Preparation method of high-strength flexible graphene foam body

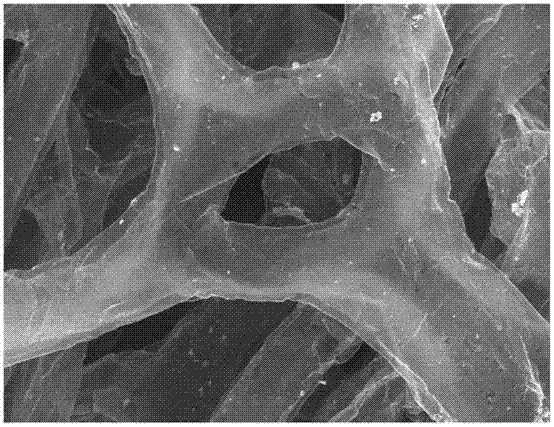

A flexible graphite, high-strength technology, applied in graphene, nano-carbon and other directions, can solve the problems of insufficient mechanical strength and performance degradation of three-dimensional graphene, and achieve the effect of large-scale production, low production cost and few processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A kind of preparation method of high strength flexible graphene foam body, it is characterized in that the concrete steps of described method are as follows:

[0035] (1) Metal foam surface treatment

[0036] The metal foam has a bulk density of 0.8g / cm 3 , nickel foam with a thickness of 1mm;

[0037] ① Soak the nickel foam completely in 0.1M dilute hydrochloric acid, and ultrasonically clean it for 10 minutes under the condition of ultrasonic power of 70W to remove the oxide on the surface;

[0038] ② Wash the nickel foam with deionized water for 10 minutes until the deionized water is neutral to completely remove residual hydrochloric acid;

[0039] ③Finally, wash the nickel foam with absolute ethanol for 10 minutes and let it dry in a cool place.

[0040] (2) Loading of carbon nano toughening agent

[0041] ① prepare the aqueous solution A of F127, the concentration of the surfactant in the solution A is 0.5g / L;

[0042] 2. Disperse the reduced graphene nanobel...

Embodiment 2

[0054] A kind of preparation method of high strength flexible graphene foam, with embodiment 1, wherein:

[0055] In the (1) step, the metal foam is iron foam with a thickness of 1mm and a bulk density of 0.5g / cm 3 ; The concentration of hydrochloric acid is 1M, wash for 3 minutes; wash with deionized water and absolute ethanol for 10 minutes respectively.

[0056] In the (2) step, the carbon nano toughening agent is an oxidized graphene nanoribbon with a width of 5nm and a length of 30um, and the dispersion concentration is 5.0g / L; the surfactant is SDBS, and the concentration is 5.0g / L. L.

[0057] In step (3), the constant temperature interval is 1070°C, and the thermal reduction time is 10 minutes; the inert gas is helium; the carbon source is acetylene, and the flow ratio during chemical vapor growth is C 2 h 2 :H 2 =3:20, CVD time is 10 minutes; cooling rate is 100°C / min.

[0058] In the (4) step, the etching solution is prepared according to the molar volume ratio ...

Embodiment 3

[0060] A kind of preparation method of high strength flexible graphene foam, with embodiment 1, wherein:

[0061] In step (1), the metal foam is copper foam with a thickness of 1mm and a bulk density of 0.8g / cm 3 ; Wash with 2M hydrochloric acid for 5 minutes under the condition of ultrasonic power of 60W; wash with deionized water and absolute ethanol for 10 minutes respectively.

[0062] In the (2) step, the carbon nano-toughening agent is a single-walled carbon nanotube with partial openings treated by a thermal acid method, with a width of 2nm and a length of 30um, and the concentration of the dispersion is 3.0g / L; the surface activity The agent is SDS, the concentration is 1.0g / L.

[0063] In the (3) step, the constant temperature interval is 1000 DEG C, and the thermal reduction time is 12 minutes; the inert gas is radon; the carbon source is ethylene, and the flow ratio C is during chemical vapor phase growth. 2 h 4 :H 2 =1:30, CVD time is 20 minutes; cooling rate i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com