9% , 1%, 2%, 3%, 4%, 5%, 6%, 7%, 8%. In the present invention, the stirring speed is usually 30-100r / min, for example, 30r / min, 40r / min, 50r / min, 60r / min, 7...

Embodiment 2

[0030] Embodiment 2: Utilize three-stage molecular distillation to prepare the method for pure physical refining camellia oleifera seed oil:

[0031] (1) In the decolorization tank, heat camellia seed oil to 100°C through steam insulation, then add 1.5% (w / w) mixed adsorbent (activated clay: self-made adsorbent = 2:1), according to the stirring speed 50r / min, heating time 30min to decolorize under near-vacuum conditions, and then filter through a 200-mesh bag filter while hot to obtain decolorized oil.

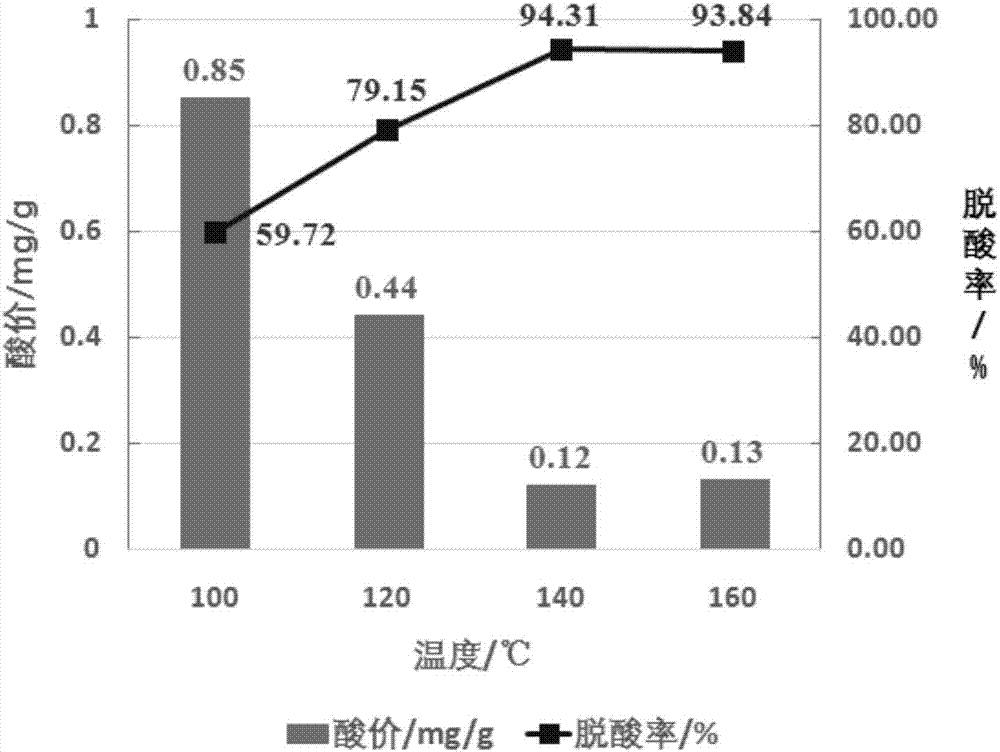

[0032] (2) The decolorized oil is deacidified by three-stage molecular distillation. The working conditions of the first-stage molecular distillation are temperature 110°C, the temperature of the condensation surface is 30°C, and the pressure is 900Pa; the working conditions of the second-stage molecular distillation are temperature 160°C and the temperature of the condensation surface 30°C, pressure 50Pa; the working conditions of the third stage molecular distillation are te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peroxide value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com