Zinc base alloy and preparation method thereof

An alloy, zinc-based technology, applied in the field of zinc-based alloy and its preparation, can solve the problems of high impurity content, coarse grain structure of zinc-based alloy, environmental pollution, etc., and achieve the effect of ensuring personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

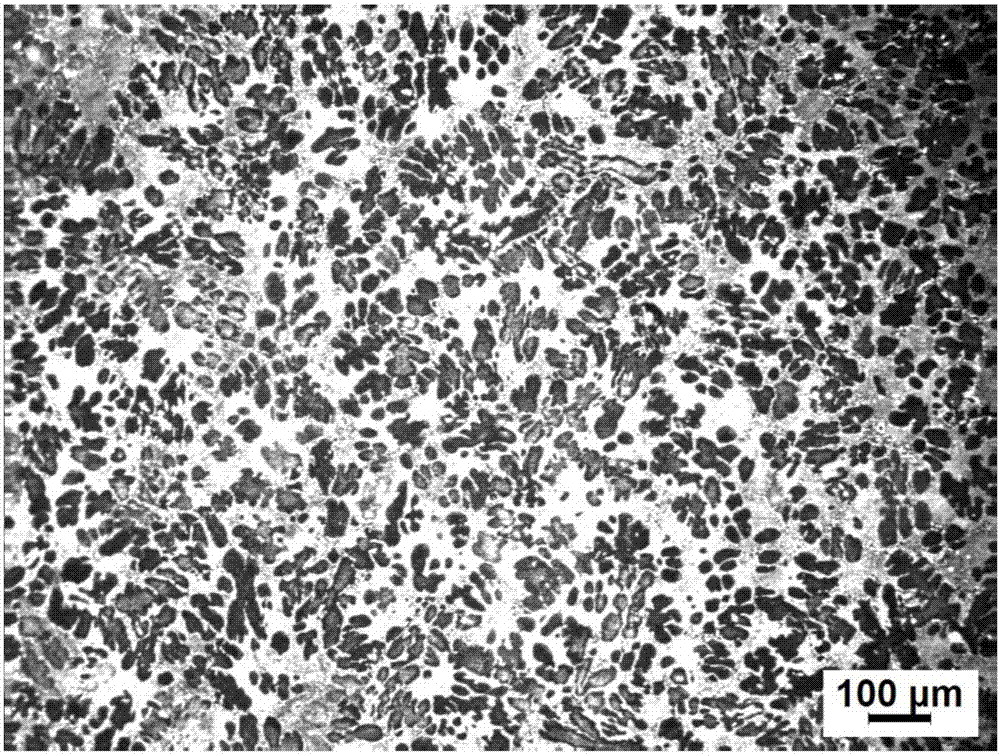

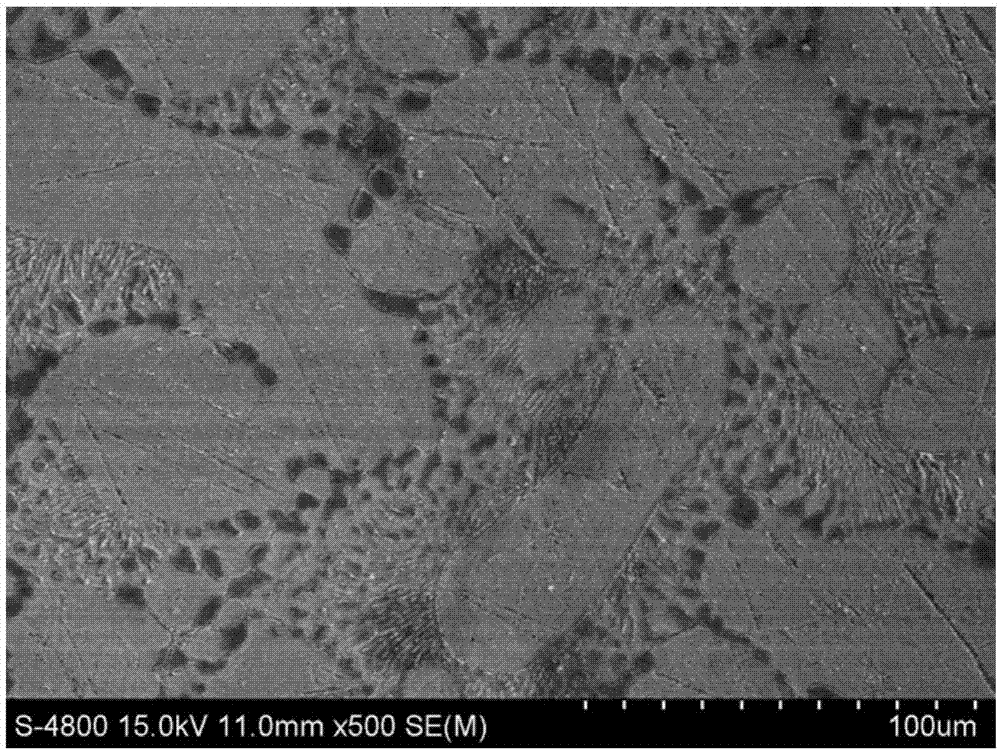

Image

Examples

Embodiment 1

[0033] The mass percentage of an element composition is: 5.5% Al, 2.5% Cu, 3.5% Ba, 0.011% Mg, 0.13% La, 0.22% Ce and the rest is Zn-Al-Cu-Ba-Mg-La-Ce Zinc-based alloy, the concrete steps of its preparation method are as follows:

[0034] The first step, the preparation of raw materials:

[0035] Process pure zinc ingots into blocks with a weight of 40-60g each, process aluminum-copper intermediate alloys with a mass percentage of copper of 50% into blocks with a weight of 5-15g each, and process pure barium ingot blocks into blocks with a weight of 1-10g each, processing pure aluminum ingots into blocks with a weight of 2-3g each, and processing aluminum-magnesium master alloys with a mass percentage of magnesium of 10% into blocks with a weight of 2-3g each block, put the above-mentioned pure zinc ingot block, aluminum-copper master alloy block, pure aluminum ingot block and aluminum-magnesium master alloy block into dilute nitric acid alcohol with a volume percentage concent...

Embodiment 2

[0046] The mass percentage of an element composition is: 7.5% Al, 4.5% Cu, 5.5% Ba, 0.016% Mg, 0.17% La, 0.29% Ce and the rest is Zn-Al-Cu-Ba-Mg-La-Ce Zinc-based alloy, the concrete steps of its preparation method are as follows:

[0047] The first step, the preparation of raw materials:

