Ceramic composite beads and methods for making the same

A technology for ceramics and glass ceramics, which can be used in separation methods, manufacturing tools, glass manufacturing equipment, etc., and can solve problems such as producing glass ceramics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

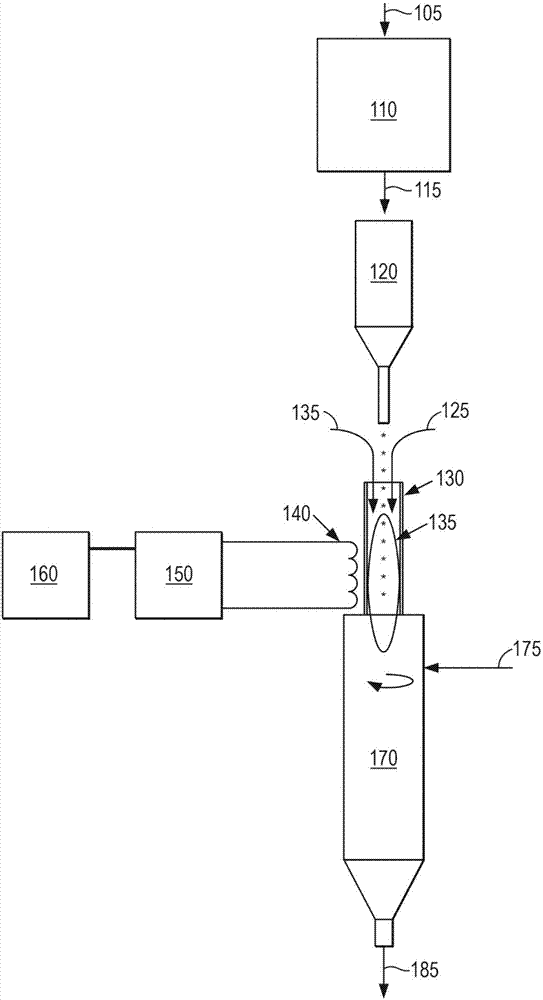

Method used

Image

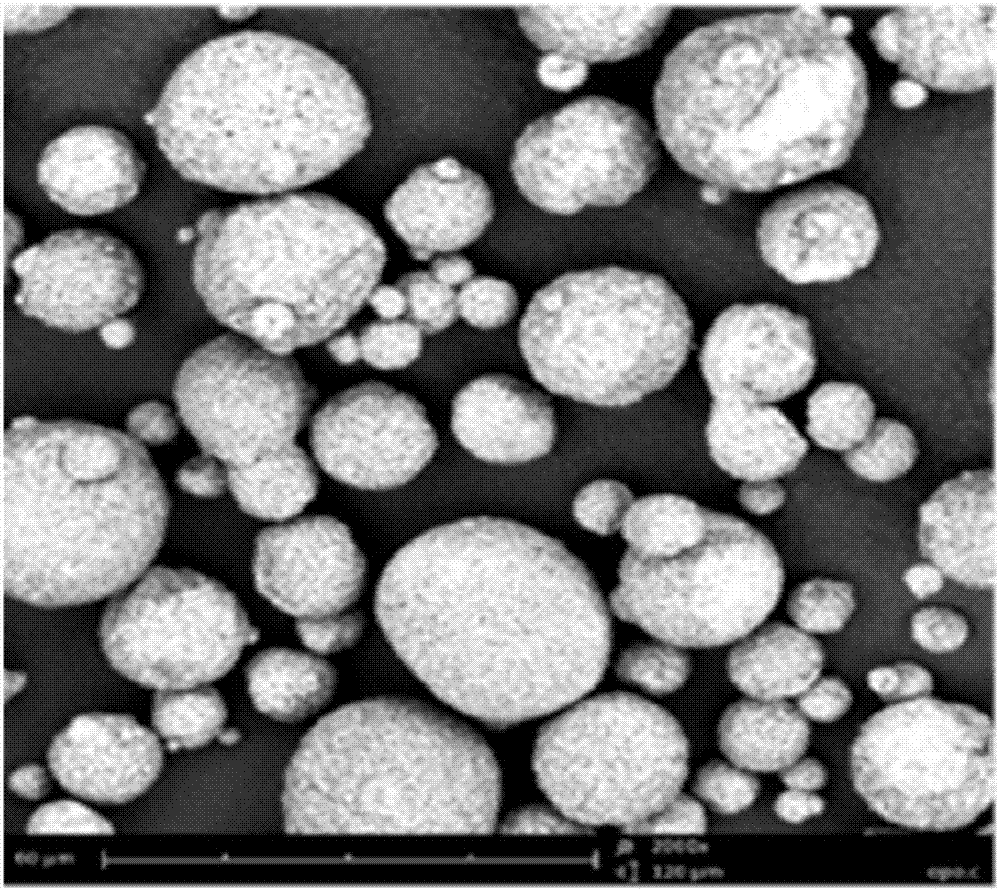

Examples

example

[0115] Batch

[0116] The following compositions A and B were prepared by combining the components listed in the table below to form a slurry:

[0117] Composition A

[0118]

Function

amount (weight)

Dry IngredientsX

Calcined Alumina A1000 SGD

40.18

Titanium dioxide R101

50.86

Oxide

7.96

Ground Cerium Oxide

Oxide

1.00

Total X = 100

Liquid additive Y

Colloidal Silica Ludox AS-40

Oxide

48.40

Deionized water

87.50

Duramax D-3005

Dispersant

0.55

Duramax B-1022

5.00

Total X+Y=241.45

[0119] Composition B

[0120]

Function

amount (weight)

Dry IngredientsX

Calcined Alumina A1000 SGD

Oxide

43.04

Titanium dioxide R101

Oxide

51.90

Magnesium Oxide Magchem 10

Oxide

5....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com