Organic-inorganic compound chlorinated natural rubber emulsion and preparation method thereof

A technology of chlorinated natural rubber and inorganic composites, which is applied in the direction of rubber derivative coatings, coatings, anti-corrosion coatings, etc., can solve the problems of unstable emulsion performance, low degree of emulsion polymerization reaction, difficulty in initiating emulsion polymerization reaction, etc., to achieve Good anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

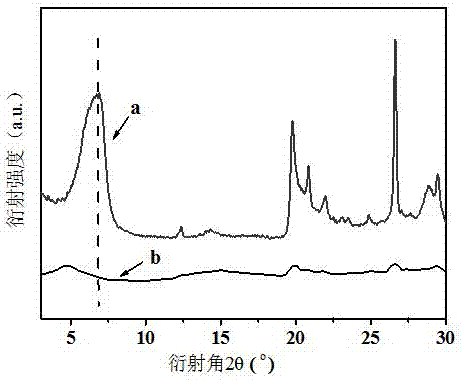

[0037] (1) Preparation of chlorinated natural rubber-montmorillonite organic-inorganic composite; mix sodium-based montmorillonite and CR5 chlorinated natural rubber uniformly, and then add to the mixture of sodium-based montmorillonite and chlorinated natural rubber Stir a small amount of water to form a paste. The weight ratio of chlorinated natural rubber, sodium-based montmorillonite and water is 1:0.16:0.83; o Squeeze 3 times under C, 25 o After C is air-dried, chlorinated natural rubber-montmorillonite organic-inorganic composite is obtained;

[0038] (2) Mix the chlorinated natural rubber-montmorillonite organic-inorganic composite obtained in step (1) with water, 26 o Stir at C to form a slurry, wherein the weight ratio of chlorinated natural rubber-montmorillonite organic-inorganic composite to water is 1:5;

[0039] (3) Mix styrene, methyl acrylate and the slurry obtained in step (2), and then mix it in 25 o Under C, stir at 500 rpm for 20 minutes to obtain an emulsion, wh...

Embodiment 2

[0044] (1) Preparation of chlorinated natural rubber-montmorillonite organic-inorganic composite; mix sodium-based montmorillonite and CR10 chlorinated natural rubber uniformly, and then add to the mixture of sodium-based montmorillonite and chlorinated natural rubber Stir a small amount of water evenly into a paste. The weight ratio of chlorinated natural rubber, sodium-based montmorillonite and water is 1:0.33:2.5; o Squeeze 6 times under C, 25 o After C is air-dried, chlorinated natural rubber-montmorillonite organic-inorganic composite is obtained;

[0045] (2) Mix the chlorinated natural rubber-montmorillonite organic-inorganic composite obtained in step (1) with water, 25 o Stir at C to form a slurry, in which the weight ratio of chlorinated natural rubber-montmorillonite organic-inorganic composite to water is 1:5.3;

[0046] (3) Mix styrene, methyl acrylate and the slurry obtained in step (2), and then mix it in 26 o Under C, stir at 600 rpm for 35 minutes to obtain an emuls...

Embodiment 3

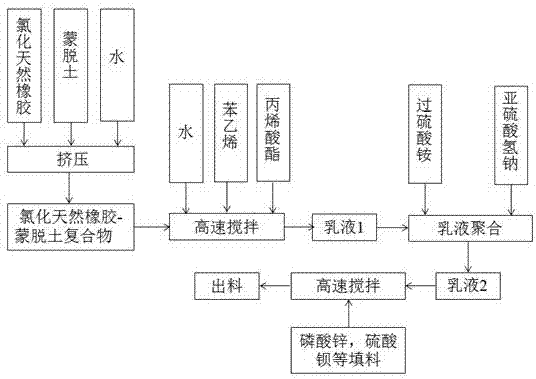

[0051] Such as figure 2 As shown, the preparation method of the present invention is as follows:

[0052] (1) Preparation of chlorinated natural rubber-montmorillonite organic-inorganic composite; mix sodium-based montmorillonite and CR10 chlorinated natural rubber uniformly, and then add to the mixture of sodium-based montmorillonite and chlorinated natural rubber Stir a small amount of water evenly into a paste. The weight ratio of chlorinated natural rubber, sodium-based montmorillonite and water is 1:0.5:4.17; o Squeeze 9 times under C, 26 o After C is air-dried, the chlorinated natural rubber-montmorillonite layer embedded composite is obtained;

[0053] (2) Mix the chlorinated natural rubber-montmorillonite organic-inorganic composite obtained in step (1) with water, 25 o Stir at C to form a slurry, in which the weight ratio of chlorinated natural rubber-montmorillonite organic-inorganic composite to water is 1:5.5;

[0054] (3) Mix styrene, ethyl acrylate and the slurry obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com