Electrostatic spinning micro-nanofiber/clay aerogel composite material and preparation method thereof

A technology of micro-nano fiber and composite material, which is applied in the field of electrospinning micro-nano fiber/clay airgel composite material and its preparation, can solve problems such as environmental impact, and achieve simple preparation process, low thermal conductivity, and good biocompatibility sex and degradability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

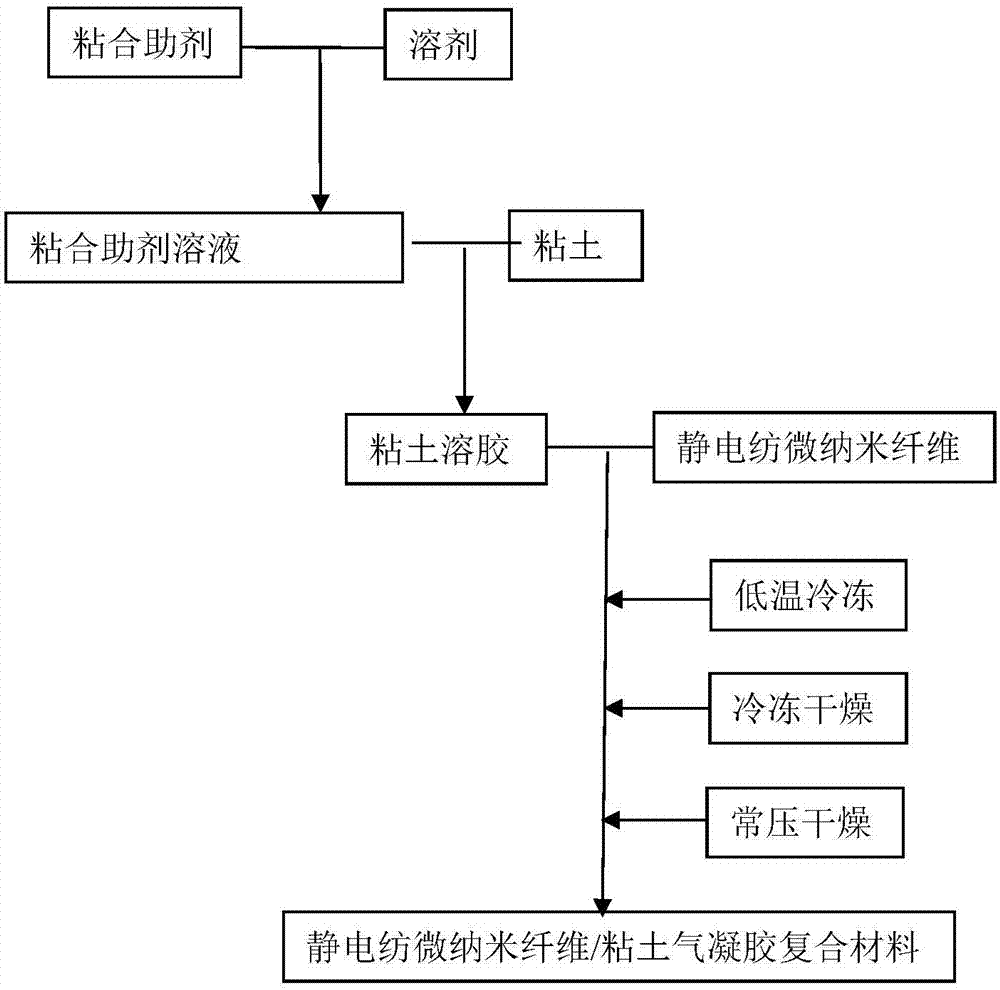

Method used

Image

Examples

example 1

[0038] In this example, the airgel composite material containing electrospun micro-nano fibers and clay is prepared by using polyvinyl alcohol as an adhesive aid, and electrospun micro-nano fibers and montmorillonite as raw materials. The preparation steps are as follows:

[0039] (1) Add PVDF (polyvinylidene fluoride) particles to DMF (N,N-dimethylformamide solvent), wherein the mass concentration of PVDF is 25%, and stir in a constant temperature water bath at 120°C until PVDF is completely dissolved;

[0040] (2) Using an electrospinning device, the spinning process parameters are: injection speed 0.03-0.04mm / min, voltage 12kV, drum receiver distance 15cm, drum running line speed 4m / min, injector lateral movement speed 12cm / min;

[0041] (3) Inject the mixed solution of PVDF and DMF into the syringe, fix it on the metering pump for spinning, and obtain the electrospun micro-nano fiber and accumulate the electrospun micro-nano fiber to form an electrospun nano-fiber felt, and...

example 2

[0049] In this example, the electrospun micro-nanofiber / clay airgel composite material is prepared by using pectin as an adhesive aid, and the electrospun micro-nanofiber and montmorillonite airgel are composited. The preparation steps are as follows:

[0050] (1) Add PVDF (polyvinylidene fluoride) particles to DMF (N,N-dimethylformamide solvent), wherein the mass concentration of PVDF is 25%, and stir in a constant temperature water bath at 120°C until PVDF is completely dissolved;

[0051] (2) Using an electrospinning device, the spinning process parameters are: injection speed 0.03-0.04mm / min, voltage 12kV, drum receiver distance 15cm, drum running line speed 4m / min, injector lateral movement speed 12cm / min;

[0052] (3) Inject the mixed solution of PVDF and DMF into the syringe, fix it on the metering pump for spinning, and obtain the electrospun micro-nano fiber and accumulate the electrospun micro-nano fiber to form an electrospun nano-fiber felt, and then remove it from ...

example 3

[0060] In this example, the electrospun micro-nanofiber / clay airgel composite material is prepared by using casein as an adhesion aid, and the electrospun micro-nanofiber and montmorillonite airgel are composited. The preparation steps are as follows:

[0061] (1) Add PVDF (polyvinylidene fluoride) particles to DMF (N,N-dimethylformamide solvent), wherein the mass concentration of PVDF is 25%, and stir in a constant temperature water bath at 120°C until PVDF is completely dissolved;

[0062] (2) Using an electrospinning device, the spinning process parameters are: injection speed 0.03-0.04mm / min, voltage 12kV, drum receiver distance 15cm, drum running line speed 4m / min, injector lateral movement speed 12cm / min;

[0063] (3) Inject the mixed solution of PVDF and DMF into the syringe, fix it on the metering pump for spinning, and obtain the electrospun micro-nano fiber and accumulate the electrospun micro-nano fiber to form an electrospun nano-fiber felt, and then remove it from ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com