Graphene/metal/mgb2 composite material with high intercrystalline connectivity and preparation method

A composite material and connectivity technology, applied in the field of superconductivity, to achieve the effects of fine grain size, improved connectivity, and good connectivity between grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

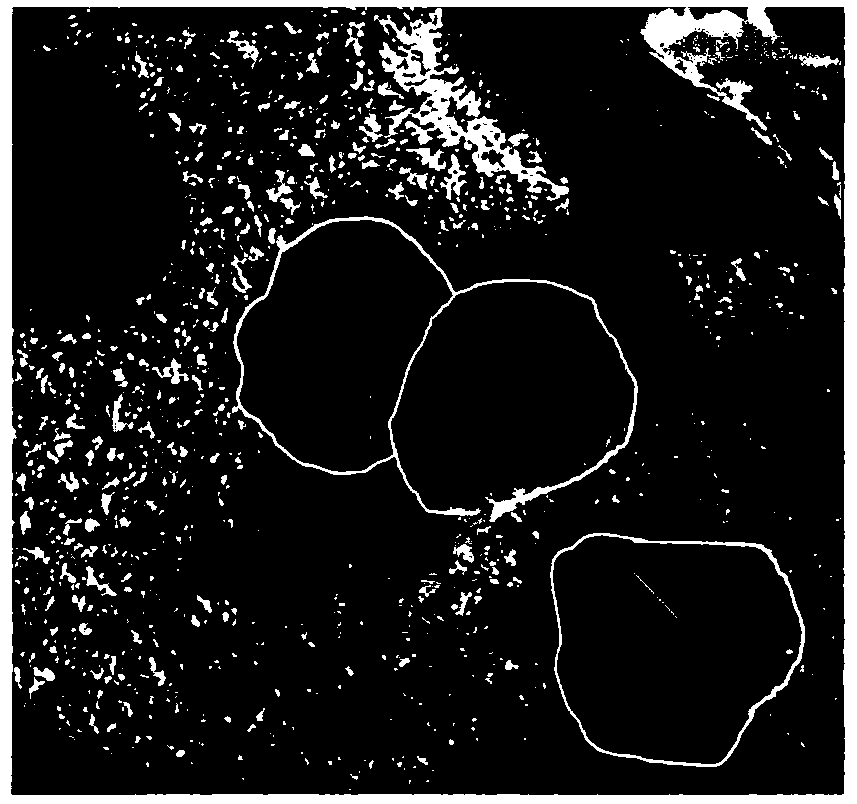

Image

Examples

Embodiment 1

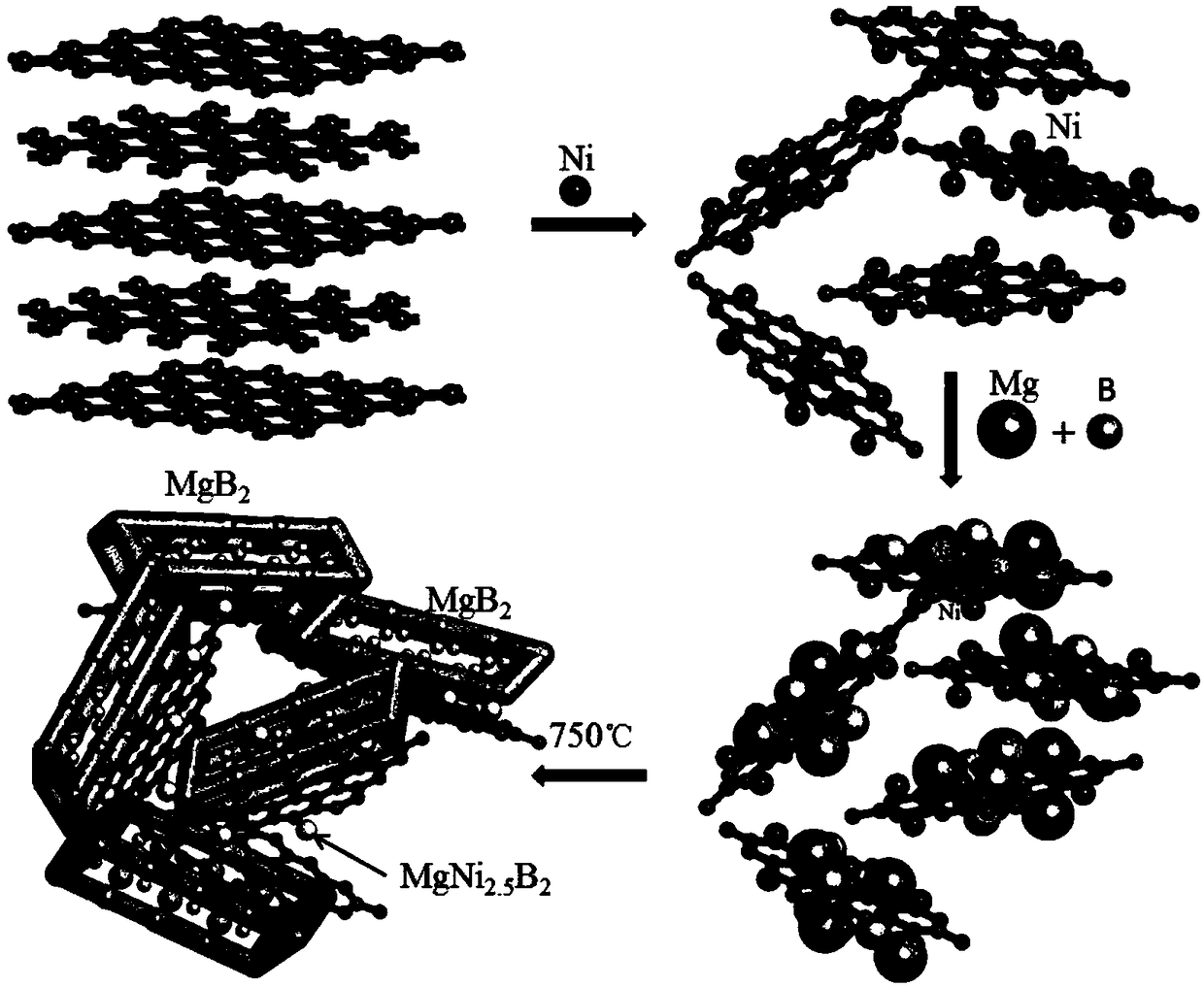

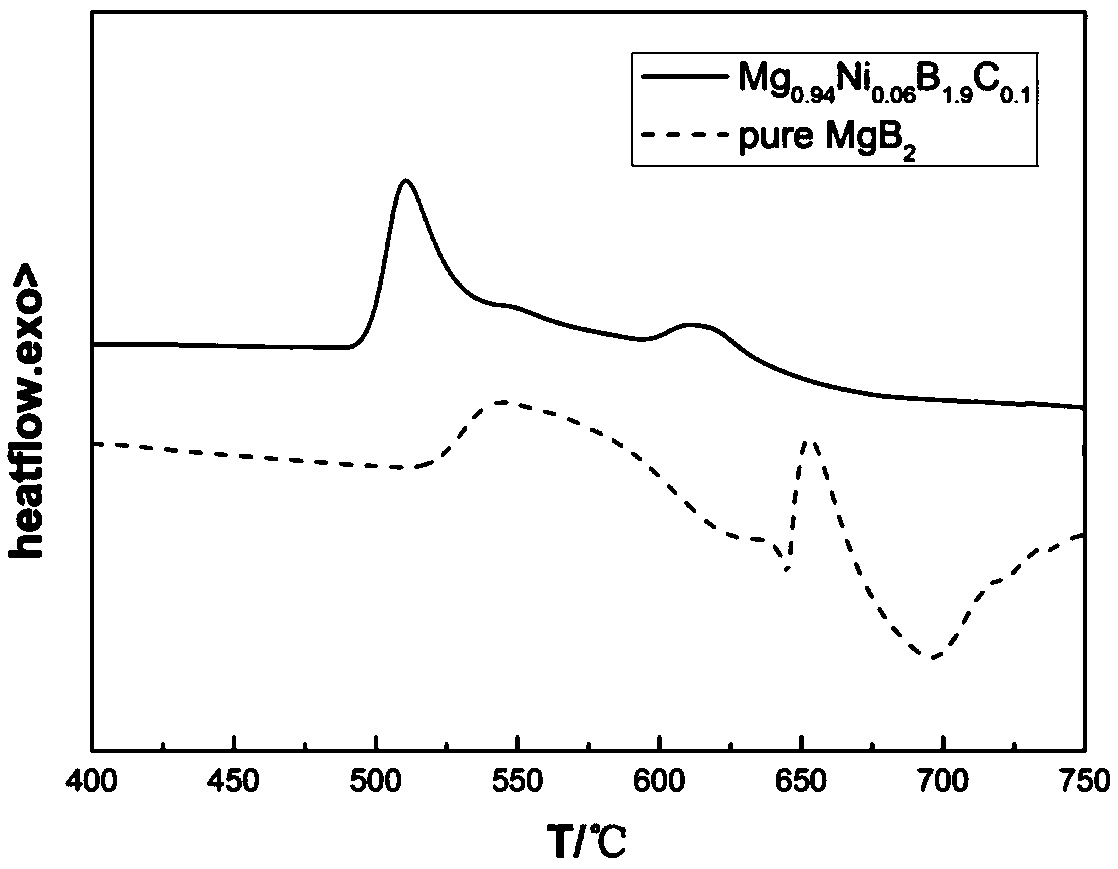

[0042] The method provided by the present invention utilizes metal powder and graphene co-doping to improve MgB 2 A method for grain-to-grain connectivity, the steps of which are:

[0043] 1) raw materials are commercially available magnesium powder (average diameter is 100 microns, purity 99.5%), amorphous boron powder (average diameter is 25 microns, purity 99%), graphene (single-layer graphene, purity 99%), metal Ni powder (average diameter 40 nm, purity 99.5%). The four are uniformly mixed at a molar ratio of Mg:B:C:Ni=0.94:1.9:0.1:0.06 to form a mixed raw material.

