Shark's Metal Magnetic Line Marker Making Device

A metal magnetic and device-making technology, applied in fish farming, biocide-containing paints, applications, etc., can solve problems such as the large influence of fish activities and the clarity of the line marking and serial number, and achieve clear marking serial number and rough surface. The accuracy and accuracy will not be reduced, and the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

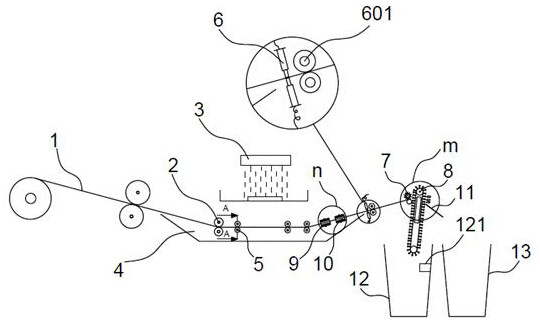

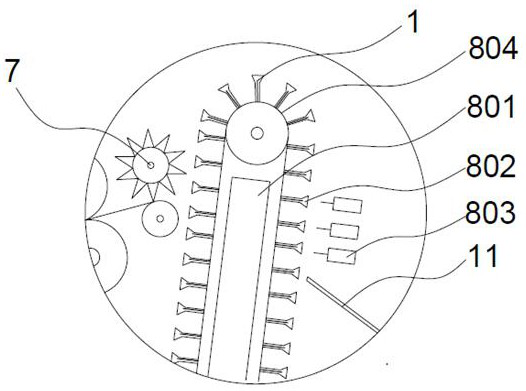

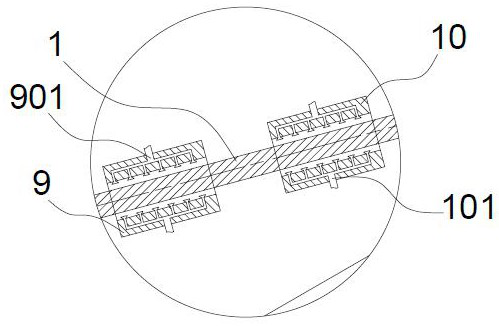

[0028] Such as Figure 1~8 As shown, the Shark’s metal magnetic wire marking manufacturing device includes an etching machine 3 capable of etching the wire marking body 1, and the etching machine 3 is connected with a drilling pin group capable of drilling the tail end of the segmented wire marking body 1 8. An etching tank 4 is provided under the etching machine 3, and at least one set of guide wheels 2 is provided in the etching tank 4. Through the guide set wheels 2, the line standard body 1 can be guided into the etching tank 4, and the guide wheel set 2 exits One side is provided with three groups of shaping wheel groups 5 at least, and shaping wheel group 5 is made up of concave round wheel 501 and shaping wheel 502, and concave round wheel 501 and shaping wheel 502 are provided with the semicircular arc surface corresponding to line standard body 1, shaping wheel The bottom surface of the semi-arc surface of 502 is also provided with a concave ring, the width of the con...

Embodiment 2

[0031] When the metal magnetic wire mark manufacturing device for sharks of the present invention is actually working: the wire mark body 1 manufactured by the present invention initially adopts a cylindrical wire rod to be transmitted to the guide wheel group 2 through the transmission wheel group, and then guides the wire rod into the etching groove 4, Before the wire enters the attachment of the etching beam area under the etching machine 3, the round wire is extruded into a rectangle by multiple sets of qualitative wheel sets 5, so that the etching machine 3 can process the marking serial number on the rectangular surface, and the wire is initially formed after etching It is the line mark body 1, the line mark body 1 is sprayed with anti-rust liquid by the spraying machine 9, and then dried by the dryer 10, and then the surface of the line mark body 1 is coated with a layer of rubber by the glue dispenser 6, and the transmission wheel group 601 Linear extrusion of the rubbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com