Landfill leachate treatment system and treatment method

A technology for landfill leachate and treatment system, applied in landfill leachate treatment system and treatment field, can solve the problems of deteriorating operating conditions, poor biodegradability, poor operating environment, etc., to reduce the number of equipment, improve oxygen utilization, reduce supporting The effect of the facility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

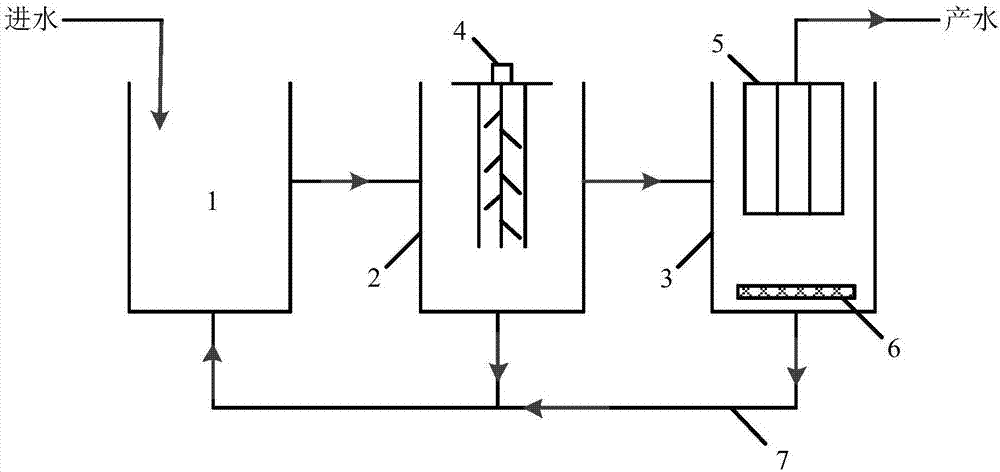

[0035] The invention provides a landfill leachate treatment system, such as figure 1 As shown, it includes anoxic pool 1, aerobic pool 2 and membrane pool 3 arranged in sequence; wherein, the aerobic pool 2 is provided with a pure oxygen aeration device 4, and the membrane pool 3 is provided with a curtain type ultra- filter membrane 5 , blowing aeration device 6 , and the bottom of the membrane pool 3 is also provided with a return pipe 7 communicating with the anoxic pool 1 .

[0036] In the landfill leachate treatment system provided by the present invention, it also includes an anaerobic pond arranged at the front end of the anoxic pond 1 , and a pretreatment unit arranged at the front end of the anoxic pond 1 .

[0037] The pretreatment unit is used for pretreatment of landfill leachate. Since the landfill leachate has the characteristics of high organic matter content, high heavy metal ion content, high ammonia nitrogen content, high salinity and poor biodegradability, ...

Embodiment 2

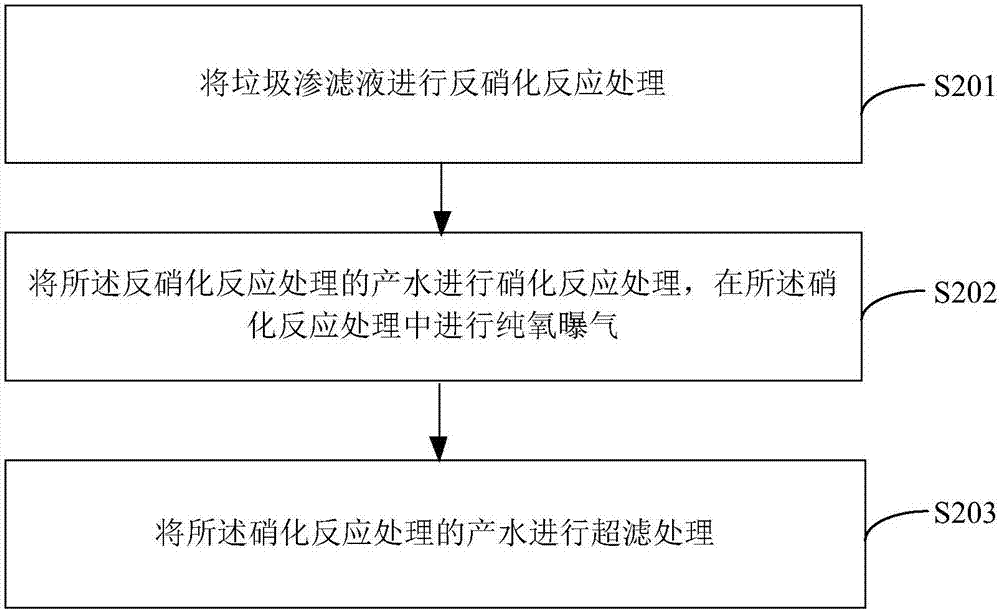

[0046] The invention provides a method for treating landfill leachate, such as figure 2 As shown, the main steps of the processing method include:

[0047] Step S201: performing denitrification reaction on the landfill leachate;

[0048] Step S202: performing nitrification treatment on the denitrification-treated product water, and performing pure oxygen aeration during the nitrification treatment;

[0049] Step S203: Ultrafiltration treatment is performed on the product water treated by the nitrification reaction.

[0050] The landfill leachate treatment method provided by the invention includes a pretreatment step.

[0051] Exemplarily, the pretreatment step adopts coagulation and precipitation, specifically, adding coagulant and coagulant aid in the coagulation tank, which can be fully mixed with the leachate and precipitated to remove heavy metal ions and alkaline earth metals in the leachate (calcium, magnesium), some non-heavy metals (arsenic, fluorine, sulfur, boron...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com