Prestressed Concrete Cantilever Support Structure with Controllable Deformation and Its Design and Construction Method

A technology of supporting structure and design method, which is applied in the direction of basic structure engineering, excavation, construction, etc., to achieve the effect of improving the bending and shear bearing capacity, solving the problem of excessive size and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

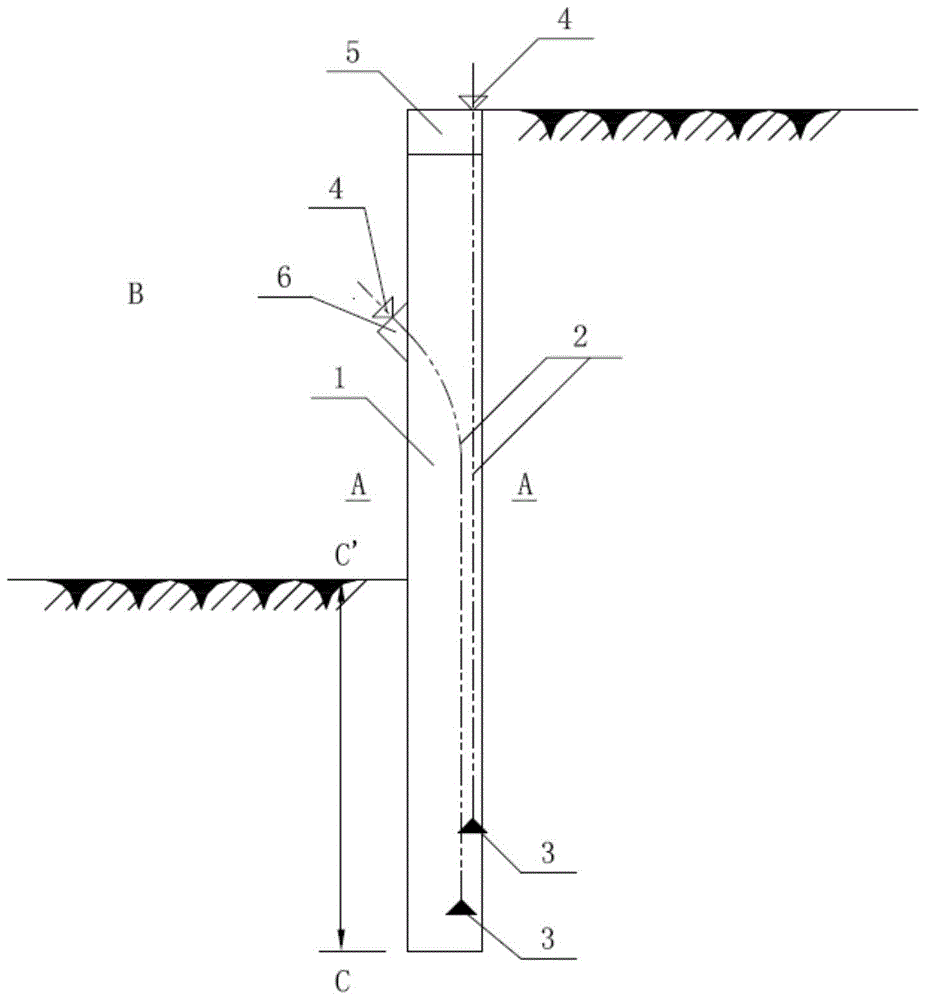

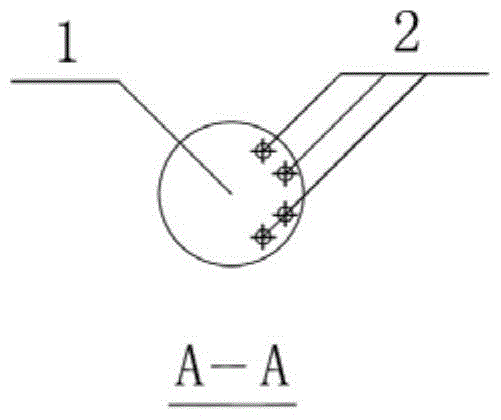

[0038] refer to figure 1 , the controllable deformation of the prestressed concrete cantilever support structure described in this embodiment includes: an ordinary concrete cantilever support structure, prestressed tendons, fixed ends, and tension ends; the ordinary concrete cantilever support structure includes: concrete and The reinforcement cage configured in the concrete; the tension end and the fixed end are respectively located at the upper and lower ends of the prestressed tendon; the prestressed tendon and the fixed end anchoring the prestressed tendon are arranged In the ordinary concrete cantilever support structure, and synchronous construction with the ordinary concrete cantilever support structure; the tension end is anchored on the crown beam at the top of the ordinary concrete cantilever support structure and / or anchored on the On the corbels of the side walls of the ordinary concrete cantilever support structure. The number of bundles of the prestressed tendon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com