A device and method for treating ammonia nitrogen wastewater

A technology for ammonia nitrogen wastewater and raw water, applied in the direction of microorganism-based methods, biomass post-treatment, chemical instruments and methods, etc., can solve the problems of affecting the internal structure of the pellets, decreasing the strength of the pellets, and long processing time, etc., so as to reduce the operation Effects of difficulty, reduced operation, and fast removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

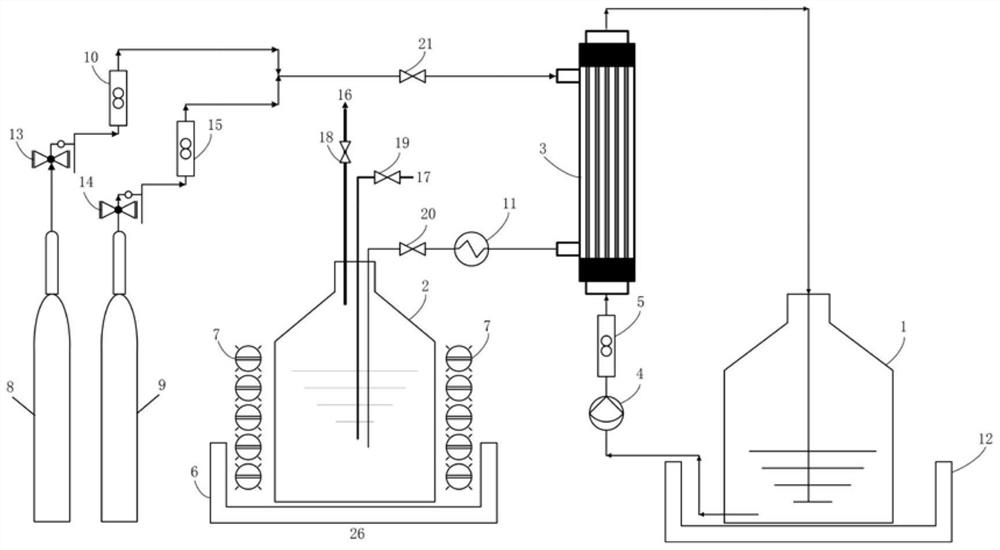

Method used

Image

Examples

Embodiment example

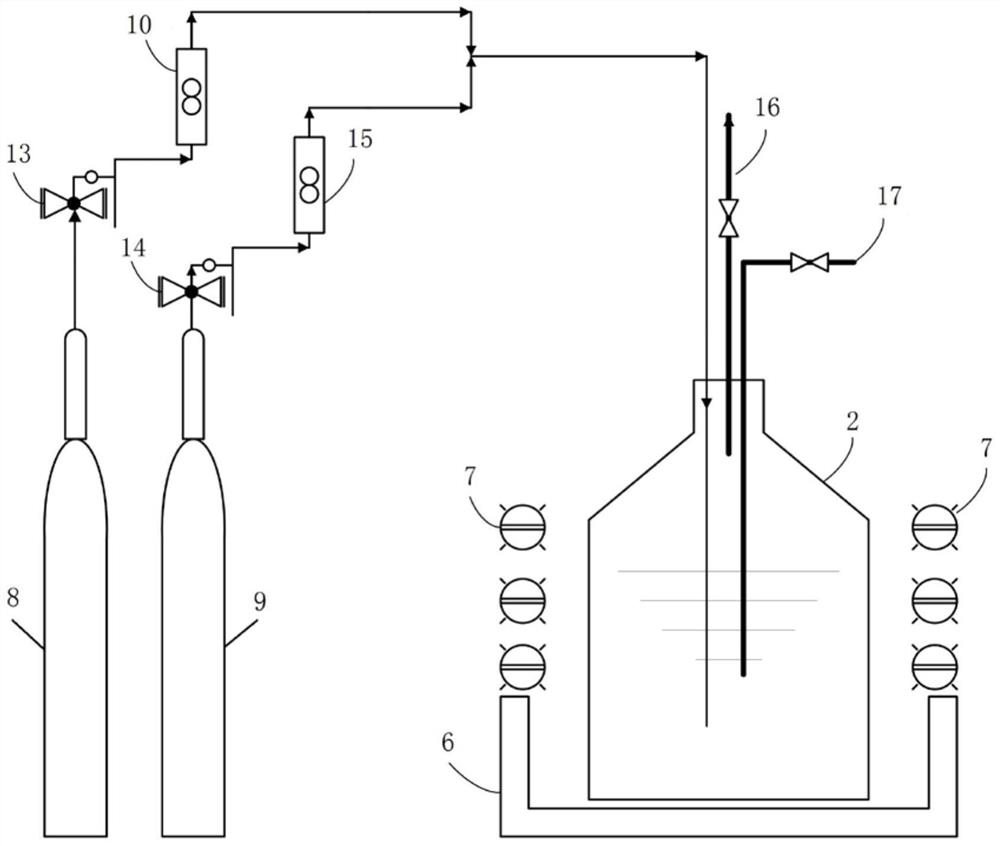

[0072] 1. Materials

[0073] Microalgae strains and culture conditions: select a single colony of Chlorella vulgaris growing on the surface of the agar dish 23, and transfer the microalgae colony to the culture solution prepared in advance and sterilized by a high-pressure steam sterilizer.

[0074] The culture medium is 3N-BBM+V culture medium, in which 0.2g / L glucose is added, and the formula of 3N-BBM+V culture medium is as follows (concentrations are all g / L): NaNO 3 ,0.75; CaCl 2 2H 2 O,0.025; MgSO 4 ·7H 2 O,0.075;K 2 HPO 4 ·3H 2 O,0.075; KH 2 PO 4 , 0.175; NaCl, 0.025. In addition, the culture fluid also contains other trace components, including (concentrations are mg / L): Na 2 EDTA, 4.5; FeCl 3 ·6H 2 O,0.582; MnCl 2 4H 2 O,0.246; ZnCl 2 ,0.03; CoCl 2 ·6H 2 O, 0.012; Na 2 MoO 4 2H 2 O,0.024; VB 1 ,1.2; VB 12 ,0.01. The culture volume is 20 mL, and the culture solution is placed in a 25 ml flask 24 .

[0075] The culture solution containing Chlorel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com