Preparation method of high-dietary-fiber-content kiwi fruit superfine powder with bowel relaxing function and chewable tablets prepared from powder

A technology of superfine powder and kiwifruit, applied in the food field, can solve the problems of insufficient utilization of kiwifruit, large particle size span, poor uniformity, etc., and achieve the effects of preventing or improving slow transit constipation, easy absorption and increasing utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

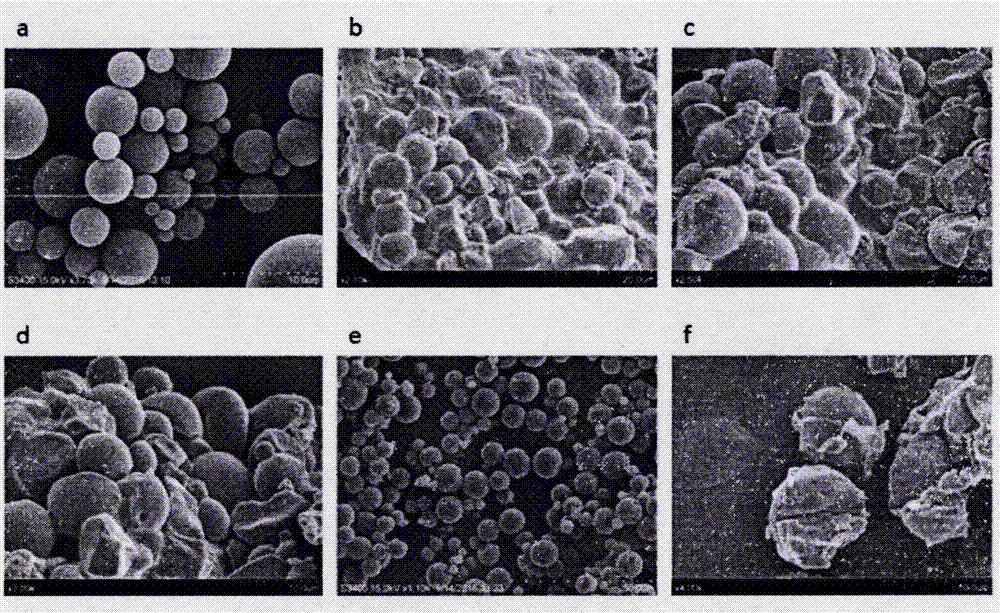

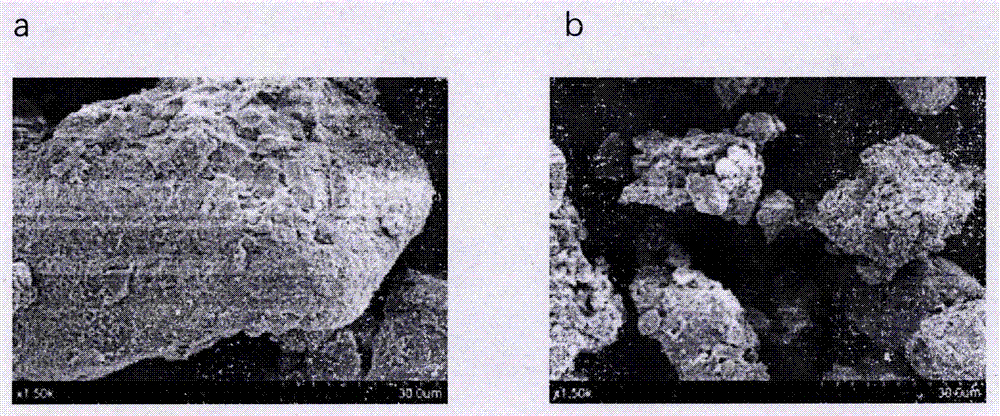

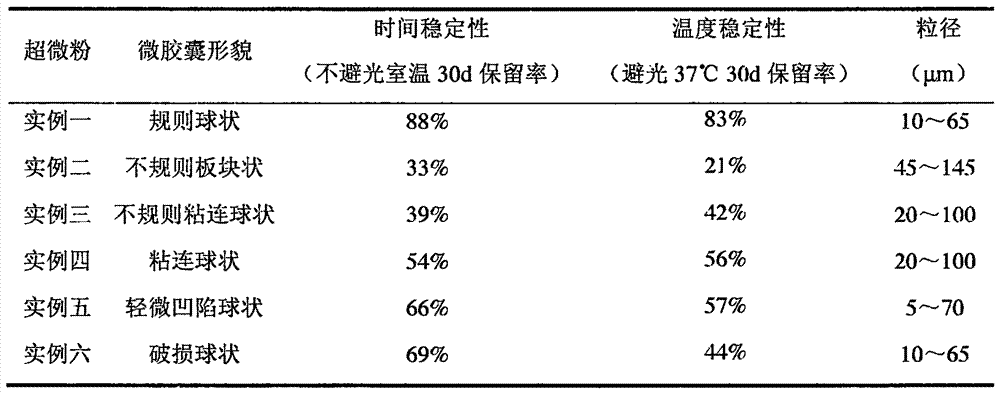

Embodiment 1

[0030] 1 Preparation of high-food kiwi superfine powder

[0031] (1) Pretreatment: take fresh kiwifruit, wash with distilled water, peel and cut into pieces, add 0.5 times of distilled water according to the weight of kiwifruit pieces, and then add 0.2% sodium bisulfite to protect the color. After squeezing the juice, filter it with a 40-mesh sieve to separate and obtain kiwi fruit pulp and kiwi fruit pomace.

[0032] (2) High-pressure homogenization: Homogenize the coarse pulp under the condition of 20-40MP to obtain fine pulp with uniform texture.

[0033] (3) Supramolecular microencapsulation: add γ-cyclodextrin to the fine fruit pulp in an amount of 17% of the weight of the fine fruit pulp, and grind twice to obtain a grinding liquid.

[0034] (4) Emulsifying and homogenizing: adding an emulsifier caprylic acid glycerin to the grinding liquid in an amount of 1.5% of the weight of the grinding liquid, and homogenizing for 3 times to obtain a homogeneous liquid.

[0035] (...

Embodiment 2

[0042] Steps (1), (2), (5), (6), (8) and (10) are the same as in Embodiment 1.

[0043] (3) Supramolecular microencapsulation: α-cyclodextrin was added to the fine pulp in an amount of 12% of the weight of the fine pulp, and ground once to obtain a grinding liquid.

