A kind of solar energy selective absorbing coating of multilayer structure and preparation method thereof

A technology of multi-layer structure and absorption coating, applied in the field of solar coating materials, can solve the problems of optical performance degradation, damage to the original structure of multi-layer coatings, easy occurrence of cracks, etc., and achieves reduction of infrared emissivity and porosity. , the effect of enhancing the absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

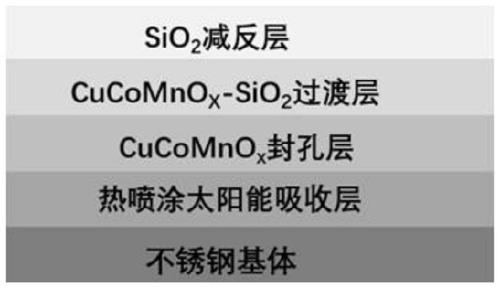

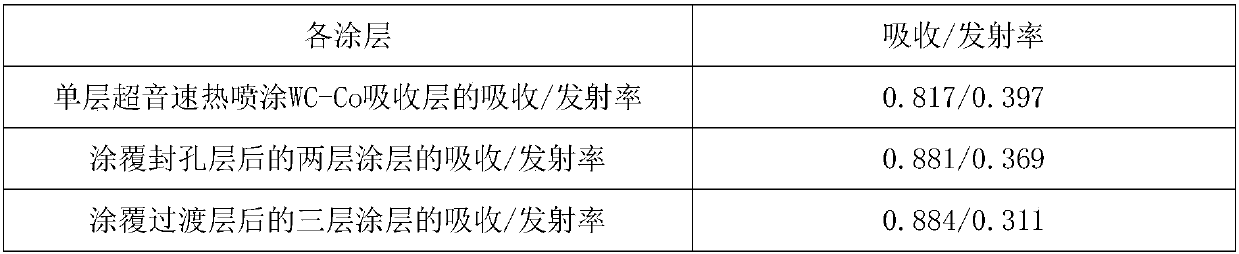

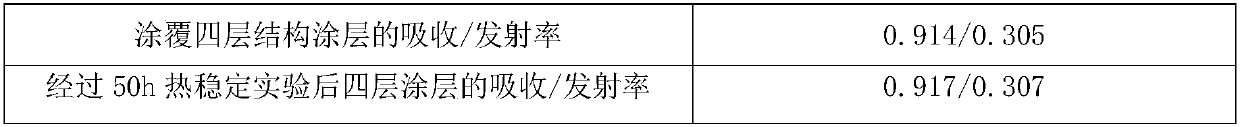

[0032] A multi-layer solar selective absorbing coating, including WC-Co supersonic thermal spraying solar absorbing layer from the bottom layer to the surface, the first layer of CuCoMnO x Sealing layer, second layer CuCoMnO x -SiO 2 transition layer and third layer of SiO 2 AR layer composition.

[0033] The preparation process of the solar selective absorbing coating of the above-mentioned multilayer structure comprises the following steps:

[0034] (1) Polish the WC-Co solar selective absorbing coating obtained by supersonic thermal spraying with water-abrasive sandpaper, and then use 1000 mesh, 1500 mesh, and 2000 mesh sandpaper to cross-polish the coating, and each time the polishing process faces Use even force in one sanding direction. Use a roughness measuring instrument to test its surface roughness until its roughness is reduced to R A = about 1.3 μm, after polishing, use ethanol solution to ultrasonically clean the coating for 30 minutes.

[0035] (2) Preparat...

Embodiment 2

[0050] A multi-layer solar selective absorbing coating, including WC-Co supersonic thermal spraying solar absorbing layer from the bottom layer to the surface, the first layer of CuCoMnO x Sealing layer, second layer CuCoMnO x -SiO 2 transition layer and third layer of SiO 2 AR layer composition.

[0051] The preparation process of the solar selective absorbing coating of the above-mentioned multilayer structure comprises the following steps:

[0052] (1) Polish the WC-Co solar selective absorbing coating obtained by supersonic thermal spraying with water-abrasive sandpaper, and then use 1000 mesh, 1500 mesh, and 2000 mesh sandpaper to cross-polish the coating, and each time the polishing process faces Use even force in one sanding direction. Use a roughness measuring instrument to test its surface roughness until its roughness is reduced to R A =1.7μm or so, use ethanol solution to ultrasonically clean the coating for 30 minutes after polishing.

[0053] (2) Preparation...

Embodiment 3

[0068] A multi-layer solar selective absorbing coating, from the bottom to the surface, including Ni-Mo supersonic thermal spraying solar absorbing layer, the first layer of CuCoMnO x Sealing layer, second layer CuCoMnO x -SiO 2 transition layer and third layer of SiO 2 AR layer composition.

[0069] The preparation process of the solar selective absorbing coating of the above-mentioned multilayer structure comprises the following steps:

[0070] (1) Polish the Ni-Mo solar selective absorbing coating obtained by supersonic thermal spraying with water-abrasive sandpaper, and then use 1000 mesh, 1500 mesh, and 2000 mesh sandpaper to cross-polish the coating, and each time the polishing process faces Use even force in one sanding direction. Use a roughness measuring instrument to test its surface roughness until its roughness is reduced to R A = about 1.5 μm, after polishing, use ethanol solution to ultrasonically clean the coating for 30 minutes.

[0071] (2) Preparation o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com