Test device and method for simulating corrosion of hollow copper conductor of generator in inner cooling water

A test device and technology of copper wires, applied in the field of test devices for simulating the corrosion of hollow copper wires of generators in internal cooling water, can solve problems affecting copper corrosion, difficulty in obtaining accurate and effective test data, etc., and achieve accurate and reliable tests The effect of data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

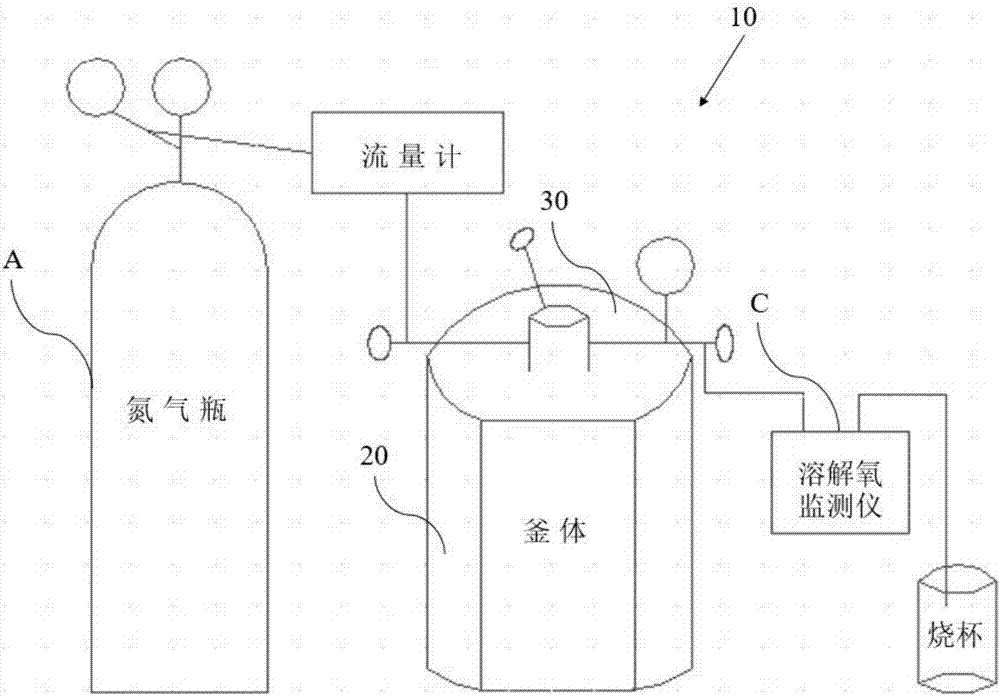

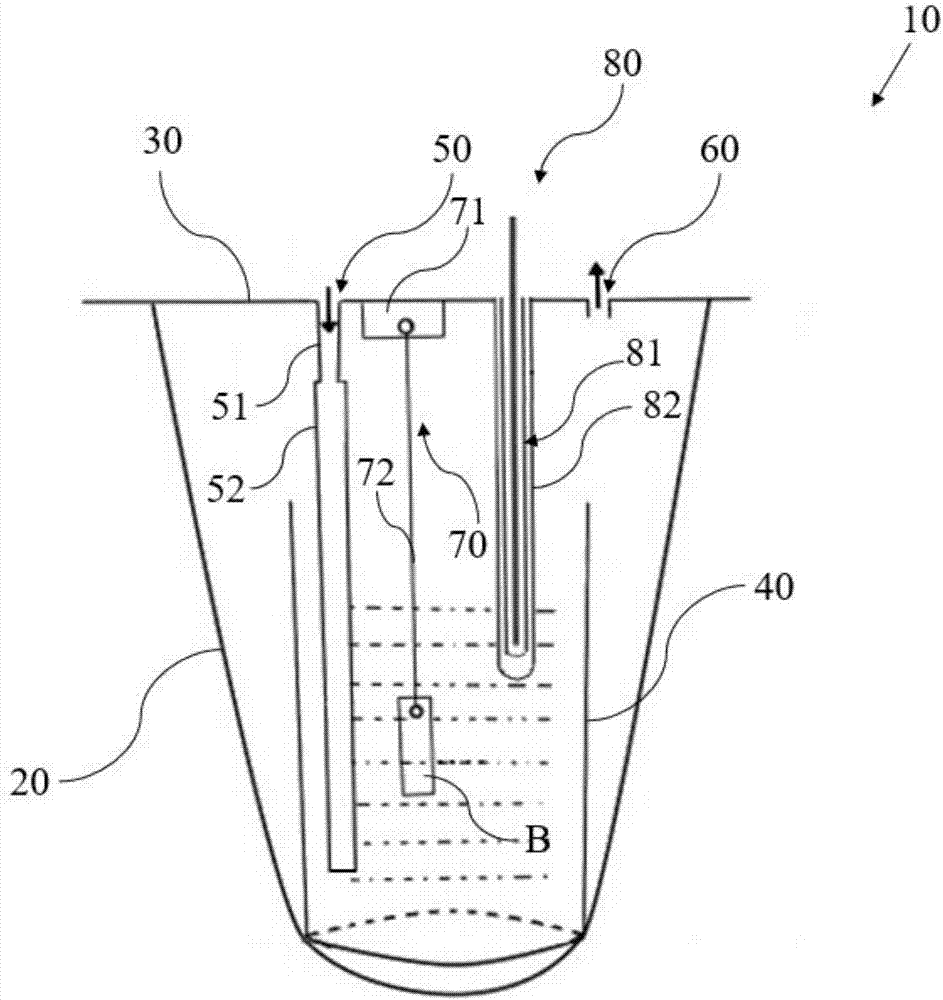

[0052] The test device and corresponding test method for simulating the corrosion of the inner cooling water of the hollow copper wire of the generator involved in the present invention will be described in detail below with reference to the accompanying drawings.

[0053]

[0054] like figure 1 and 2 As shown, in the present embodiment, the test device 10 for simulating the corrosion of the hollow copper wire of a generator in internal cooling water includes: a kettle body 20, a kettle cover 30, a wide-mouth glass bottle 40, an air inlet 50, an air outlet 60, a test Sheet hanging part 70, and temperature control part 80.

[0055] The kettle cover 30 is hermetically closed on the kettle body 20 .

[0056] The wide-mouth glass bottle 40 is arranged in the kettle body 30 for containing desalted water. The wide-mouth glass bottle 40 is arranged close to the kettle body 30 and has a volume of about 1 / 3 of the volume of the kettle body 30 .

[0057] The air inlet 50 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com