Method for continuous countercurrent ultrasonic extracting of coenzyme Q10

A countercurrent ultrasonic and coenzyme technology, applied in organic chemistry, quinone separation/purification, etc., can solve the problems of inability to reduce the amount of solvent, labor intensity, and extraction time. The effect of the leaching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 8

[0076] Example 8 Coenzyme Q10 Extraction

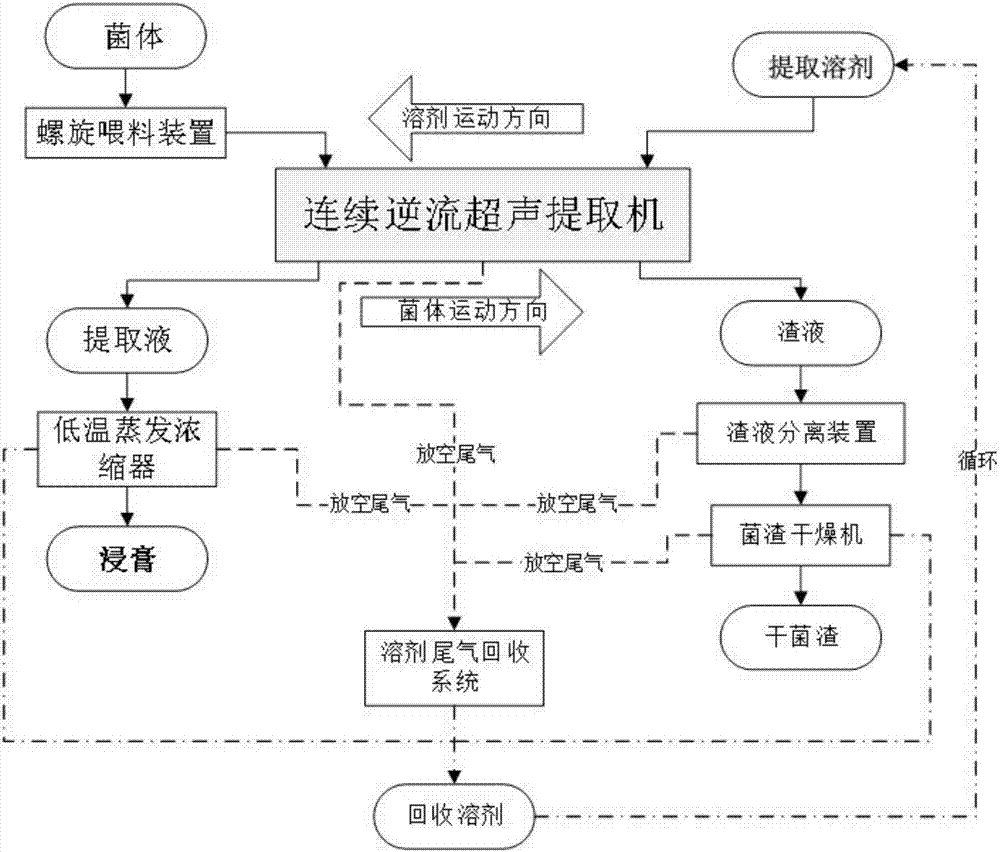

[0077] Get the fermentation thalline 1000kg of Rhodobacter sphaeroides, drop in with the feeding speed of 200kg / h from the feed inlet of continuous countercurrent ultrasonic extraction machine one end by screw feeding device, extraction solvent (10% ethyl acetate-90% n-heptane ) from the solvent inlet at the other end (the side close to the slag outlet) through the flowmeter at a feed rate of 1600L / h, and the bacteria slowly propelled toward the slag outlet under the action of the screw propeller, while the solvent It flows in the opposite direction of the cell movement, and the cell and the solvent fully contact in this countercurrent movement, thereby extracting the coenzyme Q10 in the cell. During the continuous countercurrent extraction process, the ultrasonic vibrator is turned on at the same time for auxiliary extraction, the ultrasonic frequency is 60KHZ, and the extraction temperature is controlled at 15°C. The extract is dis...

Embodiment 2

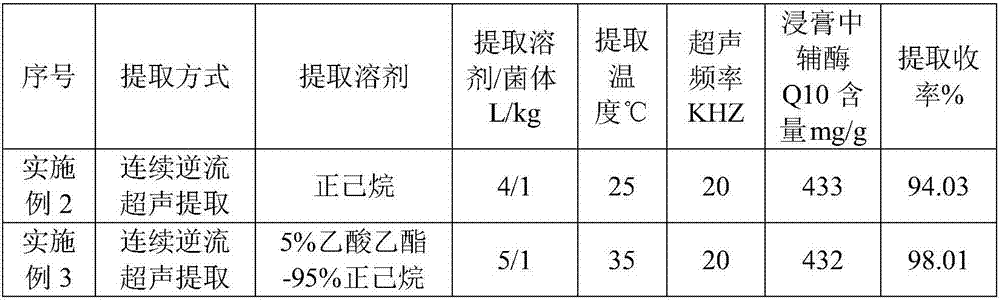

[0099] Embodiment 2 adopts the technical scheme of continuous countercurrent ultrasonic extraction of a low-polarity single solvent system, compared with Example 10, the extraction yield of Example 10 is obviously better than that of Example 2, indicating that the use of a mixed solvent system helps to improve the coenzyme Q10 The extraction yield;

[0100] Embodiments 6 and 9 adopt the technical scheme of continuous countercurrent ultrasonic extraction of a highly polar single solvent system, in contrast to Example 11, the content of coenzyme Q10 in the extract obtained in Example 11 is significantly higher than that of Examples 6 and 9, indicating that The use of a mixed solvent system helps to improve the quality of the extract of coenzyme Q10.

[0101] In summary, the technical solution of the present invention has the advantages of high extraction efficiency, high extraction rate of active ingredients, and small liquid output coefficient (the ratio of the input extraction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com