Manufacturing equipment and manufacturing method of metal and nonmetal composite additive

A manufacturing equipment and non-metal technology, which is applied in the field of metal and non-metal composite additive manufacturing devices, can solve the problems of inability to realize metal and non-metal composite printing, large difference in melting point, and inability to composite printing, etc. Fast print speed and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

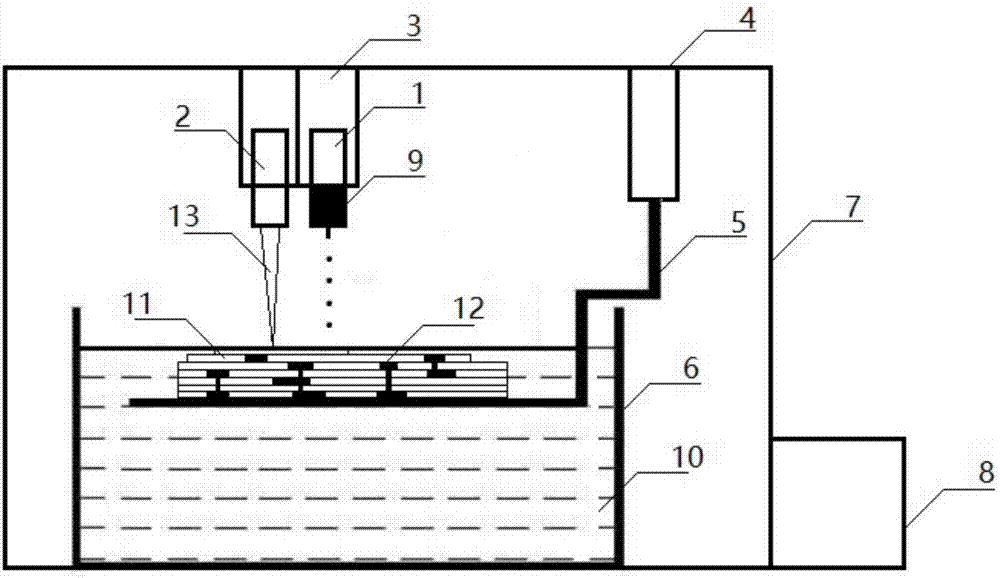

[0050] Such as figure 1 As shown, the metal and non-metal composite additive manufacturing equipment provided by the present invention includes a liquid metal inkjet device 1, a light emitter 2, a multi-axis moving device 3, a lifting device 4, a printing platform 5, a light curing material tank 6, Frame 7 and control system 8.

[0051] The liquid metal inkjet device 1 is used to eject liquid metal droplets, fixed on the multi-axis moving device 3, and can move horizontally with the multi-axis moving device 3 to any position within the printing platform 5; the liquid metal inkjet device 1 is specially designed Liquid metal inkjet valve (prepared according to patent CN106623940A);

[0052] The light emitter 2 is fixed on the multi-axis moving device 3 and can move to any position above the printing platform 5 with the multi-axis moving device 3; the light emitter 2 has multiple light-emitting units, and the light-emitting unit uses Thorlabs laser diode L405P20, using 64 The light-e...

Embodiment 2

[0064] Using the equipment of embodiment 1, the printing method of composite additive is:

[0065] S1. The printed file is transmitted to the control system, and the control system completes the slicing design of the metal layer and the non-metal layer. The number of slices of the two materials is the same, and the thickness of the single layer is 0.01mm-1mm;

[0066] S2. The control system controls the lifting device to move the printing platform above the light-curing material tank, and the surface of the printing platform is not submerged by the light-curing material;

[0067] S3. The control system controls the multi-axis moving device to make the liquid metal inkjet device move according to the slicing design of the metal layer, and the control system controls the liquid metal inkjet device to spray metal droplets on the printing platform to form a metal layer structure;

[0068] S4. The control system controls the lifting device to move the printing platform down by one layer, so...

Embodiment 3

[0073] The equipment used in this embodiment is basically the same as that in Embodiment 1. For the sake of brevity of description, in the description of this embodiment, the same technical features as in Embodiment 1 will not be described, and only the differences between this embodiment and Embodiment 1 will be explained. Office:

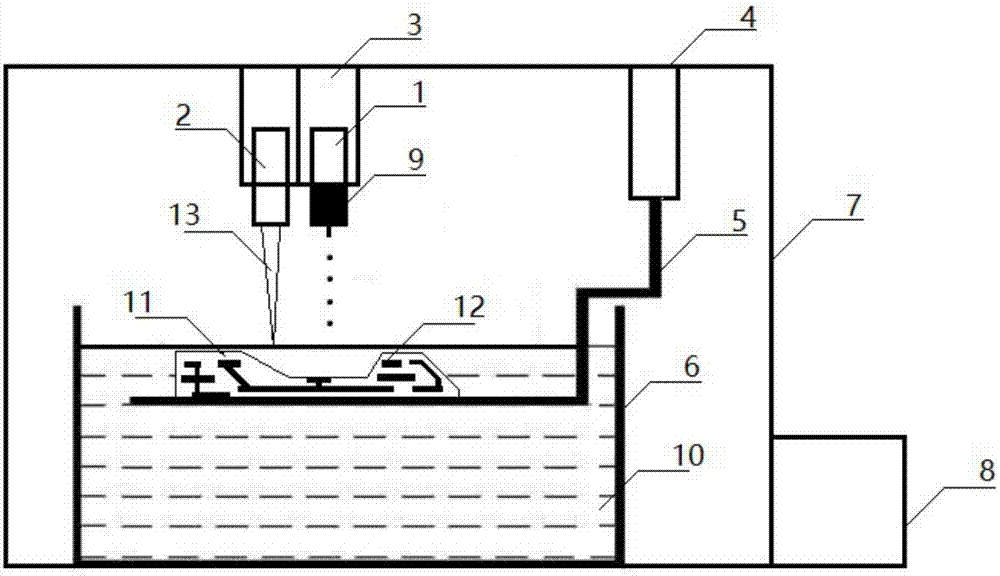

[0074] Such as figure 2 As shown, the liquid metal inkjet device 1 used in this embodiment is a striker-type liquid metal inkjet valve, which includes a heating cavity, an insulated push rod, a micro nozzle, a feedback control system, an ink recovery system and other components. The transmitter 2 is a focused ultraviolet laser transmitter (using a laser diode in the ultraviolet band and a lens). This embodiment is the printing of a special-shaped structure circuit, that is, the size and structure of the printed structure layer and the layer are inconsistent.

[0075] The pre-printing preparation process is the same as in Example 1. The metal layer an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com