Calcium carbonate for coatings and preparation method thereof

A technology of calcium carbonate and calcium carbonate stone, applied in the field of calcium carbonate for coatings and its preparation, can solve the problems of poor organic compatibility, easy aggregation, poor dispersion, etc., achieve low cost, expand application range, and simple preparation method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

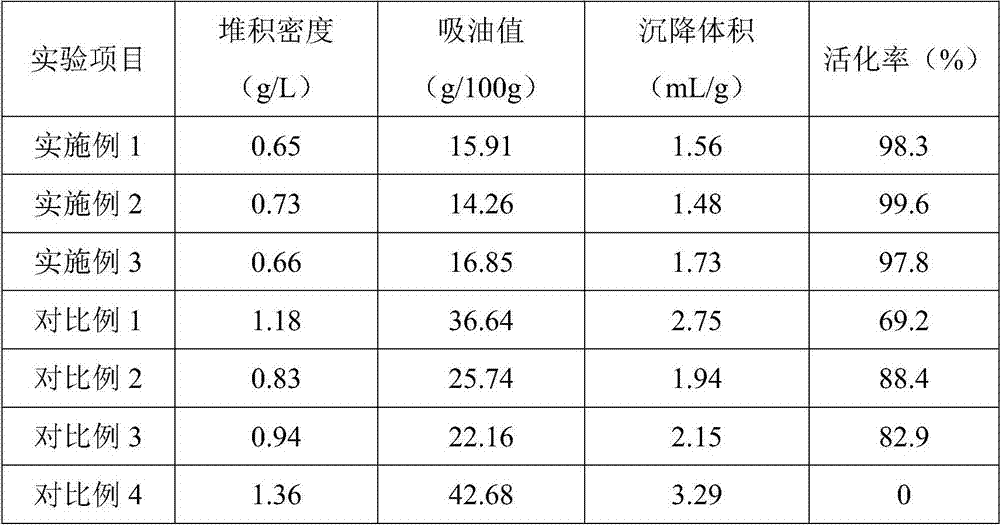

Examples

Embodiment 1

[0023] A kind of calcium carbonate that is used for coating, in weight part, comprises following raw material: 95 parts of calcium carbonate stone material, 3 parts of higher fatty alcohol, 2 parts of triisopropylamine, 10 parts of muscovite, sodium polystyrene sulfonate 6 parts, 0.9 parts of sodium methacrylate, 0.5 parts of N-aminoethyl-3-aminopropylmethyldimethoxysilane, 0.3 parts of trimethylbutyl peroxysilane, sodium polynaphthaldehyde sulfonate 0.6 part of salt, 0.8 part of allyl methacrylate, 0.2 part of sodium lignosulfonate, 2-(4,6-bis(2,4-dimethylphenyl)-1,3,5-triazine 0.1 part of -2-yl)-5-methoxyphenol, 0.4 part of magnesium oxide, 0.1 part of polyisocyanate, 0.5 part of nano-titanium dioxide, and 0.3 part of epoxidized soybean oil.

[0024] A kind of calcium carbonate preparation method for coating, coating method comprises the following steps:

[0025] S1: Calcium carbonate stone is cleaned to remove impurities, then dried to remove surface moisture, after crushi...

Embodiment 2

[0037] A kind of calcium carbonate that is used for coating, in weight part, comprises following raw material: 113 parts of calcium carbonate stones, 15 parts of muscovite, 13 parts of sodium polystyrene sulfonate, 1.5 parts of sodium methacrylate, N- 1.2 parts of aminoethyl-3-aminopropylmethyldimethoxysilane, 0.8 parts of trimethylbutyl peroxysilane, 0.9 parts of polynaphthaldehyde sulfonic acid sodium salt, 1.5 parts of allyl methacrylate, 0.5 parts of sodium lignosulfonate, 0.3 parts of 2-(4,6-bis(2,4-dimethylphenyl)-1,3,5-triazin-2-yl)-5-methoxyphenol , 0.6 parts of magnesium oxide, 0.3 parts of polyisocyanate, 1.1 parts of nano-titanium dioxide, and 0.8 parts of epoxy soybean oil.

[0038] A kind of calcium carbonate preparation method for coating, coating method comprises the following steps:

[0039] S1: Calcium carbonate stone is cleaned to remove impurities, then dried to remove surface moisture, after crushing, add higher fatty alcohol and triisopropylamine to grind...

Embodiment 3

[0051] A kind of calcium carbonate that is used for coating, in weight part, comprises following raw material: 124 parts of calcium carbonate stone material, 5 parts of higher fatty alcohol, 5 parts of triisopropylamine, 16 parts of muscovite, sodium polystyrene sulfonate 9 parts, 1.1 parts of sodium methacrylate, 0.9 parts of N-aminoethyl-3-aminopropylmethyldimethoxysilane, 0.5 parts of trimethylbutylperoxysilane, sodium polynaphthaldehyde sulfonate 0.7 parts of salt, 1.2 parts of allyl methacrylate, 0.3 parts of sodium lignosulfonate, 2-(4,6-bis(2,4-dimethylphenyl)-1,3,5-triazine 0.2 parts of -2-yl)-5-methoxyphenol, 0.8 parts of magnesium oxide, 0.2 parts of polyisocyanate, 1.2 parts of nano-titanium dioxide, and 1.6 parts of epoxidized soybean oil.

[0052] A kind of calcium carbonate preparation method for coating, coating method comprises the following steps:

[0053] S1: Calcium carbonate stone is cleaned to remove impurities, then dried to remove surface moisture, afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com