[0044] 2) Put 4g of the mixed raw material into the ball mill tank, the ratio of the balls to the mixed raw material is 30:1, the milling time is 8 hours, and the ball milling speed is 300rpm. During the ball milling process, in order to prevent the temperature in the tank from being too high, the milling is stopped every 55 minutes After 5 minutes, the Mg-B-C-Ni composite powder was obtained after ball mil...

Embodiment 2

[0050] The method provided by the present invention utilizes metal powder and graphene co-doping to improve MgB 2 A method for grain-to-grain connectivity, the steps of which are:

[0051] 1) raw materials are commercially available magnesium powder (average diameter is 100 microns, purity 99.5%), amorphous boron powder (average diameter is 25 microns, purity 99%), graphene (single-layer graphene, purity 99%), metal Cu powder (average diameter 100 nm, purity 99.5%). The four are uniformly mixed at a molar ratio of Mg:B:C:Cu=0.94:1.9:0.1:0.06 to form a mixed raw material.

[0052] 2) Put 4g of the mixed raw material into the ball mill tank, the ratio of the balls to the mixed raw material is 30:1, the milling time is 8 hours, and the ball milling speed is 300rpm. During the ball milling process, in order to prevent the temperature in the tank from being too high, the milling is stopped every 55 minutes After 5 minutes, the Mg-B-C-Cu composite powder was obtained after ball mi...

Embodiment 3

[0056] The method provided by the present invention utilizes metal powder and graphene co-doping to improve MgB 2 A method for grain-to-grain connectivity, the steps of which are:

[0057] 1) raw materials are commercially available magnesium powder (average diameter is 100 microns, purity 99.5%), amorphous boron powder (average diameter is 25 microns, purity 99%), graphene (single-layer graphene, purity 99%), metal Ag powder (average diameter 60 nm, purity 99.9%). The four are uniformly mixed at a molar ratio of Mg:B:C:Ag=0.92:1.8:0.2:0.08 to form a mixed raw material.

[0058] 2) Put 4g of the mixed raw material into the ball mill tank, the ratio of the balls to the mixed raw material is 35:1, the milling time is 8 hours, the milling speed is 300rpm, and the ball milling process is to prevent the temperature in the tank from being too high, and the milling is stopped every 55 minutes After 5 minutes, the Mg-B-C-Ag composite powder was obtained after ball milling,

[0059]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com