Methanation process for effectively recovering low-grade waste heat

A methanation, low-grade technology, applied in the field of methanation process, can solve the problems of ineffective recycling, low waste heat recovery rate of methanation unit, and small amount of by-product steam, etc. The effect of comprehensive energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

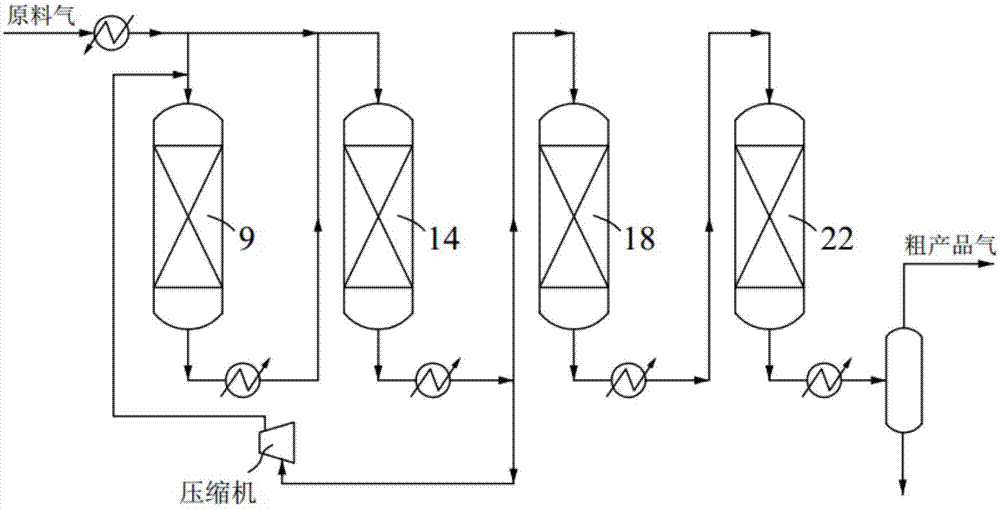

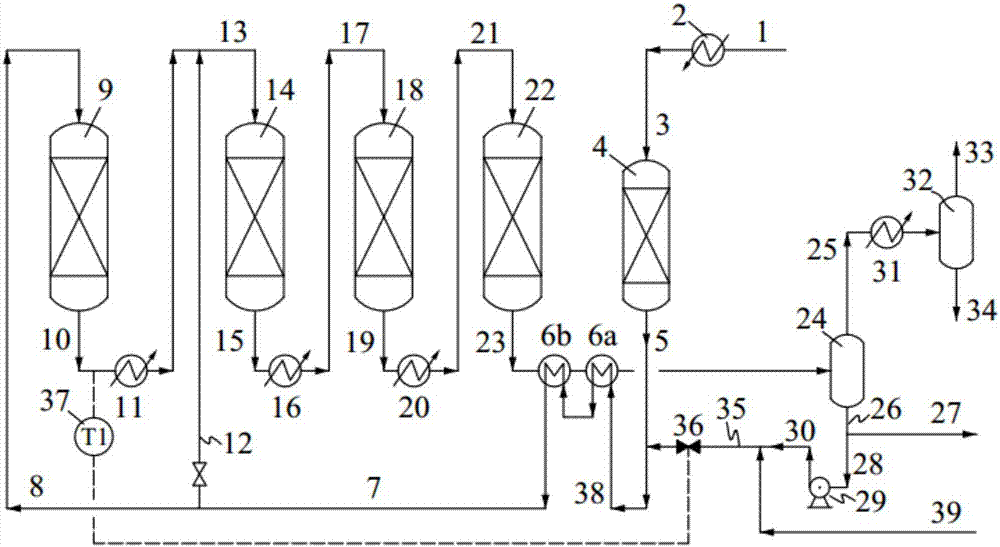

[0032] Taking the four-stage methanation reaction as an example, the annual production scale is 1 billion Nm 3 SNG, a new methanation process that effectively recovers low-grade waste heat is given. The process flow is as follows figure 2 As shown, the process includes the following steps:

[0033] The flow rate of raw synthesis gas 1 is 483470Nm 3 / h, temperature 30°C, pressure 3.3MPaG, composition (mol%): H 2 : 38.81, CO: 11.84, CO 2 : 35.26, H 2 O: 0.13, CH 4 : 13.78, N 2 : 0.11, Ar: 0.07, H 2 S: 0.1ppmv, after being preheated by the preheater 2, the preheated raw material gas 3 is obtained, and then enters the fine desulfurization reactor 4 to undergo a desulfurization chemical reaction to remove H 2 S and other sulfur-containing components to obtain desulfurized gas 5.