[0044] (4) Emulsification and homogenization: add emulsifier glyceryl caprylate to the grinding liquid in an amount of 0.5% of the weight of the grinding liquid, and homogenize once to obtain a homogeneous liquid.

[0045] (7) Ultrafine pulverization: the volume ratio of microencapsulated dry powder and agate balls (3 mm in diameter) is 1:1, placed in an agate grinding bowl at a speed of 260 r / min, and ground for 20 minutes to obtain microencapsulated fruit ultrafine powder once.

[0046] (9) Dry-process modified dietary fiber: the volume ratio of microencapsulated dry powder and agate balls (3mm in diameter) is 1:1, placed in an agate grinding bowl, the speed is 260r / min, the grinding time is 30min, and the grind...

Embodiment 3

[0048] Steps (1), (2), (5), (6), (8), (9) and (10) are the same as in Embodiment 1.

[0049] (3) Supramolecular microencapsulation: β-cyclodextrin was added to the fine fruit pulp in an amount of 15% of the weight of the fine fruit pulp, and ground twice to obtain a grinding liquid.

[0050] (4) Emulsification and homogenization: add emulsifier caprylic acid glycerin to the grinding liquid, the addition amount is 1% of the weight of the grinding liquid, and homogenize twice to obtain a homogeneous liquid.

[0051] (7) Superfine pulverization: the volume ratio of microencapsulated dry powder and agate balls (3 mm in diameter) is 1:1, placed in an agate grinding bowl at a speed of 280 r / min, and ground for 25 minutes to obtain microencapsulated fruit superfine powder twice.

[0052] (9) Dry method modified dietary fiber: the volume ratio of microencapsulated dry powder and agate balls (diameter 3mm) is 1:1, placed in an agate grinding bowl, the rotating speed is 280r / min, the gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com