Lithium flow battery system driven by virtue of motor

A motor-driven, flow battery technology, used in fuel cells, fuel cell additives, electrolyte flow treatment, etc., can solve problems such as reduced service life of liquid pumps, contact, electrode suspension leakage, etc., and achieve the effect of preventing overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0110] The present invention will be further described through embodiments below in conjunction with the accompanying drawings.

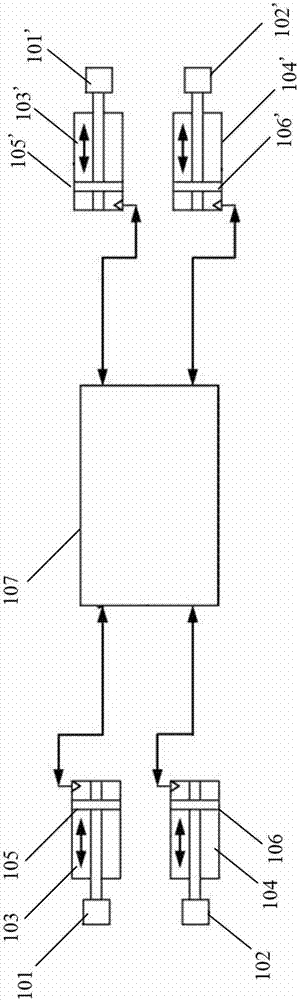

[0111] figure 1 is a schematic diagram of a lithium flow battery system according to the prior art. The system includes first and second positive motors 101 and 102, first and second negative motors 101' and 102', first and second positive cylinders 103 and 104, first and second negative cylinders 103', 104', first and second positive pistons 105, 106, first and second negative pistons 105', 106', reactor 107 and liquid pipeline. Wherein, the piston rod of the piston is pushed by the motor, so that the piston moves in the hydraulic cylinder. Through the movement of the piston, the electrode suspension in the liquid cylinder enters the reaction chamber of the reactor through the liquid pipeline, and the electrode suspension in the reaction chamber enters another liquid cylinder through the liquid pipeline, thereby completing the reaction Fluid cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com