[0048] Process pure zinc ingots into blocks with a weight of 40-60g each, process aluminum-copper intermediate alloys with a mass percentage of copper of 50% into blocks with a weight of 5-15g each, and process pure barium ingot blocks into blocks with a weight of 1-10g each, processing pure aluminum ingots into blocks with a weight of 2-3g each, and processing aluminum-magnesium master alloys with a mass percentage of magnesium of 10% into blocks with a weight of 2-3g each block, put the above-mentioned pure zinc ingot block, aluminum-copper master alloy block, pure aluminum ingot block and aluminum-magnesium master alloy block into dilute nitric acid alcohol with a volume percentage conce...

Embodiment 3

[0054] The mass percentage of an element composition is: 5.5% Al, 4.5% Cu, 5.5% Ba, 0.016% Mg, 0.17% La, 0.29% Ce and the rest is Zn-Al-Cu-Ba-Mg-La-Ce Zinc-based alloy, the concrete steps of its preparation method are as follows:

[0055] The first step, the preparation of raw materials:

[0056] Process pure zinc ingots into blocks with a weight of 40-60g each, process aluminum-copper intermediate alloys with a mass percentage of copper of 50% into blocks with a weight of 5-15g each, and process pure barium ingot blocks into blocks with a weight of 1-10g each, processing pure aluminum ingots into blocks with a weight of 2-3g each, and processing aluminum-magnesium master alloys with a mass percentage of magnesium of 10% into blocks with a weight of 2-3g each block, put the above-mentioned pure zinc ingot block, aluminum-copper master alloy block, pure aluminum ingot block and aluminum-magnesium master alloy block into dilute nitric acid alcohol with a volume percentage conce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com