Temperature compensation equalization circuit of TR assembly

A technology of equalizing circuit and equalizing resistance, which is applied in the direction of voltage/temperature change compensation, electrical components, amplification control, etc. It can solve problems such as poor temperature compensation effect in high frequency bands, high and low temperature gain fluctuations, and inability to dynamically adjust, etc., to achieve gain balance Adjustable volume, adjustable temperature compensation range, and improved productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

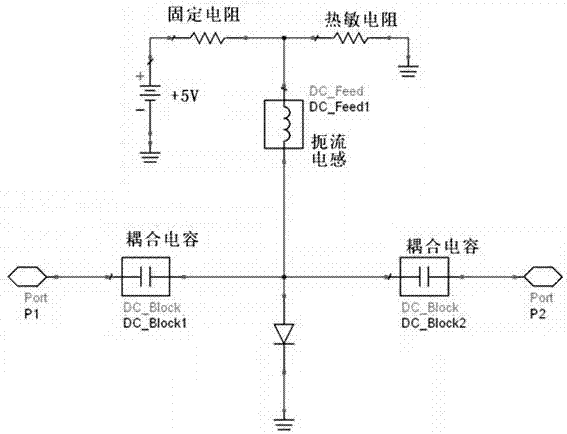

[0029] A temperature compensation equalization circuit of a TR component, comprising a temperature compensation circuit and an equalization circuit; the temperature compensation circuit adopts a PIN die and a DC bias circuit to realize the temperature compensation function; the DC bias circuit is composed of a fixed resistance and a thermistor connected in series; the fixed resistor and the thermistor are sequentially connected to a choke inductance and a diode, and then grounded; the choke inductance is connected to the anode of the diode; the anode of the diode is respectively connected to a temperature compensation through a coupling capacitor input and output terminals of the circuit.

[0030] The temperature compensation circuit among the present invention is as figure 1 As shown, the PIN die + peripheral DC bias circuit is used to realize the temperature compensation function. When the temperature is high, the resistance of the thermistor is almost 0 ohms, so that the PI...

specific Embodiment 2

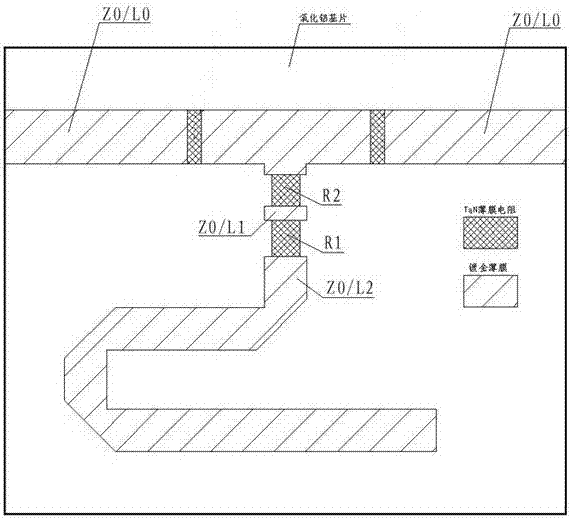

[0031] On the basis of specific embodiment 1, the equalization circuit, such as figure 2 As shown, including the balanced resistance realized on the open transmission line by adopting the microstrip open circuit stub + lumped resistance; the balanced resistance is realized on the alumina ceramic substrate with gold plating and TaN resistance film, and realized through the gold wire welding process The short circuit condition of the two balancing resistors.

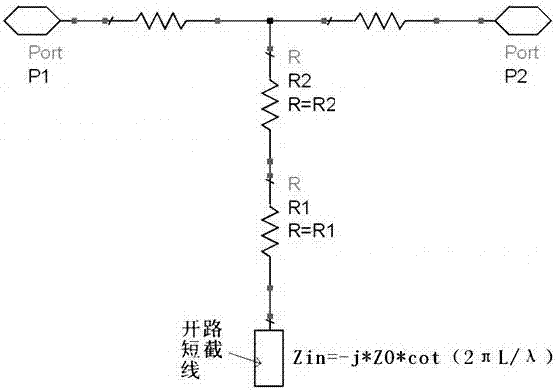

[0032] The equivalent circuit of the equalization circuit is as image 3 As shown, the working principle of the equalization circuit is that the input impedance of the open circuit stub is Zin=-j*Z0*cot (2πL / λ), where Z0 is the characteristic impedance of the transmission line, L is the length L of the open circuit transmission line, and λ is the microwave signal wavelength. When the length of the open-circuit transmission line remains unchanged, assuming that the wavelength corresponding to the frequency f0 is λ0, and ...

specific Embodiment 3

[0033] On the basis of the specific embodiment 2, the balancing resistor includes more than two series balancing resistors, and in this specific embodiment, includes two series balancing resistors R1 and R2. Using more than two balancing resistors in series can effectively improve the balancing accuracy, but the number of balancing resistors should be reasonably designed according to the influence of distributed capacitance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com