A method for pretreating high-titanium vanadium-titanium magnetite to prepare pellets

A kind of technology of vanadium titanomagnetite and high titanium type

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

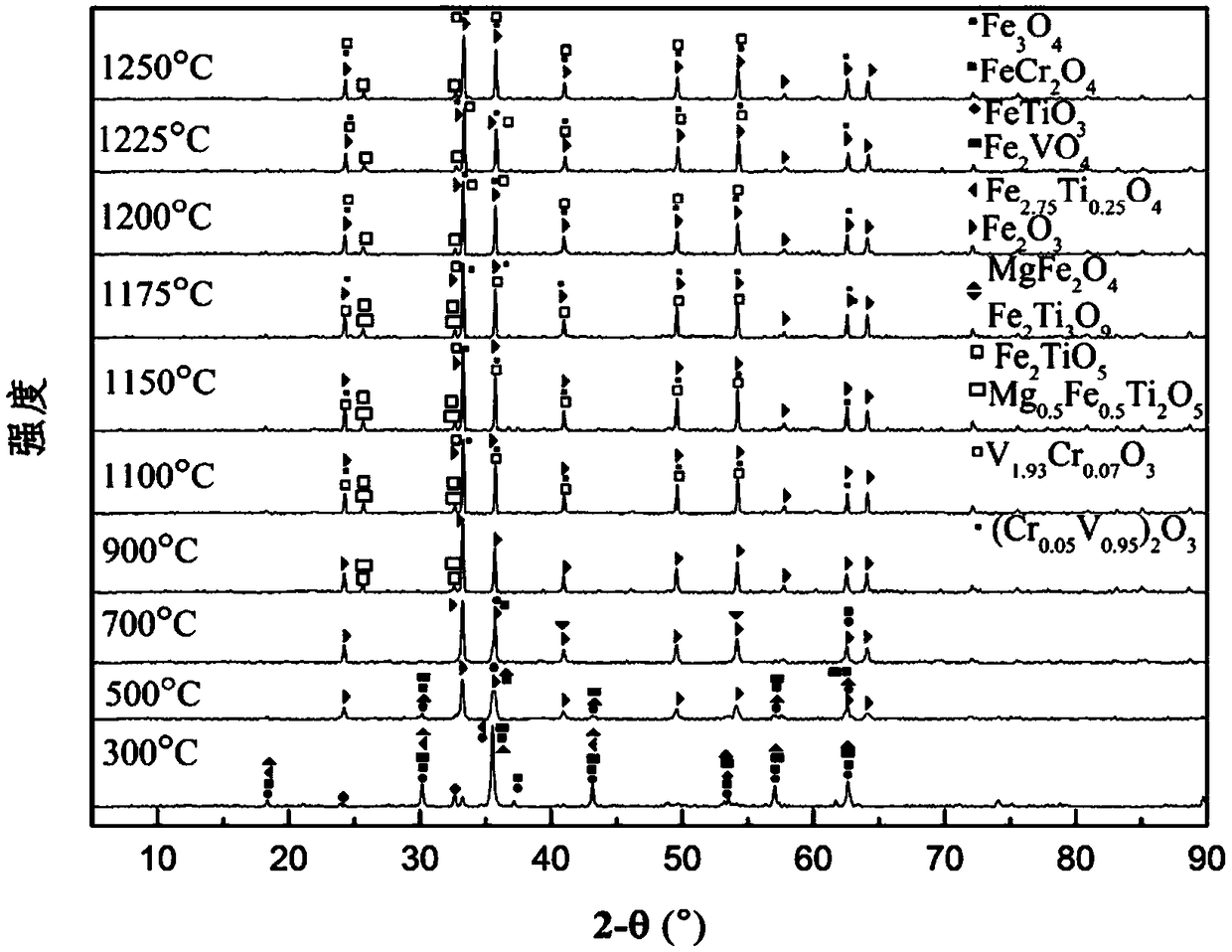

Image

Examples

Embodiment 1

[0045] A method for preparing pretreated high-titanium type vanadium-titanium magnetite pellets, the method comprising:

[0046] 1. Pretreatment

[0047] Take high-titanium vanadium-titanium magnetite and finely grind high-titanium vanadium-titanium magnetite in conical ball mill, horizontal ball mill or dry slag ball mill and other grinding equipment to obtain high-titanium vanadium-titanium magnet Mineral powder. Among them, the parameters of the conical ball mill are: the grinding capacity is 4kg, the rotating speed is 90r / min, the grinding concentration is 65% to 75%, the ball loading capacity is 10kg, and the ball milling time is 1 to 60min; the parameters of the horizontal ball mill are: The ore quantity is 2-5kg, the speed is 35-55r / min, the ball milling time is 1-60min, and the ball loading capacity is 25kg; the parameters of the dry-type mineral powder ball mill are: the grinding quantity is 2-5kg, the speed is 30-45r / min, The ball milling time is 1-60min, and the b...

Embodiment 2

[0072] A method for pretreating high-titanium vanadium-titanium magnetite to prepare pellets, the present embodiment is based on embodiment 1, and the specific operation steps are as follows:

[0073] 1. Pretreatment

[0074] Take 4kg of high-titanium vanadium-titanium magnetite in a conical ball mill with a rotating speed of 90r / min, a grinding concentration of 70%, a ball loading capacity of 10kg, and a ball milling time of 30min.

[0075] After grinding, the particle size distribution of the high-titanium vanadium-titanium magnetite was measured by wet sieving, and 92% of the particles had a particle size smaller than 75 μm.

[0076] 2. Raw material drying

[0077] The pretreated high-titanium vanadium-titanium magnetite was dried in a draft drying oven at a temperature of 108°C for 2 hours, and the moisture content of the dried high-titanium vanadium-titanium magnetite was measured to be 1.13%.

[0078] 3. Mixing stage

[0079] Add 0.6% of its weight of calcium-based be...

Embodiment 3

[0094] This embodiment is on the basis of embodiment 1, concrete operation is as follows:

[0095] 1. Pretreatment

[0096] Take 5 kg of high-titanium vanadium-titanium magnetite in a horizontal ball mill with a rotating speed of 40 r / min, a ball loading capacity of 25 kg, and a ball milling time of 25 min.

[0097] After grinding, the particle size distribution of the high-titanium vanadium-titanium magnetite was measured by wet sieving, and 86% of the particles had a particle size smaller than 75 μm.

[0098] 2. Raw material drying

[0099] The pre-grinded high-titanium vanadium-titanium magnetite and 0.7% by weight of hydrogen-based bentonite were dried in a draft drying oven at 105°C for 2.1 hours, and the water content of the iron ore was measured to be 1.15%.

[0100] 3. Mixing stage

[0101] Add hydrogen-based bentonite to high-titanium vanadium-titanium magnetite powder for 18 minutes of dry mixing. After the dry mixing is completed, use a high-pressure sprayer to e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com