Surface surfacing welding process of crystallizer foot roll and workpiece clamping tool

A technology of surface surfacing and workpiece clamping, applied in welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of low fatigue resistance, large bending deformation of workpiece, long axial dimension, etc., to improve the surface hardness of workpiece and The effect of fatigue resistance and good overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

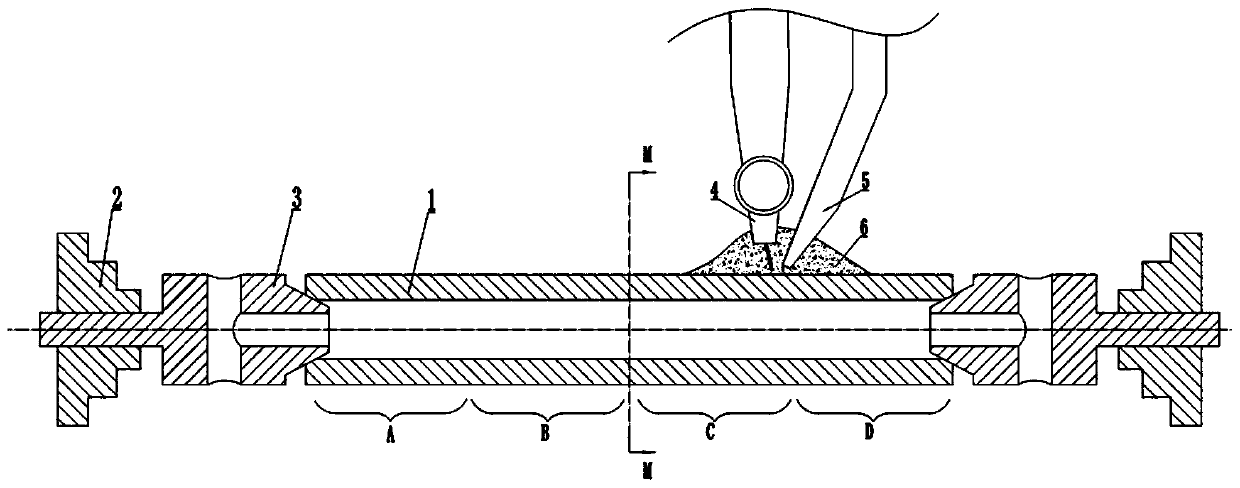

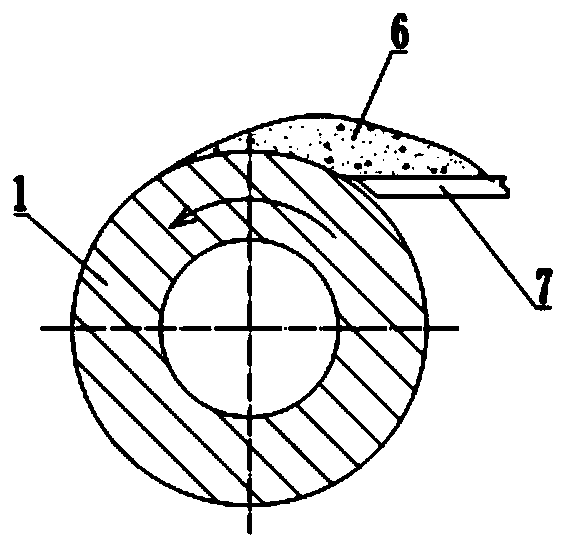

[0035] see figure 1 , figure 2 , image 3 , the crystallizer foot roll surface surfacing process described in the present invention adopts the submerged arc automatic welding method to implement surfacing operation on the surface of the workpiece 1, the preferred welding current is 250-350A, the welding voltage is 25-32V, and the welding method is single pass For spiral welding, the weld bead overlap is 1 / 2, and the specific operation is as follows:

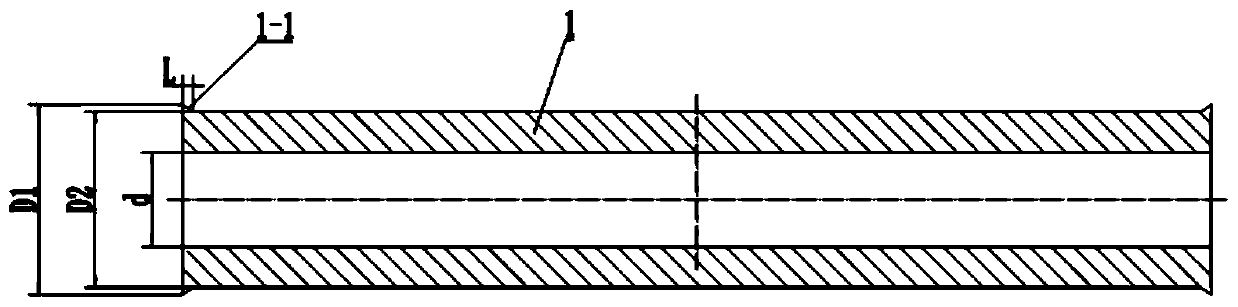

[0036] a. Pre-welding processing: select the round steel raw material of 42CrMo and diameter D1=100mm, and carry out turning processing to obtain a casing workpiece with an outer diameter of D2=92mm and an inner diameter of d=45mm, and leave a length at both ends of the workpiece 1 Guide groove 1-1 with dimension L=6mm;

[0037] b. Workpiece clamping: clamp both ends of the workpiece 1 on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com