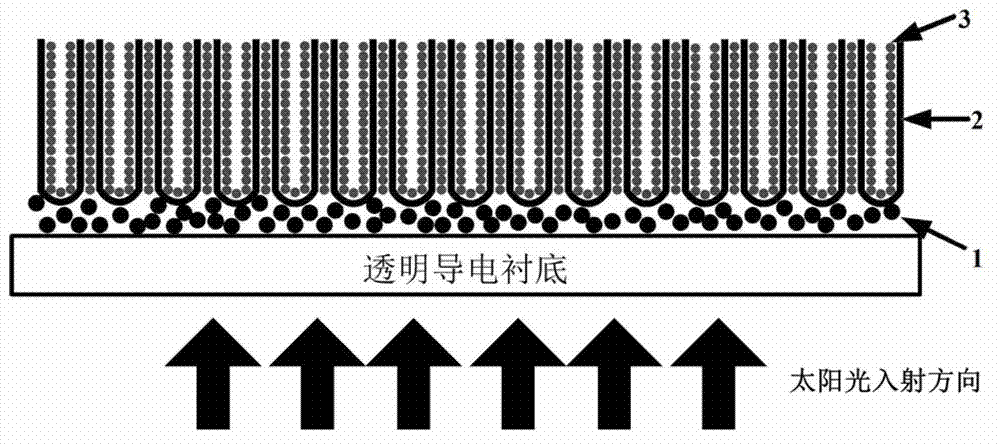

Method for preparing transparent electrode based on titanium dioxide nanotubes

A titanium dioxide and transparent electrode technology is applied in the field of preparation of transparent electrodes based on titanium dioxide nanotubes, which can solve the problems of reduced quality, cumbersome steps, low film quality and the like, and achieves the effects of increasing annealing temperature, expanding absorption range and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment includes the following steps:

[0033] Step 1, using an anodic oxidation method to grow a layer of titanium dioxide nanotubes on the titanium metal substrate;

[0034] Preferably, in step 1, the titanium dioxide nanotubes formed by anodic oxidation can also be annealed at a temperature greater than 0 degrees and less than or equal to 400 degrees to form an amorphous titanium dioxide nanotube structure less than 300 degrees or a crystalline titanium dioxide nanotube structure greater than 300 degrees. Thickness of 500 nanometers to 50 microns;

[0035] Specifically:

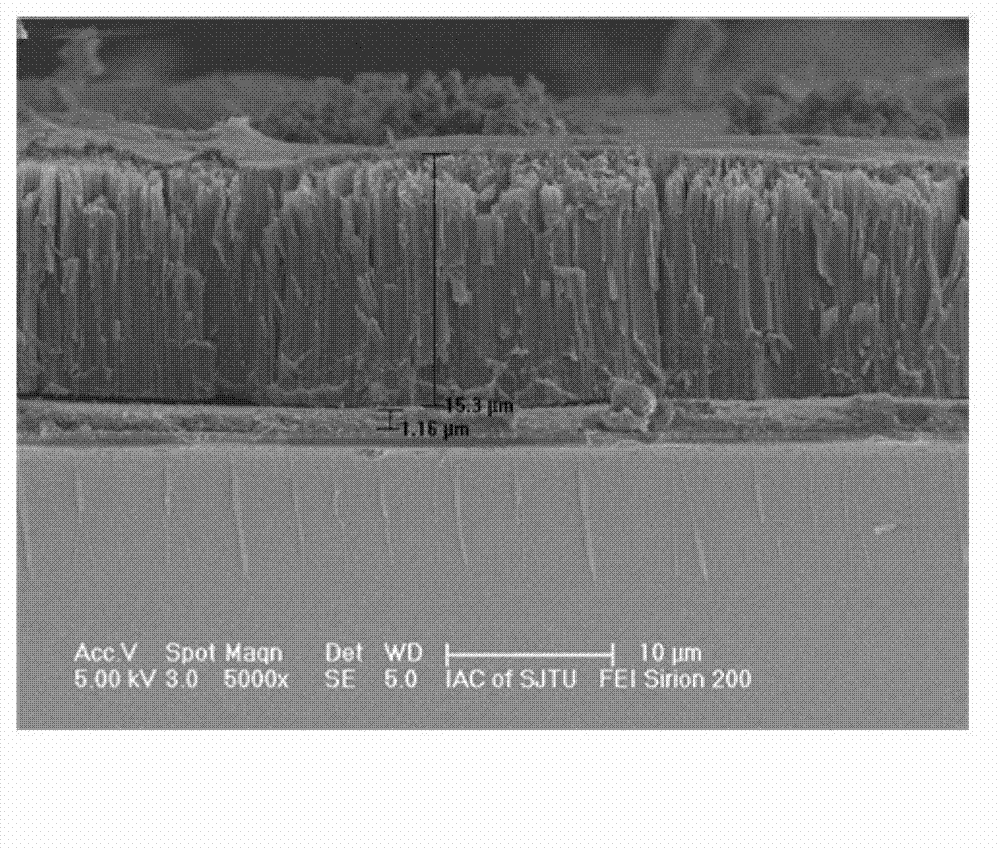

[0036] (1) A titanium dioxide nanotube layer about 15 microns thick is grown on a titanium metal sheet with a purity of 99.6% and a thickness of 1 mm by anodic oxidation. The electrolyte system is an ethylene glycol solution containing 0.5% by mass fraction of ammonium fluoride and 3% by volume of deionized water. The anodic oxidation voltage is 60 volts, provided by a constant voltage sou...

Embodiment 2

[0058] Implementation 2 is a modification of Example 1.

[0059] The difference between this example and Example 1 is that step (1) in step 2 is: peel off the sample after annealing at 350 degrees by re-anodizing, anodize again in the above electrolyte, and the anodizing voltage Still at 60 volts, the duration is 1 hour, and the temperature of the electrolyte is 30 degrees.

Embodiment 3

[0061] Embodiment 3 is a modification example of Embodiment 1.

[0062] The difference between this embodiment and Example 1 is that step 2 (3) is to anneal the peeled titanium dioxide nanotube film, and gently place the obtained crystalline titanium dioxide nanotube film on a flat surface with tweezers. On the ceramic sheet, the annealing process is carried out in air, the annealing temperature is 550 degrees, the heating and cooling rate is 3 degrees per minute, and the holding time is 2 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com