Nylon material for noise reduction pad of automobile and preparation method of nylon material

A technology for noise reduction sheets and automobiles, which is applied in the field of auto parts and can solve problems such as poor aging resistance, difficult molding process, and low tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

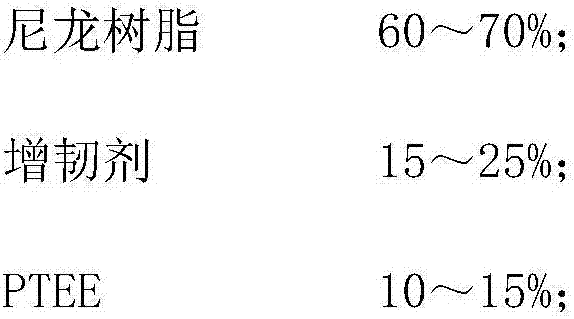

Method used

Image

Examples

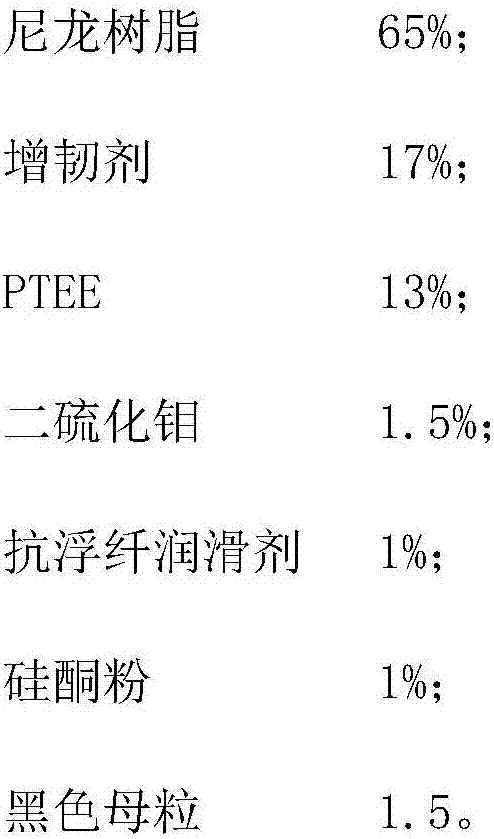

Embodiment 1

[0022] Step 1: Measure 60g of PA6, 24g of toughening agent, 12g of PTEE, 1g of molybdenum disulfide, 0.5g of anti-floating fiber lubricant, 1g of silicone powder and 1.5g of black masterbatch, add high-speed mixing Mix in the middle for 8-10 minutes, and control the temperature to gradually increase to 70°C during this process, and cool to room temperature after shutting down;

[0023] Step 2: Extrude and granulate the mixture obtained in step 1 through a twin-screw extrusion granulator to prepare modified functional pellets. The temperature of the extruder host is controlled at 110-190°C, and the temperature from the feeding port to the first zone of the die is 110-120℃, the temperature in the second zone is 110-130℃, the temperature in the third zone is 115-140℃, the temperature in the fourth zone is 130-150℃, the temperature in the fifth zone is 150-185℃, the temperature in the sixth zone is 160-180℃, the temperature in the seventh zone is 170- 190°C, die head temperature 1...

Embodiment 2 3

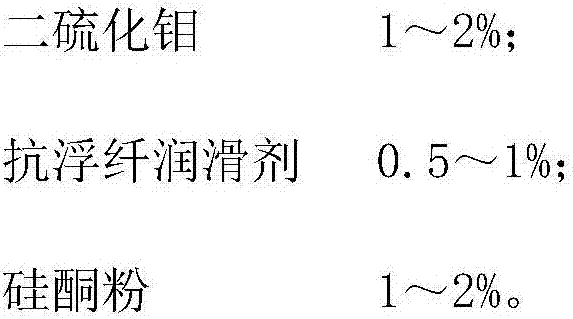

[0025] Embodiment two and three: according to the flow process of embodiment one, change the weight ratio of each component of nylon resin, toughening agent, PTEE, molybdenum disulfide, anti-floating fiber lubricant, silicone powder and black masterbatch respectively, as Shown in table 1: table 1: the weight percent of each component of embodiment two and three

[0026]

[0027] In the above embodiments 1 to 3, the nylon resin is PA6, and the anti-floating fiber lubricant is TAF. The toughening agent in embodiment one is maleic anhydride grafted POE, the toughening agent in embodiment two is maleic anhydride grafted EPDM, the toughening agent in embodiment three is maleic anhydride grafted EPDM and maleic anhydride grafted A mixture of acid anhydride grafted POE with a ratio of 1:1.

[0028] The noise reduction sheets obtained in the above-mentioned Examples 1 to 3 and the existing noise reduction sheets on the market were respectively made into international tensile splin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com