[0034]The obtained desulfurized gas 5 is mixed with the water in the water pipeline 35 to form the raw material gas 38 after water injection, enters the evaporator 6a for evaporation and gasifica...

Embodiment 2

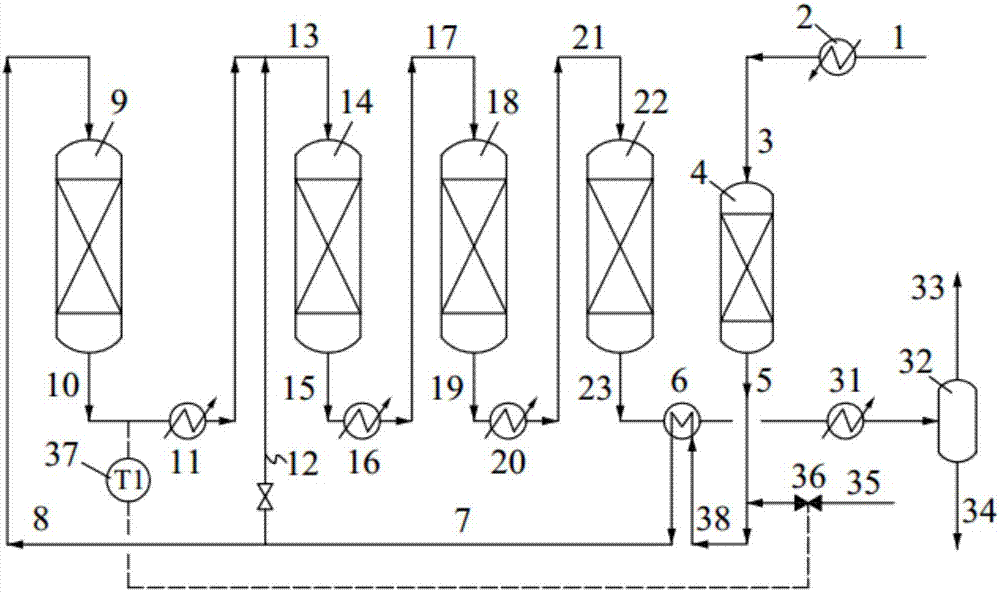

[0041] Taking the four-stage methanation reaction as an example, the annual production scale is 1 billion Nm 3 SNG, a new methanation process that effectively recovers low-grade waste heat is given. The process flow is as follows image 3 As shown, the process includes the following steps:

[0042] The flow rate of raw synthesis gas 1 is 767077Nm 3 / h, temperature 30°C, pressure 3.3MPaG, composition (mol%): H 2 : 47.21, CO: 15.03, CO 2 : 36.61, H 2 O: 0.13, CH 4 : 0.63, N 2 : 0.28, Ar: 0.11, H 2 S: 0.1ppmv, after being preheated by the preheater 2, it enters the fine desulfurization reactor 4 to undergo a desulfurization chemical reaction to remove H 2 S and other sulfur-containing components to obtain desulfurized gas 5.

[0043] The obtained desulfurized gas 5 is mixed with the water in the water pipeline 35 to form a water-injected raw material gas 38 , which enters the evaporation superheater 6 for evaporation, gasification and superheating to obtain a superheated ...

Embodiment 3

[0051] The flow rate, temperature, and composition of the raw material synthesis gas in this embodiment are the same as those in Example 1. The difference is that the pressure of the raw material synthesis gas in this embodiment is 6.0 MPaG. Taking the three-stage methanation reaction as an example, the operating temperature of the first separation tank 24 is The operating temperature of the fine desulfurization reactor 4 is 250°C, and the inlet temperature of the third-stage methanation reactor is 150°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com