Gold-modified phosphorus-doped carbon nitride composite material modified titanium dioxide photoelectrode and preparation method and application thereof

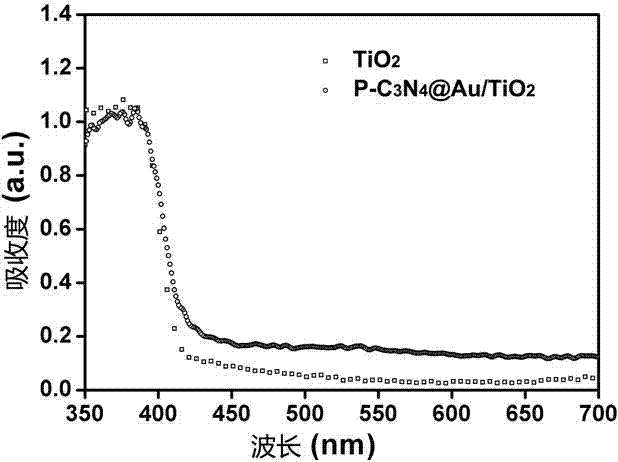

A composite material and photoelectrode technology, which is applied in the direction of electrodes, electrolytic processes, electrolytic components, etc., can solve the problems of low solar conversion efficiency and limit the application of TiO, so as to broaden the spectrum absorption range, improve separation and transfer efficiency, and enhance absorption intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A P-C 3 N 4 @Au modified TiO 2 A method for preparing a photoelectrode, comprising the steps of:

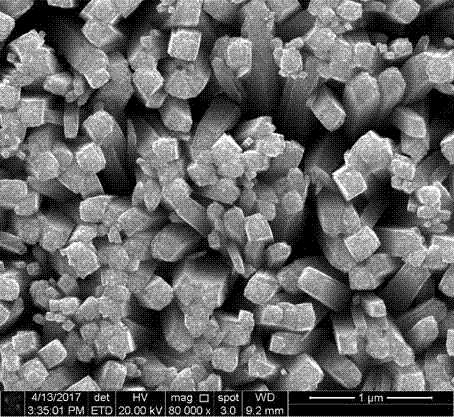

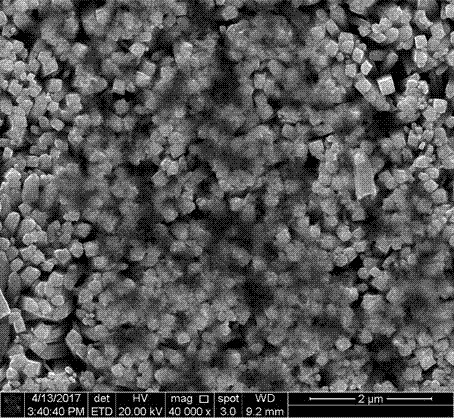

[0034] (1) Growth of TiO on FTO conductive glass substrate 2 Nano stave

[0035] A titanium source compound was added to hydrochloric acid with a mass fraction of 18.5%, and stirred at room temperature until the solution was clear to obtain a mixed solution; the titanium source compound was isopropyl titanate, and the volume ratio of hydrochloric acid to titanium source compound was 3:0.06. Firstly, the obtained mixed solution was transferred to a tetrafluoroethylene-lined reactor, and then the cleaned FTO conductive glass was placed in the reactor leaning downwards. The hydrothermal reaction was carried out at 150°C for 12 hours, and then the temperature was naturally lowered to room temperature. The FTO conductive glass obtained after the hydrothermal reaction was taken out, washed with ultrapure water, and high-purity N 2 blow dry. Then put it into a muffle furnac...

Embodiment 2

[0045] A P-C 3 N 4 @Au modified TiO 2 A method for preparing a photoelectrode, comprising the steps of:

[0046] (1) Growth of TiO on FTO conductive glass substrate 2 Nano stave

[0047] Add a titanium source compound to hydrochloric acid with a mass fraction of 15%, and stir at room temperature until the solution is clear to obtain a mixed solution; the titanium source compound is isopropyl titanate, and the volume ratio of hydrochloric acid to titanium source compound is 3:0.06. Firstly, the obtained mixed solution was transferred to a tetrafluoroethylene-lined reactor, and then the cleaned FTO conductive glass was placed in the reactor leaning downwards. After hydrothermal reaction at 140°C for 12 h, the temperature was naturally lowered to room temperature, and the FTO conductive glass obtained after the hydrothermal reaction was taken out, washed with ultrapure water, and high-purity N 2 blow dry. Then put it into a muffle furnace and raise the temperature to 400 °C...

Embodiment 3

[0055] A P-C 3 N 4 @Au modified TiO 2 A method for preparing a photoelectrode, comprising the steps of:

[0056] (1) Growth of TiO on FTO conductive glass substrate 2 Nano stave

[0057] Add a titanium source compound to hydrochloric acid with a mass fraction of 20%, and stir at room temperature until the solution is clear to obtain a mixed solution; the titanium source compound is n-butyl titanate, and the volume ratio of hydrochloric acid to titanium source compound is 3:0.07. Firstly, the obtained mixed solution was transferred to a tetrafluoroethylene-lined reaction kettle, and then the cleaned FTO glass was placed in the reaction kettle with the conductive surface facing down. The hydrothermal reaction was carried out at 160°C for 6 hours, and then the temperature was naturally lowered to room temperature. The FTO conductive glass obtained after the hydrothermal reaction was taken out, washed with ultrapure water, and the high-purity N 2 blow dry. Then put it into a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com